Bag ‘Commander’ Brings Innovation And Service to Can-Liners

Aluf is a huge supplier of industrial and consumer can liners that—despite its size—is fast, flexible, and customer responsive.

During the economic downturn of some years ago—a time most in plastics would like to forget—many industry leaders pondered what the processor of the future would look like. That is, what types of companies would emerge from the brutal economic downturn. One popular school of thought held that surviving companies would either have to be big and diverse or small, niche-y, and extremely customer-centric.

But could one company be both? In many respects, that describes Aluf Plastics, a leading blown-film processor supplying retail/commercial can liners and industrial packaging film from a 500,000 ft² plant in Orangeburg, N.Y. Aluf recently expanded with acquisition of an 80,000 ft² plant in Sulphur Springs, Tex. In a business where volume generally rules the day, you don’t see that many hundred-million-dollar companies with more than 80 blown-film lines willing to satisfy a customer with an order of just a few thousand pounds.

Aluf is a certified woman-owned business, run by Susan Rosenberg, that opened shop in October 1977, first in Clifton, N.J., then Edison, N.J. The company was so named because the Hebrew translation of Aluf is “commander,” recalls Joseph Rosenberg, v.p. of sales and part of the company’s second-generation management group. (The firm still offers a Commander line of products.) After a fire in Edison, Aluf rented and subsequently purchased the Orangeburg plant.

STRENGTH IN NUMBERS

Today, Aluf employees more than 300 people in New York, where it operates more than 70 mono- and three-layer blown-film lines, along with another 12 in Texas. Annual sales exceed $100 million, says Rosenberg, and have increased in 14 of the last 15 years. Aluf has a 24-hour-a-day operation. It processes more than 120 million lb of material, about 75% of which is LLDPE, with the remainder HMW-HDPE.

On top of that, it has four reclaim lines equipped with proprietary degassing technologies for post-industrial scrap—much of which Aluf purchases—that produce proprietary blends around the clock. Many of the reclaim lines are fewer than 10-years old. Susan R. Rosenberg, Aluf’s president and CEO since 2008, notes, “Aluf operates with a strong focus on green. The fact is, we’ve been involved in recycling long before it became a buzzword.”

The company has been acknowledged twice by Inc. Magazine as one of the fastest-growing privately-held companies in the U.S. It is also reportedly the only bagmaking company that has been honored for its excellence in customer service twice by the International Sanitary Supply Association (ISSA), Northbrook, Ill.

In Texas, Aluf purchased a facility and equipment that was previously owned by a film processor that went out of business. “We have enough land to significantly expand the facility,” remarks David Anderson, Aluf’s v.p. of operations.

Anderson adds, “We purchased seven lines from the acquisition that were not up to our technology standards, so we did a major rebuild. We also upgraded the facility to meet AIB (American Institute of Baking) standards and set up a QC department for food-packaging film in particular.”

“Our expansion into Texas represents yet another milestone in the growth of Aluf Plastics,” says Susan Rosenberg. “It expands our distribution to existing clients throughout the Southwest, while bringing new distributors and retailers into the Aluf family.”

The firm is growing in New York as well. Its processing operation there is fed by enormous outside silos, and Aluf is laying the foundation to accommodate three more, says Anderson, adding that the site can accommodate up to 20 railcars. Over the last five years, Aluf has added 15 lines. Its strategy is primarily to buy American and European lines. Most are equipped with internal bubble cooling and automatic gauge control. Aluf also uses multi-component gravimetric blending systems.

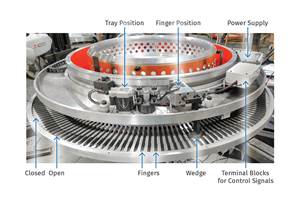

All lines feature a controls package Aluf designed in tandem with Sysmetrics, a company based in Israel that focuses on materials handling, conveying, and blending; as well as an MES system tailored specifically to extrusion. “Controls is another area we have focused on in recent years,” states Joe Rosenberg.

