Building Your Welding Arsenal

A combination of micro-TIG and laser welding technology should cover all your bases in mold repair.

Welding technology for mold repair has changed in the last decade. The industry standard used to be TIG welding, a technique that is still used for many repairs that require buildups of 0.060 inch and more. However, laser welding has changed the landscape of mold repair, because it can produce smaller welds than a TIG machine. Both processes have strengths and weakness that complement each other, and that is why most professional weld shops use both. Here is a brief overview of these two main welding processes and purchasing considerations:

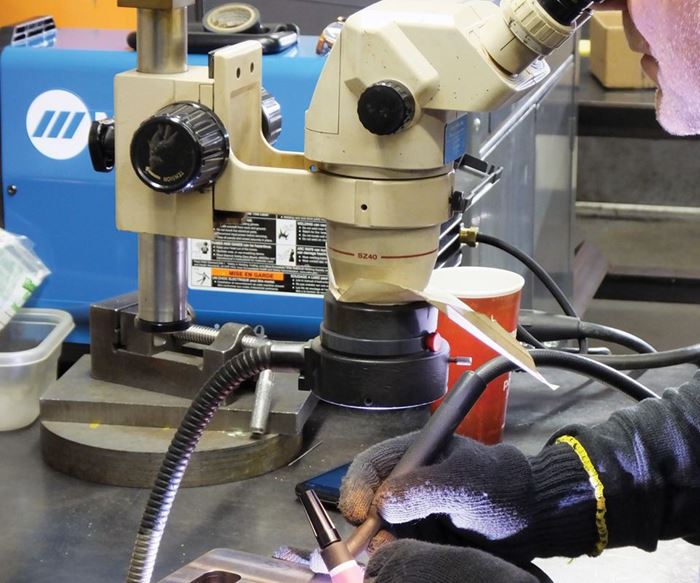

Micro-TIG welding. A micro-TIG welding setup consists of a specialty TIG machine with a low-amperage TIG torch used under a microscope. The microscope allows the operator to use smaller diameter filler to create welds as small as 0.010 inch, depending on the application. The machine is considered specialized because it is designed to operate at a much lower amperage than a regular TIG machine. Welding at a lower amperage means that a smaller weld puddle is formed, which is critical for creating small welds. Power is delivered from the machine to a welding torch through a power cable that also carries the shielding gas, which protects the weld from oxygen contamination (see Figure 1).

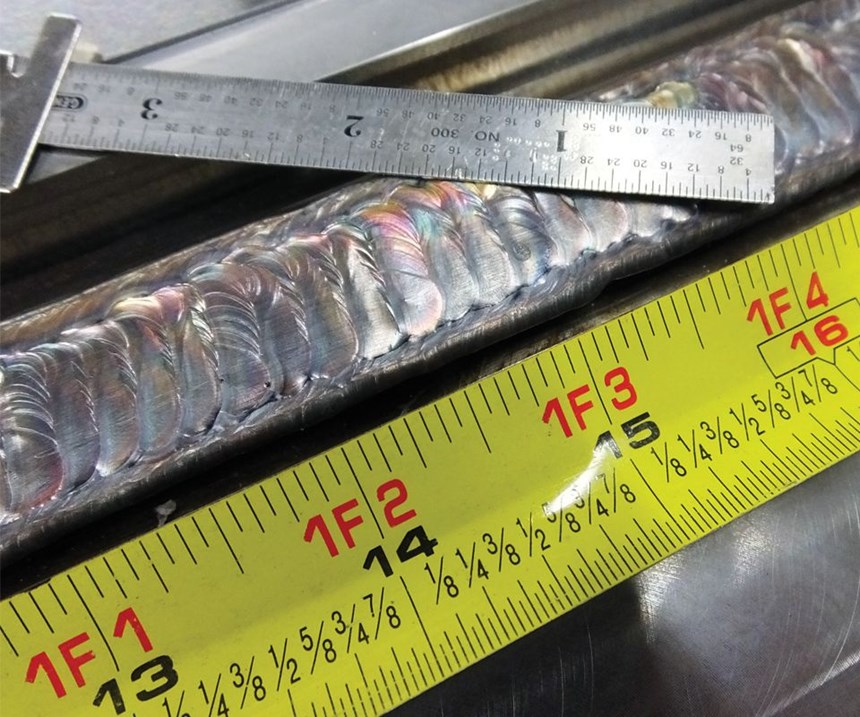

The strength of the TIG welding process is that it can fill deep holes and rough areas, and create large buildups (see Figure 2). Micro-TIG welding can weld small, but laser welding is capable of welding even smaller, with less risk of accidental damage and distortion to the workpiece. The reason for this is the arc of the micro-TIG welder may wander from the electrode of the welding torch during the process, damaging sensitive details around the weld area. Also, a TIG-weld puddle (regardless of the size) heats up to a couple thousand degrees Fahrenheit, which can cause distortion and damage to small molds and inserts during welding.

Experience is the most critical component to micro-TIG welding success. It is very difficult to become a proficient micro-TIG welder with no welding background, because the operator has to learn the basic steps, such as starting an arc, before he or she can progress. One becomes a micro-TIG welder by becoming a proficient TIG welder first then moving to a special mold-welding microscope for practice. However, learning to weld under a microscope takes time, as the welder gradually learns about depth of field and positioning. Consultants are available who can help train already-established TIG welders in the fundamentals of micro-TIG welding.

