Chiller Sets New Benchmarks For Energy Efficiency, Tight Control

Coming in July, a new chiller line boasts up to 50% energy savings and ±0.5°F temperature control.

Here are more details on what is heralded as “the most efficient industrial process chiller on the market,” first discussed briefly in last month’s Keeping Up section. Jochen Naujokat, president of Delta T Systems, Richfield, Wis., and Rick Holzhauer, the firm’s chief mechanical engineer, previewed this development exclusively for Plastics Technology. These units are loaded with features that are either “firsts” in the field of process chilling, or are still quite rare for smaller chillers, or are standard capabilities that are usually expensive options.

To be launched in July, the new line will start with small portable chillers of 1 to 15 tons, with larger portable models up to 30 tons and central models to follow thereafter. Initial models will be air cooled, though water-cooled units will not be far behind.

SAVING ENERGY, BIG TIME

Perhaps the most important innovation in these new chillers is variable-speed compressor technology, which has been used for 20 years in the HVAC industry but rarely before in process chilling. (The only other known example is NQV series of 10- and 20-ton portable chillers introduced by Thermal Care, Niles, Ill., at NPE2015. See June '15 Keeping Up.)

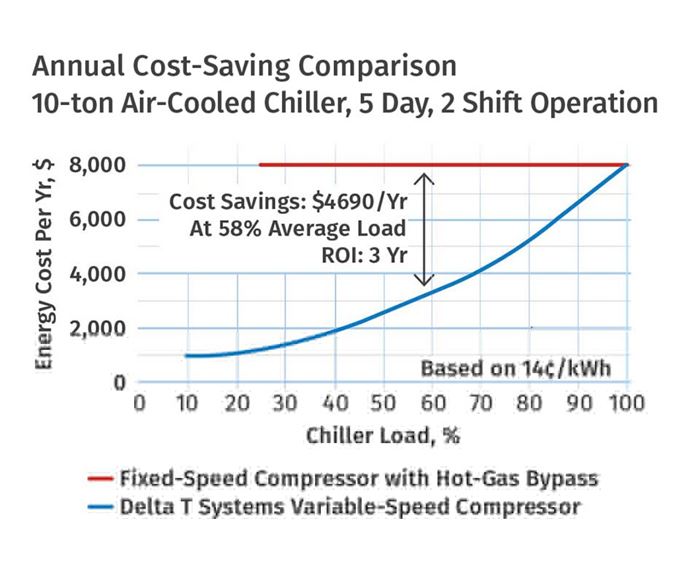

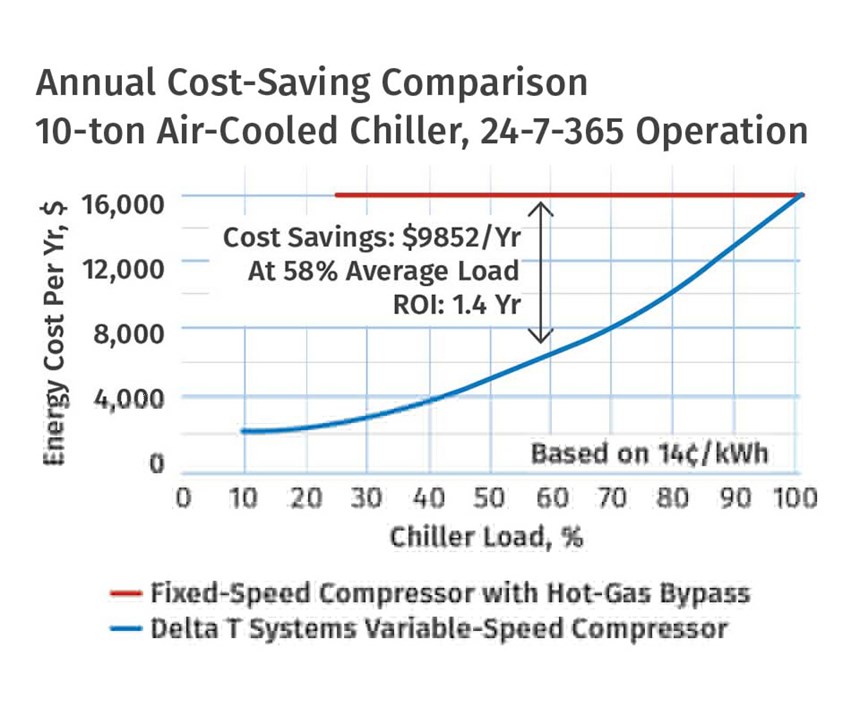

The new Delta T system monitors the process temperature and signals the drive to speed up or slow down the compressor. It eliminates the wear and tear of on/off cycling of the compressor or energy- wasting hot-gas bypass valves. Compared with conventional fixed- speed compressors with hot-gas bypass, the new technology uses up to 50% less energy, according to Delta T Systems, or 30-50% of the initial investment, and thereby pays for itself in two to three years. Naujokat says these estimated savings are conservative because “Most chillers are selected based on the peak-usage time of the year, which means the chiller is oversized for the average use.”

The savings are analogous to the savings from variable-speed hydraulic pump drives vs. standard fixed-speed pumps in molding machines. Like a conventional fixed-speed hydraulic pump, a fixed-speed compressor runs at 100% of the rated load regardless of the process needs. A more advanced option is the hot-gas bypass valve, which vents the hot, compressed refrigerant gas to the evaporator if no cooling load is needed. This is wasteful in the same sense that a conventional fixed-speed hydraulic system dumps excess oil over a relief valve when not required by the process.

