Cobot Case Packer for Containers

Compact, mobile system with collaborative robot eases labor shortage for container packing.

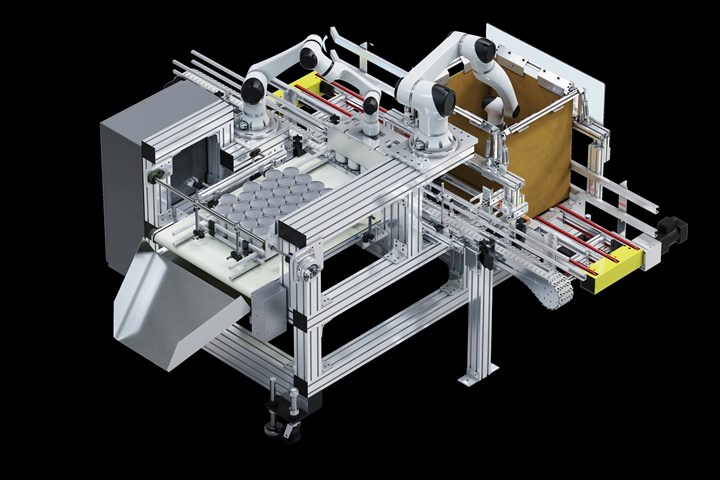

Integrated system includes accumulator, pick-and-place cobot, automatic box infeed and exit conveyor. (Photo: Proco Machinery Inc.)

A solution to labor shortages among packaging producers is offered by Proco Machinery Inc. in the form of the new Collaborative Robot Packer. This compact integrated system is highly flexible for handling a variety of rigid container shapes and sizes. Mounted on casters, the modular system includes a collating accumulation system with built-in bottle pusher, jointed-arm collaborative robot (cobot), automatic box infeed conveyor, automatic box exit conveyor and poly-bag vacuum feature.

The cobot is available in different models. It works alongside operators and is easy to teach for precise positioning of containers in different patterns and layers. Proco supplies end-of-arm tooling. The overall system boasts low capital cost, simple design with minimal moving parts, minimal setup, low maintenance and one-year payback, according to Proco. Large touchscreen controller can store up to 25 job recipes, such as all necks up, all necks down, or alternating rows of each.

Related Content

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.