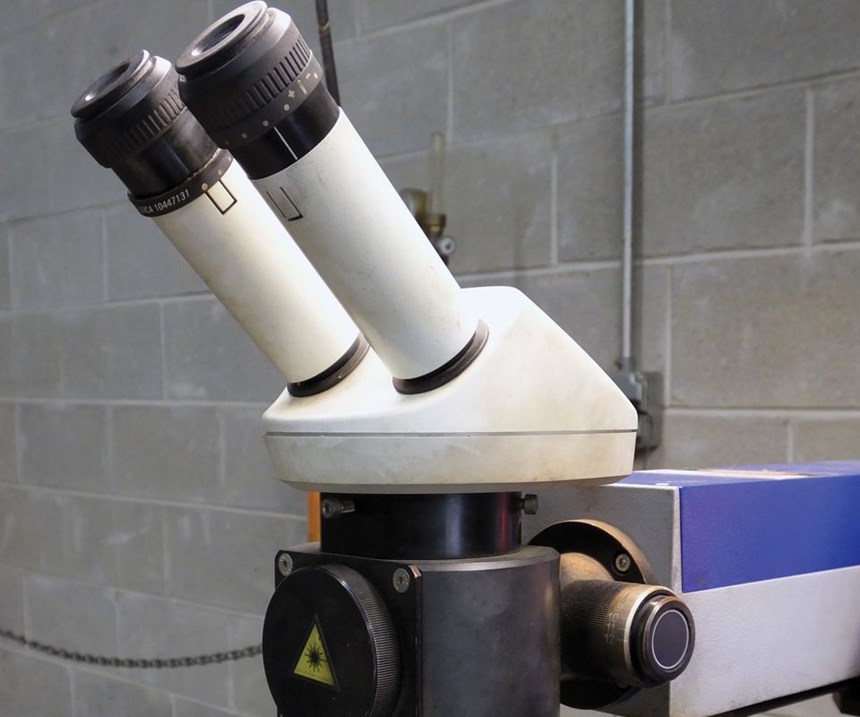

Laser welding. The laser welding process begins with lining up the weld area in the crosshairs of the microscope. When the laser is engaged, a weld puddle will form in the center of the crosshairs. At this point, filler is added.

Instead of using an arc generated from a welding torch, laser welding uses a wavelength of light. The laser beam is generated from a fixed point, typically an extension or arm attached to the machine’s power base (see Figure 3). The laser can be a neodymium yttrium aluminum garnet (Nd:YAG) type that disperses a pulsed light at a wavelength of 1,064 millinewton (mn). A microscope is also attached to the arm and allows the operator to see extreme detail, similar to a micro-TIG microscope.

The laser creates a pulsed microscopic weld puddle that allows pinpoint weld deposits of a couple of thousandths of an inch. When the laser pulses, a weld puddle is formed that can be seen under the microscope. When the laser is not pulsing, a weld puddle does not form, allowing the workpiece to stay cool. This is why laser welding has a low heat displacement, which is critical for minimizing any welding sink or distortion. The duration and size of this pulse can be adjusted.

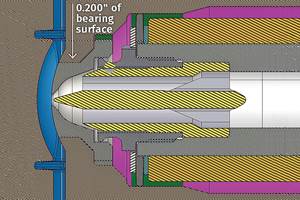

There are some drawbacks to laser welding. For example, this process is very specialized. In my welding shop, it is used for very small repairs. Plus, it can be time-consuming, depending on what is being repaired. Most often, my laser welding projects involve repairing shut-off areas (see Figure 4).

Most professional mold weld shops are skilled in both processes, and designate laser welding

or TIG welding depending on the job and customer preference. Many times, both processes are used on the same job. For example, the speed of TIG welding can be used to

repair a large area and then the low-heat capabilities of a laser welder can be used to fix any distortion around the weld.

Buying a Laser Welder

There is a trend today towards mold builders adding or expanding their mold repair capabilities to serve their customers better, and having access to both TIG and laser welding technologies is key. Here are a few considerations before investing in a welding machine:

Laser welding is easy to learn, at first. A shorter learning curve doesn’t mean a welder will be an expert in a matter of weeks. Like everything, it takes time. Welding a flat surface is simple, but welding an edge or a detail around sensitive areas takes time to master. Most laser manufacturers will be able to provide training to help the welder master the basics, as well as share advice on more challenging repairs.

Understand the machine’s capabilities. Research the capabilities of each machine of interest, including its power, maneuverability and cost to maintain. Seek advice from people who have experience in the field. I recommend not purchasing a machine under 120 watts, since this is too low in power to successfully perform consistent mold repairs. Also, copper-based and aluminum materials require higher power ranges to do repairs because of the inherent nature of these materials.

Laser welding cannot completely replace TIG welding. Large areas of damage will require such a heavy weld buildup that using a laser welder would be too time-consuming and inefficient, such as a damaged area that is 1/4-inch high and wide. Although this can be laser-welded, TIG-welding would be much faster. This is why the welder needs access to both processes, either through an in-house machine or an experienced outside TIG-welding source.

Keep up with technology and new information. Always search for current information on the latest products and equipment to discover more efficient and cost-effective ways of performing mold repairs. Laser technology is constantly evolving as laser welders get more powerful, so it’s smart to keep up on industry trends and technology.

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreHot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More