Auto Glazing: Film, Coinjection & Coating Technologies Advance

Hard-surfacing options for molded plastic glazing now include plasma instead of wet coatings–and replacing coatings altogether with in-mold film lamination or multi-layer coinjection.

The nascent field of injection molded polycarbonate car windows and sun roofs is fostering a proliferation of technological approaches for protective surfacing that provides scratch resistance or additional functionality such as heat and light blocking. New developments in plasma coatings compete with previous wet coatings, while in-mold and post-mold film laminating or multi-layer, multi-material injection present radically different approaches. Several of these new technologies were presented at a June conference on Automotive Glazing in Frankfurt, Germany, sponsored by the U.K. publications European Plastics News and Plastics and Rubber Weekly.

On the coating side, papers at the conference highlighted new developments in lower-cost or larger-scale plasma technology. Meanwhile, several industry experts discussed the benefits of laminating clear multi-material films or films reinforced with glass fiber or nano-fillers. Some presented film technologies that tackle problems such as blocking light and heat for larger parts like sunroofs.

Conference speakers also summarized the current state of market development. PC auto glazing is being used mostly in Europe for front and rear quarter widows, fixed side windows, rear-door fixed window sections, small transparent body panels, and larger panoramic sunroof systems. The drivers are weight savings of up to 50% and greater styling freedom than with glass.

Global demand for sunroofs for automotive applications is expected to rise from 15 million units in 2006 to 22.4 million units in 2010, according to data from the Freedonia Group Inc., Cleveland, and other sources. Total panoramic roof demand is expected to jump from 2% in 2003 to 40% in 2010, and molded PC will grab a share of this market, but improved surface protection will be essential.

Films go forward

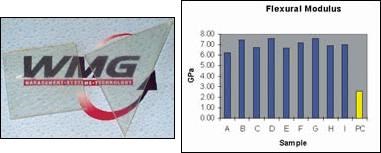

Up to now, the standard has been a hard coating applied after molding the PC substrate to provide scratch resistance and UV protection. But in-mold films might replace hard coatings, said Dr. Kerry Kirwan, assistant professor at the International Automotive Research Centre of Warwick Manufacturing Group (WPG), part of the School of Engineering at the University of Warwick in Coventry, England. Some of his research focused on laminated films that eliminate the need for wet or plasma coatings and provide better control of UV exposure along with high-quality surface finish and excellent impact properties.

One big benefit of in-mold film laminating is the ability to produce completely finished glazing right out of the mold. This approach could eliminate downstream coating operations while reducing the chance for scrap generation during parts handling.

In-mold film laminating also may offer molders a wider processing window. They may be able to run their machines at injection pressures and speeds similar to those used for back molding rather than under special conditions—such as an injection-compression process—required to mold the substrate under low-stress conditions in order to ensure both optical quality and retention of a hard coat.

Special PC resins have been developed for glazing, providing good flow and higher optical clarity than conventional materials, as well as adhesion to a hard coat. Some industry sources speculate that in-mold film laminating may allow use of more conventional PC resins.

“Transparent polymers are an attractive alternative to laminated or tempered glass, however no single polymer is ideal,” said Kirwan. His work at WMG focuses on various combinations of PC and acrylic in which the acrylic is a protective buffer. “Polycarbonate delivers excellent impact resistance but poor weatherability, while the acrylic brings excellent weatherability but lower impact strength. The combination of both is desirable but it is critical that the impact behavior of the polycarbonate is not unduly compromised,” Kirwan explained.

Kirwan tested a 100-micron acrylic film that was laid into a mold and back-injected with conventional PC. It reportedly afforded “outstanding environmental protection without loss of impact.” On the other hand, he noted, it may be undesirable to make plastic glazing too strong, preventing occupants of autos or mass-transit vehicles from escaping in case of an accident. One solution could be to using a blown rather than cast acrylic film, because blown film contains fine flaws created at the frost line in the bubble, which can serve as crack-initiation points when put into tension—i.e., from impact on the opposite side (inside the vehicle). Kirwan says this “directional failure” mechanism could permit passengers to escape while still providing vandal resistance on the outside.

