Five Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

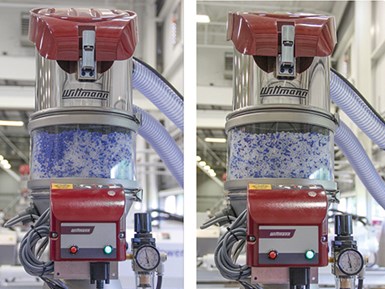

Photo at left shows a blend that has been conveyed 200 ft from the press. Notice that the mixture of white virgin material and blue colorant is uneven, as separation has occurred. Image on the right shows a blend that has been conveyed from beside the press, and the mixture is homogeneous.

With the rising cost of raw materials and tighter demands for product consistency, many processors struggle with blending their resin recipes. Re-introducing regrind into the final product is becoming more and more common, driven by environmental mandates and cost savings.

Here are five blending tips to help processors keep their material and labor costs down and aid in manufacturing a more consistent and compliant final product.

1. BLEND IT UP CLOSE

The closer the blender is to the processing machine, the more homogeneous the mixture of materials. Separation can occur when the blend has to be conveyed great distances before reaching the feed throat of the machine. This is the case when blending materials with different bulk densities and is especially true when blending regrind with virgin material, as the bulk density and size of the regrind can vary greatly. The inconsistency in bulk density causes the smaller, lighter pellets to separate from the larger, heavier pellets, resulting in uneven “layering” of material on the feed throat.

It is ideal to blend directly on the feed throat or above the feed throat on a mezzanine. If the blender must be located remotely then place it beside the machine or as close as possible. Also, a good-quality low-speed, high-torque granulator can help by providing a more consistent bulk density and regrind size with fewer fines.

This mixing bowl is equipped with static rings on the walls of chamber. These rings ensure that as material climbs up the walls of the mixing bowl due to static, the pellets fall back into the mixture.

2. SAY NO TO STATIC

Static build-up is a blender’s worst enemy. Static will cause material to stick to the walls of the mixing chamber, resulting in inconsistent batches. With low additive percentages, even a handful of pellets hung up in a mixing bowl can have a dramatic effect on the finished product.

With proper grounding of vacuum receivers and blenders, and using good-quality grounded hose, static build-up can be greatly reduced. Static rings on the walls of the mixing chamber are also essential to ensuring pellets fall back into the blend if static-charged pellets creep up the wall. Mixing chambers with a hemispherical geometry also help eliminate dead spots and material hang-up.

It is ideal to blend directly on the feed throat or above the feed throat on a mezzanine.

3. PAY ATTENTION TO RECEIVERS

The type of receiver on the blender hoppers can affect the accuracy of the blender. Volumetric and gravimetric blenders that rely on time only can be adversely affected by outside influences, such as pressure changes in the material hopper. A venturi or pressure cyclone style of separator receiver creates a positive pressure in the hopper. This will force material through the material hopper valve more rapidly, resulting in overdosing material during the receiver’s conveying cycle.

When a load cycle starts, this air cylinder is actuated, and the discharge bell is forced to make a perfect vacuum seal.

A gravity-style discharge valve on a vacuum receiver, most typically a flap, can create a negative pressure in the material hopper if the flap is leaking. This can result in underdosing material because of a slight suppression of material flow due to the vacuum created in the hopper during the receiver’s conveying cycle. Vacuum receivers with positive discharge valves help eliminate this, as the valve can positively close and seal with compressed air.

4. THWART THOSE BRIDGES

When working with “difficult” materials such as regrind, flake, or sticky additives, there is a chance the material can bridge in the hopper. Bridging materials will hinder blender performance because of lack of material flow. Valve size is crucial to help the flow of difficult materials; use larger hoppers if the blender is available with different hopper sizes.

Agitation of difficult materials is also an option to enhance material flow. Bridge breakers can be installed inside material hoppers; they pulse a knife-style actuator when the dosing valve pulses.

5. LEARN TO DEAL WITH REGRIND

Inside a blender material hopper, note that there are no valves in the way that could affect material flow.

One headache in blending regrind is either running out of it or having too much. It seems that no matter how hard you try, there is no magic blending recipe that will keep up with your regrind production without running out of regrind five minutes after you walk away. One method to help eliminate this is to use an intermediate regrind bin between the granulator and blender. This can help by storing surge during high- regrind production times and providing material during low-regrind production times.

Another approach is to vary the recipe on the blender relative to the amount of regrind production. Doing this manually is a time-consuming and tedious task. Use a blender that will adjust the recipe automatically depending on your regrind capacity. This type of blender uses a level switch to monitor the regrind level. This level switch can be mounted either in an intermediate hopper, or in the blender’s regrind material hopper itself.

Sensor on the blender hopper monitors material level for automatic selection of a high/low regrind recipe.

The operator sets two different recipes. For example: a high-level recipe may have a recipe of 40% regrind, 60% virgin, 2% colorant (the colorant is automatically calculated to relative to the 100% of virgin-plus-regrind material). As long as the regrind level stays above the level switch, this recipe will be used. If the regrind level drops below the level switch, a second, low-level recipe comes into play: It may have a recipe of 20% regrind, 80% virgin, 2% colorant. This will allow the regrind to build back up to the level switch again.

Analyzing and adjusting your material blending needs can go a long way towards reducing operator headaches, downtime, and rejects, and producing consistent, high-quality molded parts. Spending some time up front on your blending profiles will save you time and money in the long run.

About the Authors

Jonathan Fowler

Jonathan Fowler is the material-handling systems specialist for Wittmann, Torrington, Conn. Fowler has been with the company for more than six years, the last six months in his current role. Contact: (860) 496-9603 ext. 176;

jonathan.fowler@wittmann-group.com

Related Content

Automated Resin Management and Blending System for Tight Spaces

NPE2024: Designed for new and existing operations with up to 10 machines and limited available space.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

Read MoreProgram Provides Equipment Maintenance, Overhauls and Upgrades

NPE2024: Program aims to ensure equipment remains at peak performance levels throughout its life cycle.

Read MoreSmart Works Cells at the Heart of Wittmann’s Exhibit

NPE2024: Under the theme of “It's All Wittmann,” the supplier of injection molding machines, automation and auxiliary equipment is hoping to show NPE attendees what comes with true connectivity.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More