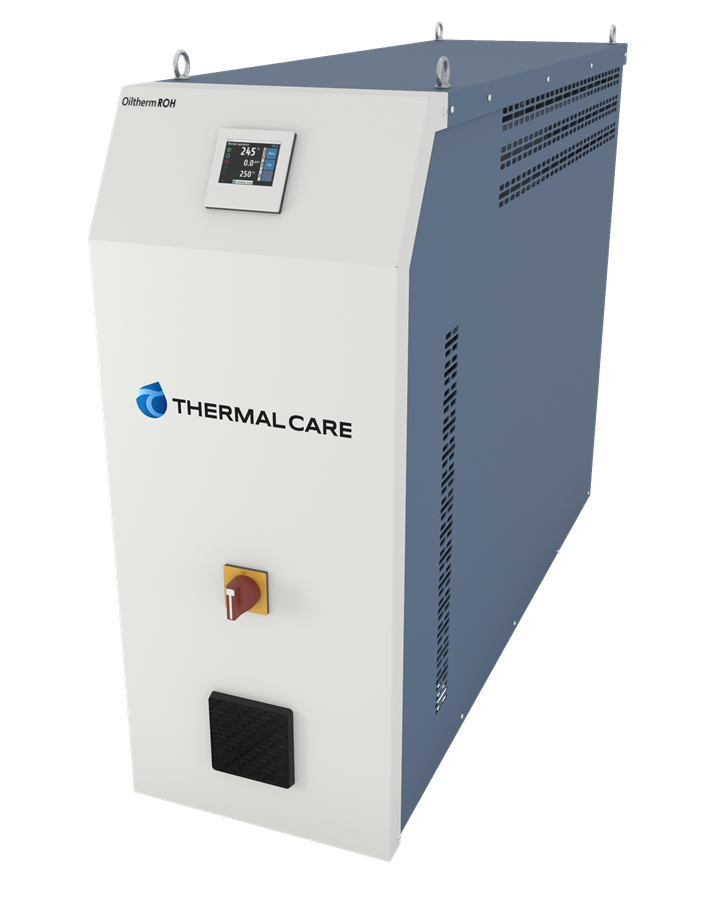

Hot Oil Temperature Control Units Expand Heating Capacity and Flow Rates

Thermal Care’s Oiltherm hot-oil temperature control units (TCUs) extend heating capacities up to 90 kW and flow capabilities up to 50 gpm.

Thermal Care has introduced the Oiltherm ROH Series of hot-oil temperature control units (TCUs), which in addition to expanded heating and flow capabilities, feature a touchscreen control. The Oiltherm ROH Series has extended its heating capacities up to 90 kW and flow capabilities up to 50 gpm.

The design features forced circulation of flow around the heating element, which enables higher capacities and reduced thermal oil volume while maintaining a safe maximum temperature. The magnetic‐driven pump, which is standard, enhances efficiency without relying on mechanical seals, which can be prone to wear.

The unit features a color 3.5" touchscreen which, in addition to control, displays information to monitor the process, including actual and set point temperatures along with flow, pressure and heat/cool ratio data.

Thermal Care says the ROH Series controller also incorporates ramp programming and supports various interfaces, including TTY, ethernet IP and Profibus. It also provides remote control capabilities via smartphones or PCs — upgraded features that were not available on the previous generation of Oiltherm units.

Thermal Care says the Oiltherm ROH Series of hot-oil temperature control units features greater heating capacity and heating medium flow. Photo Credit: Thermal Care

Related Content

-

PiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

-

Water Temperature Control Upgraded and Integrated into Machine Control

Engel’s new eco-flomo temperature control system continuously monitors injection mold cooling and temperature control circuits, displaying pressure, temperature and flow rate values.

-

Follow These Best Practices When Working With Heat Transfer Fluids

Effectively choosing, operating and maintaining thermal fluid can positively impact productivity in plastics processing.