Another approach to creating PC/acrylic “hybrids” in the mold is to use a coinjection process instead of film-insert lamination. “Simultaneous dual injection has never been used for transparent applications,” notes Kirwan, though two-shot injection has. WMG coinjected three-layer glazing with a PC core sandwiched between acrylic skins. “Interfacial adhesion can be controlled to provide different levels of impact strength,” Kirwan noted. He added that this removes process steps and costs associated with making and handling films and also offers greater design (shape) freedom.

WMG also investigated the development of glass-reinforced films for clear, structural parts. Glass reinforcements have not been used in transparent thermoplastics. WMG’s concept was to pre-wet woven glass with a clear, low-viscosity, transparent wetting agent. This prepreg can be placed on the outer surface of a part to deliver a maximum mechanical benefit and provide a hard surface. WMG developed a glass-reinforced system with a high level of transparency while keeping the manufacturing time to 4 min. WMG placed glass fabric covered with acrylic or polyester powder in a press between an acrylic film and a PTFE release film. Heat and pressure melted the powder to wet out the glass and squeezed out the air. The result was an acrylic film with glass on one side. This product could then be laid in a mold and back-molded with PC. So far, this approach results in some degree of haze.

WMG has also looked at the use of nanocomposite technology for glazing. Small amounts of nanoclay or metal oxide ceramic particles can be added to PC or acrylic. WMG found increased abrasion, solvent, and moisture resistance without loss of clarity.

Films for light control

Film laminates offer more than physical protection to PC glazing. They also can add functionality, said Joseph Harary, president of Research Frontiers, a U.S. supplier of light-control technology for glass and plastic glazing. This year, the firm’s global network of 33 licensees began sales of its second-generation SPD-Smart film technology for automotive, architectural, aerospace, marine, and other applications. Light-absorbing particles in the film instantly control visible light transmission from optically clear to very dark and also provide over 99% UV blockage and reduces solar heating of the car interior.

The film’s infrared and UV blocking characteristics can save energy by reducing the size of the air-conditioning unit required, said Harary. Reduced heat and UV exposure also reduces interior material costs. The film can also provide added strength, durability, and acoustic insulation.

SPD-Smart film with Research Frontiers’ patented Suspended Particle Device (SPD) technology incorporates an emulsion of microscopic, encapsulated poly-iodide liquid crystals. In an idle state, these light-blocking particles are randomly oriented in the film and block over 99% of visible light. When an electrical voltage is applied, he particles align so that light can pass through. “By regulating the voltage applied to the film, drivers or passengers can control the amount of light and heat coming through the window or sunroof,” said Harary.

SPD-Smart film is produced in rolls and at present is used only in laminate structures where it is sandwiched between two pieces of plastic or glass. SPD-Smart film can be bonded to PC with polyurethane adhesive. However Research Frontiers is working on using the film as the exterior layer in laminated PC glazing.

New coating approaches

Heat-cured wet coatings or lacquers based on acrylic or siloxane resins remain the most common approach for PC glazing and headlamp lenses. However, gas-phase deposition technologies such as chemical vapor deposition (CVD), physical vapor deposition (PVD), or plasma-enhanced chemical vapor deposition (PECVD) are becoming viable alternatives to wet lacquering, especially for large glazing parts, said Dr. Klaus-Dieter Nauenburg, sr. scientist at the Fraunhofer Institute for Chemical Technology in Germany.

With wet coating, it is easy to embed UV protection, but it can sometimes be difficult to get very good surface hardness, he noted. Users wanting higher hardness may have to switch from the low-cost organic resins like siloxanes to more expensive liquid siloxanes containing nano-particles. In addition, wet coatings involve solvents, which adds costs for environmental protection, Nauenburg noted.

