Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

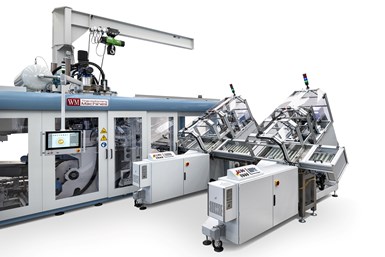

Based on a modular system, the Kiefel Speed Automation (KSA) system is matched to the Speeformer KMD series and can be integrated into existing and new machines. (Photo: Kiefel, div. of Bruekner Group)

Automation is an increasingly central trend in thermoforming equipment, owing to such factors as labor availability, higher-speed thermoformers that are restricted by the ability to handle parts at high speed, and demands for more stringent quality control. That’s the consensus among major suppliers of thermoforming equipment, all of which have emphasized automation in their recent equipment innovations and are at work to develop more.

Weighing in on this trend are Kurt Huelsman, president of BMG’s Nalle Automation Systems (NAS); Andreas Staudinger, Kiefel’s global director of polymer packaging; Gregory Romanski, WM Thermoforming Machines’ sales area manager for the U.S. and South America; Andy Fitzsimmons, SencorpWhite’s executive account manager; and, Conor Carlin, Illig North America’s managing director.

What’s Driving the Automation Trend?

Regarding the need to address low availability of labor and increasing speed of thermoforming equipment, SencorpWhite’s Fitzsimmons puts it this way: “These two forces combined have created significant demand for automated parts-handling solutions for our equipment. In fact, top speeds of thermoformers at this time are actually being restricted by the ability to handle parts at those speeds. This has added a sense of urgency to the already significant demand for higher outputs.”

Huelsman from BMG’s NAS says the lack of unskilled labor is impacting the ability to meet production output and deliver customer orders. He also noted the ROI for automation is now more attractive and that companies are exploring what they can automate on the back end of the machine. He adds, “Companies are looking for a competitive edge, and automation is one way to help do that. The market is looking for faster production rates with higher capacities, and automation can help support that with its ability to run with minimal downtime.”

Noting that many companies in both Europe and the U.S., lack the personnel to operate their machines, Keifel’s Staudinger says, “Our automation solutions enable maximum machine running times while reducing manpower requirements to a minimum.”

WM’s Lidpacker is a very compact solution with better handling and stability of lightweight products like lids. (Photo: WM Thermoforming)

WM Thermoforming Machines’ Romanski notes that since the pandemic, there is an even higher global demand for automation but the trend also depends on a country’s specific needs. “Worldwide, the U.S. market is currently leading the demand in automation, while in Europe, Italy has the lead as the Italian government already implemented their Industry 4.0 program, which includes fiscal incentives since 2017, increasing the need for improved machine efficiency and boosting integrated automation solutions. Overall most of our customers are considering major investments to automate their thermoforming processes to guarantee higher available machine ouput and efficiency.”

Both Romanski and Staudinger cite increased hygiene requirements. Says Staudinger, “Driven by the pandemic in recent years automation has become even more popular, as hygiene requirements for the production process have continued to increase. Contamination that could potentially be caused by manual grinding is eliminated.”

“In fact, top speeds of thermoformers at this time are actually being restrictedby the ability to handle parts at top speeds.”

Where Automation is Taking Place

Part removal and handling appears to be the key focus areas for thermoforming automation today. Huelsman says automating part handling at the trim press and end-of-line wrapping, case packing and palletizing had been challenging due in part to the wide range of products, limiting “universal” automation designs.

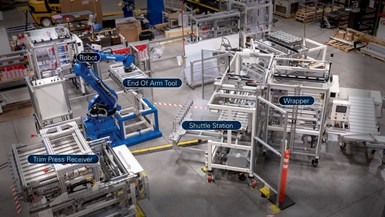

The Mantis from BMG’s NAS robotically removes product from the trim press and then transfers it directly to the wrapper/bagger. (Photo: BMG)

Noting that part removal (stacking and packing) of formed and trimmed products is of the highest priority, Huelsman points out that automation can free people from such repetitive manual tasks, which can be unsafe if not done properly.

Fitzsimmons notes that while the current focus is on part removal, as these solutions become more effective, downstream automation (stacking, bagging, boxing, etc) have become the next most requested add-on. “Note also that this automation also has a quality component that is being considered, as the speed of production is outpacing the ability to check quality at levels that are acceptable. Automation going forward will also have a quality system embedded in order to be effective,” he says.

Huelsman agrees: “Automating part handling creates a gap in the inspection process traditionally done by operators. This can be augmented by emerging vision inspection technology.” And Romanski adds, “We also see that part inspection technology is gaining major importance for our customers.”

Automation in New Equipment

All suppliers have enhanced automation in equipment offerings launched within the last couple of years. Most recently, BMG’s NAS launched the Mantis Robotic Trim Press Handling system, which replaces manual labor by robotically removing product from the trim press and then transferring it directly to the wrapper/bagger or the next phase of the system in place. Explains Heulsman, “New technologies such as Mantis use product-matching tooling to control and pull product through the handling process into packaging more effectively.”

Also new is BMG’s C-Rush Die-Cutter Handling system, which automates the process of removing sidewalls from vertical die-cutters and robotically places the sidewalls into work-in-progress containers. It is said to be easy to operate and designed to run 24/7.