Of its installed capacity in Orangeburg, about 60% is devoted to trash bags, with the rest aimed at industrial packaging film. “Rollstock is a growing category for us,” says Nathan Celnik, v.p. of industrial packaging. The company supplies film for a wide range of applications that include form-film-seal, wide sheeting, and many different bags for the poultry, steel, and air-freight industries, he adds.

About 40 of its lines are dedicated to producing HMW-HDPE products, the rest are LLDPE lines that swing from one product to the next. “We turn over those lines on a dime,” says Susan Rosenberg.

For can liners, the plant is divided into HMW-HDPE and LLDPE areas. Some are set up in-line with bag-making machines. In other cases, such as with its draw-string products, the bags are produced off-line from master rolls.

“Our draw-string machines are extremely fast, faster in fact than our extrusion capacity. And we have extrusion lines that run up to 2000 lb/hr,” Anderson explains.

Aluf also uses an innovative robotic packaging and palletizing system. Each case is weighed before it’s placed a pallet. The cases are also barcoded, so a product that is off-spec can be traced to the line and shift during which it was produced.

Aluf is extremely versatile for such a large film operation. Its product line consists of about 1000 SKUs. In the industrial can liner market alone, it offers 120 different kinds of 55-gal bags alone. In trash bags, meantime, it produces more than 50 different types of 13-gal bags. Aluf’s products are run in blowup ratios from 2:5:1 to more than 3:1 and range in thickness from 0.23 mil up to 7 mil, a testament to the versatility of its product range.

About 60% of Aluf’s can-liner business is private labeled. But Aluf has been expanding into more branded products, developing its own line of consumer bags. One new line of branded bags is called Harmonyx. They are white on the inside and black on the outside, in 13-gal tall kitchen bags, and 30- and 39-gal trash and lawn-and-leaf bags. As Susan Rosenberg explains, Aluf opted to offer two-color bags because while consumers have a preference for white bags, an all-white bag does not obscure the trash. Harmonyx bags are three-layer products that range in thickness from 0.9 mil (kitchens) to 1.1 mil. They are furnished in a patent-pending, self-dispensing, tube-shaped container.

Other branded product lines Aluf offers include Ultrasac trash bags (white, black, blue, or clear) in sizes from 8 to 60 gal and gauges from 0.35 to 4 mil; Ultrasac Value Line Bags (white, black and clear) for tall kitchen and lawn/leaf applications in thicknesses from 0.6 to 1.05 mil; Ultrasac Commercial contractor bags in 33, 39, 42, and 55 gal and thicknesses from 1.4 to 4 mil (with at least 90% recycled content). Aluf also recently introduced the Ultrasac Platinum line of branded kitchen, trash, and lawn/leaf bags from 0.9 to 1.1 mil thick that are formulated for maximum performance and strength with antimicrobial agents that inhibit the growth of odor-causing bacteria on the bag.

As with most three-layer can liners, Aluf uses recycled content in the core layer. But as Susan Rosenberg points out, the company is expanding in coextrusion primarily because it provides more opportunity for innovation. “We’re utilizing more three-layer technology not to bury scrap, but to drive performance by improving properties and responding to consumer demand.” she explains.

SERVICE FIRST

Aluf might be big, but it isn’t clunky. It will accommodate orders as small as 2000 lb, states Joe Rosenberg. It keeps an astounding $5 million worth of inventoried products, and can deliver from that stock in three days. Its lead time on custom jobs is about two weeks.

But for Susan Rosenberg, it’s about quality and service. And that’s not just lip service. “While we have been quite absorbed with growth and innovation and have developed many revolutionary products, we’ve worked hard to develop an industry-wide reputation for integrity and responsiveness,” she says.

She adds, “Yes we are large. At 500,000 ft² in Orangeburg, we operate the second-largest blown film plant under one roof in the U.S. But it’s all about the customer. What needs does the customer have? What can we do to meet those needs? That was certainly a consideration in the expansion to Texas. That move will give quicker access to a broader base of customers.”

Related Content

Materials Suppliers Team on PFAS-Free Solutions

Baerlocher PFAS-fee process aid passes muster in resin manufacturer’s testing on production-sized blown film line.

Read MoreFlexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreBreaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More