According to Naujokat, variable-speed compressors have historically been designed for HVAC use, and only recently have models tailored for industrial chilling become available. A key requirement for industrial versions is a wider operating envelope, Holzhauer explains. Another element critical to the development of the new chillers was that Delta T Systems Inc. worked with controls manufacturers to create a system specifically for use with these compressors.

The controller continuously monitors the suction and discharge pressures to ensure the compressor stays within its operating envelope. However, that operating envelope is now between 10% and 100% of rated capacity, which means that a 10-ton chiller can operate efficiently at loads of 1 to 10 tons. That compares with a 30% to 100% operating range for conventional chillers, says Naujokat.

Another new energy-saving feature is an electronic expansion valve, which works with the variable-speed compressor to tune the valve to the system needs based on data from temperature and pressure sensors. The valve is driven by a DC stepper motor, which moves a pin up or down to allow more or less refrigerant to flow through the valve. Up to now, this technology has been available mainly on larger chillers of 20 tons or more capacity. (It is also used on Thermal Care's NQV series small portable chillers.)

The new chillers also use variable-speed condenser fans, which use onboard sensors to monitor the refrigeration system to keep the fan operating at the most efficient point. What’s more, monitoring the refrigerant discharge pressure also protects the compressor by helping to keep it within its operating envelope. The variable-speed condenser uses a permanent-magnet, electronic computated motor (ECM), described by Delta T Systems as “the latest development for condenser-fan motors and the quietest, most efficient, and most reliable motor technology in the industry.” It eliminates the small copper refrigerant capillary tubes from a mechanical expansion valve or mechanical pressure controls that can fail over time due to vibration, Holzhauer explains. ECM is another feature adopted from the HVAC industry, and variable-speed fans have until now been relatively rare in process chilling, where they have been offered as expensive options—but are standard on the new units from Delta T Systems.

Also contributing to efficiency are oversized, stainless-steel, brazed-plate evaporators with a larger heat-transfer surface than competitive units, which reduces compressor demand and energy consumption. And microchannel aluminum condenser coils eliminate the galvanic corrosion between dissimilar metals seen in copper-tube coils with aluminum fins. Microchannel aluminum coils are “the latest technology in the industry,” according to Naujokat, and have appeared so far on only a few industrial chillers.

In addition, cleanable condenser air-inlet filters to protect the condensers from dust and debris are standard features on the new chillers but not on all competitive models. Delta T Systems also added a cleanable evaporator strainer to protect the evaporator channels from clogging; unlike similar features on other chillers, it employs a new method of straining and a quick-disconnect on the water side that eliminates threads and hose clamps.

Like other state-of-the-art chillers, the new units also have a refrigerant filter/drier and all nonferrous chilled-water piping that won’t rust.

ENHANCED CONTROL & CONNECTIVITY

Besides energy savings, the number-one benefit from the combination of variable-speed compressor and condenser fan, plus electronic expansion valve, is better temperature control—within ±0.5° F vs. a more typical claim of ±1° F or C, and Naujokat says a real-world practical value today is often more like ±2-3° F

He notes that the new chillers use “adaptive control,” whereby the compressor speed is adjusted to prevent a shutdown if it approaches an alarm condition—caused, for example, by increased refrigerant discharge pressure due to dirty condenser coils. The issue would be indicated on the control display with a short troubleshooting message, and an email or text message could be sent automatically to notify maintenance personnel.

The controls feature a compressor soft start, which adds to longevity, along with the fact that repeated compressor on/off cycles are eliminated by the variable-speed motor.

The new control system collects a large amount of data through digital sensors—including suction and discharge pressures and temperatures, water in/out temperatures, tank level, pump pressure, drive and fan outputs, pump status, compressor amps/volts/phase monitoring, and alarms. Such extensive data collection is usually offered on central chillers and is not typical of smaller portable units, Naujokat notes.

He adds that his new chillers’ remote communication option—either through Modbus to a plant management computer or PLC, or via the internet (“cloud”) to a remote PC, tablet, or phone—is also unusual for smaller chillers. This Industry 4.0 capability is standard in the new units, not an expensive option.

Pricing has not been set for the new chiller line (dubbed "VS" for the variable-speed condensers), but Naujokat says it will not be premium priced, though the units may cost slightly more than standard models of the same size, a difference he says will be made up for quickly by energy savings. The two accompanying charts show expected savings and ROI for a 10-ton chiller operating 24-7 and 5 days/2 shifts, based on energy cost of 14¢/kWh.

Related Content

Hot Oil Temperature Control Units Expand Heating Capacity and Flow Rates

Thermal Care’s Oiltherm hot-oil temperature control units (TCUs) extend heating capacities up to 90 kW and flow capabilities up to 50 gpm.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Read MoreIndustry Vet Duff Joins ACS Group

With 37 years of experience on both machinery and processor side, Michael Duff to handle aftermarket business for auxiliary equipment manufacturer.

Read MoreTemperature Control Units on Display at PTXPO

technotrans says climate protection, energy efficiency and customization will be key discussion topics at PTXPO as it displays its protemp flow 6 ultrasonic eco and the teco cs 90t 9.1 TCUs.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More