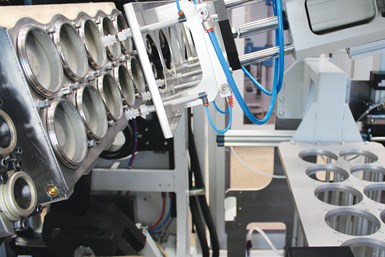

A Speedformer KMD unit integrated with a Speedformer Kiefel Speed Automation module, which forms full stacks from partial stacks such as food trays or lids.

Photo Credit: Kiefel, division of Bruekner Group

Kiefel’s newest automation solution is the Kiefel Speed Automation (KSA), a modular system that is matched to the Speedformer KMD series and can be integrated into both new and existing systems. It provides intelligent, modular automation solutions suited to the most common applications, which contain fewer product-specific format parts and can still be optimally adapted to customer requirements. According to Staudinger, this allows the production of packaging on various modules to be automated and modernized, offering high product-design flexibility.

One KSA module forms full stacks from partial stacks — e.g., of food trays and lids. Another module takes cartons from a box magazine, erects them, and inserts a protective bag for hygienic packaging if required. The packaging stacks are automatically inserted into these bags. As soon as the carton is full, the bag and carton can be automatically closed and transported onwards as required.

The KSA range also includes an automatic labeling unit. The palletizing unit consists of two stations, making it possible to palletize in one station while the other is being emptied. If the products are not to be packed in cartons, the sleeving module can be used, in which one or more stacks are packed and shrink-wrapped. Some of the automation modules can also be integrated into the Speedoformer KTR series tilt-stacking machines.

Says Staudinger, “Automation plays an essential part throughout the whole process. A highly qualified team implements automation for every production step for packaging, from unrolling and heating the plastic film, to stacking and packing the products, palletizing the finished packaged units, and quality control along the way. Even options for waste disposal or recycling can be adapted: Industrial film waste can be shredded directly for further processing or wound up on a roll. The special feature of all this is that the automation units from Kiefel can not only be smoothly integrated into the company's own steel-rule and tilt-stacking machines. They can also be connected to machines from other manufacturers. Customers do not necessarily have to completely replace their entire systems, but can retrofit them. This is so attractive that around half of Kiefel automation systems are installed on competitor systems.”

From WM Thermoforming Machines, is the recently updated MSv stacker with the integrated Lid Packer—this one developed in concert with Imanpack of Italy to guarantee a stable process from the forming to packaging in only three steps. Romanski notes that it is especially designed for use with the company’s tilting machines, and is especially suitable for small, lightweight products produced on those machines such as lids and DIP cups. (Here is a video of WM Thermoforming automation in action.)

The customer now benefits from a compact solution, better handling and increased product stability during the whole process, according to Romanski.

“Automation plays an essential part throughout the whole process. Therefore, a highly-qualified team implements automation for every production step for packaging.”

According to Fitzsimmons, SencorpWhite has moved from the simple parts- handling systems (“stackers”) to a fully automated solution that stacks, picks and places parts on a conveyor and delivers them quickly and safely to the packer.

In 2019, Illig launched what was billed as one of the most powerful thermoforming systems then available — the fourth-generation RDM 76K automatic roll-fed machine, which features PH 76 handling and downstream automation, including sleeving and case packing. The completely redesigned double-servo drive of the RDM 76K ensures shorter movement times and faster cycle speeds up to 42 cycles/min.

Illig also improved the material-handling system. The electronic parallelism setting of upper and lower table reduces setup times, which adds to higher availability. The integrated tool-block change system reduces tooling times to less than 1 hr. According to Illig’s Carlin, “Even with an extended oven, the total length of the line is shorter than the previous series, due to the integration of the newly designed PH 76 product-handling device, which allows direct interlinkage with different end packaging solutions, such as sleeving and case-packing. The overall movement times of the Illig system are faster than previous generations leading to higher output of a wider range of parts with lower energy consumption.”

WM's MSv stacker with the integrated lid-packing system was developed in concert with Imanpack to guarantee a stable process from forming to packaging in only three steps. (Photo: WM Thermoforming)

Automation Advances Underway

Efforts toward further automation are also underway at equipment suppliers. From part handling to case packing to palletizing, increased functionality, smaller footprints, and greater ease of use have driven more robotics into traditional applications, according to Huelsman. His firm is currently building a new robotic palletizer: “This is a collaborative robot with a higher reach (108 in.) and a higher payload (50 lb) than most, if not all, competitors. It has a very small footprint, taking up little space in comparison to traditional palletizers. This product also does not require physical guarding, only sensors.”

WM is currently working on new developments to provide integrated automation systems for their FC models (continuous steel-rule machines). Says Romanski, “At this time, the available automation solutions for this type of machines are still quite limited due to reduced flexibility (product handling as a result of the product geometry), maximizing machine throughput, limited available production space as well as covering specific packing requirements from our customers. These limitations are forcing companies to continue to hire a high number of packers and rely and rely on other semi-automated solutions which result in reduced overall production efficiency.”

Sencorp, according to Fitzsimmons, is working towards higher-speed parts handling as well as downstream automated packing.

Staudinger says Kiefel is striving to make its automation solutions more modular. “This will enable us to offer an even more tailored range for customers for any production volume, particularly for our proven Speedformer KMD systems.”

Related Content

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreAI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More