Several vacuum-deposition coating processes exist, but their use with plastics at present is focused mainly on smaller applications such as eyeglass lenses and non-transparent decorative parts like automotive down-light reflectors. Nauenburg says that a plasma coating process is needed that keeps production costs low, has short process times, a high deposition rate, and large-area deposition capability.

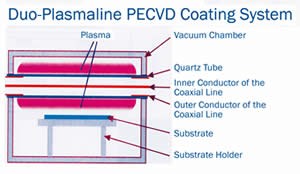

Two promising new technologies that may fill that void, he said, are a Plasma-Array system developed at the University of Eindhoven in the Netherlands and the Duo-Plasmaline deposition system developed at the University of Stuttgart’s Institute for Plasma Research (iPF).

The new Duo-Plasmaline PECVD coating system delivers high deposition rates of organic or inorganic materials (such as siloxane, quartz, or diamond) using a low-pressure, low-energy plasma generated by a linear source of high-frequency microwave energy. The low-energy system reportedly means low damage and low thermal impact to the substrate. Different gases can be used by the system, including hydrogen, oxygen, argon, or nitrogen. A 3-meter-long system has been built at iPF. Ongoing research is looking at ways to reduce or eliminate micro-cracking during thermal cycling and to achieve UV protection without pre-lacquering the PC.

The new Plasma-Array PECVD system carries out vacuum deposition of a hard, transparent, quartz-like film on PC in a solvent-free process. It has a deposition area of 80 x 60 cm and deposition rate of 1 to 3 microns/minute while holding thickness distribution to ±15% of target or tighter, said Nauenburg.

Plasma-Array PECVD hard coatings were deposited on pre-lacquered PC sheets. The lacquers were AS4000 and AS4700 from Momentive Performance Materials (formerly GE Silicones). Taber Abraser testing (1000 cycles) showed a haze increase of 47% for uncoated PC, 5.1% for AS4000 lacquered PC, and 1.8% for PC with AS4000 and PECVD coating. Delta haze for PC with AS4700 lacquer alone was 11% vs. 4.3% with lacquer plus PECVD coating.

Similar results have been obtained with the Exatec 900 multi-layer coating system, according to John Madej, CEO of Exatec, a former joint venture of GE and Bayer that is now a wholly owned subsidiary of SABIC Innovative Plastics (formerly GE Plastics). The Exatec 900 system, which has been in development since 2004, includes a proprietary siloxane wet coat followed by PECVD. According to Madej and data presented at the Frankfurt conference by application development manager Dr. Alex Scholten, 1000 Taber Abraser cycles produced a delta haze of >5% with the SHX siloxane wet coat alone and 1.8% with SHX plus PECVD.

Scholten and Madej noted that the full Exatec 900 system provides both scratch and UV protection and allows for intermediate printing steps in which inks and dyes can be applied for additional functionality such as light control, decorative effects, defrosting systems, and radio antennas.

Related Content

Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

Read MorePress-Side TCUs and Full-Plant Adiabatic Coolers

NPE2024: Frigel North America is launching RSY Syncro and RS/MD series, as well as new innovations in at-the-press and whole plant cooling.

Read MoreNext-Generation Workhorse Ultrasonic Welding Machines

NPE 2024: Rinco Ultrasonics’ line of standard ultrasonic welding machines significantly upgraded.

Read MoreDigital Signal Processor Power Supply for Ultrasonic Welders

NPE2024: Sonics launches Model DX800 for its DX Series OEM DSP Power Supply.

Read MoreRead Next

New Materials on a Fast Track for Molded Auto Glazing

Injection molding of polycarbonate automotive window and roof glazing is an emerging market that offers weight savings up to 50%, greater styling freedom and potential for parts integration (ribs or brackets) that glass cannot match.

Read MoreAuto Glazing: Window of Opportunity for Molders

This emerging market promises to be big but challenging. Polycarbonate car windows require specialized machinery, high-end processing capability, premium polymers, advanced coating technologies, and innovative mold and runner designs.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More