Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

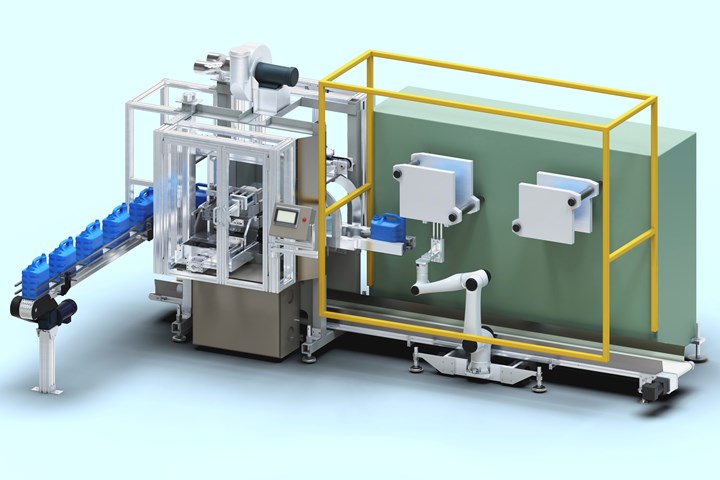

Updated Robopik bottle takeout system from Proco Machinery substitutes a versatile cobot for older fixed automation. Source: Proco Machinery

The next generation of Proco Machinery’s Robopik bottle takeout system is distinguished by its use of a jointed-arm collaborative robot (cobot), said to offer greater flexibility and adaptability than older fixed automation. The Robopik, designed for unloading and deflashing containers from shuttle blow molders, can be reconfigured easily to handle different types of products and adapt to changing production requirements, Proco says. The magnetically coupled cobot is said to also unload products faster and with greater accuracy than previous systems. The new system can handle delicate or irregularly shaped containers and minimize the risk of damage or defects.

It also features built-in safety features such as collision detection, emergency stop mechanism and protective barriers. Advanced connectivity enables seamless integration with other “smart factory” (Industry 4.0) technologies.

Related Content

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

-

Latest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.