Close the Loop on Clean Cooling Water

A plastics molding plant runs on more than electricity—it runs on water.

A plastics molding plant runs on more than electricity—it runs on water. Clean water. Lots of it. Consider even a small plant with three 165-ton and three 120-ton hydraulic injection presses. Each typically requires a continuous supply of 100 gal/min to cool the hydraulic system and the mold. Assuming a two-shift operation, that’s 96,000 gal a day and more than 30 million gal a year! With that much water going through a plant, water quality has a direct and significant impact on the plant’s operations.

Dirty water blues

Water contamination can have serious and costly effects, such as equipment damage and even failure, not to mention worker health problems. Heavy particulate matter and corrosive agents in process water can wreak havoc on your plant’s productivity.

The following conditions suggest that your plant is suffering from water contamination:

- Clogging of high-heat, low-flow areas.

- Clogging and/or corrosion of process components.

- Gelatinous deposits.

- Worker health complaints such as fever, chills, coughs, muscle aches, headache, tiredness, loss of appetite, and even pneumonia.

Most water-contamination problems result from the open-loop process cooling systems common in U.S. plastics plants. An open-loop design means that your molds and other process equipment are exposed directly to whatever contaminants are present in the water supply. If you have a cooling tower, additional contaminants can enter the water from its repeated exposure to the outdoor air.

If you have an open-loop process cooling system design, you must regularly monitor and treat your water supply to control lime scale and other mineral deposits, as well as corrosion, microbiological growth (algae, bacteria, fungus, and molds), and accumulation of suspended solids such as airborne dirt and debris that are washed into the cooling-tower water.

In addition to the cost of water monitoring and treatment, an open-loop process-cooling system burdens your plant with costs for sewage disposal and equipment maintenance, plus the cost of water usage. These operational costs—not to mention intensifying environmental regulations—have become an increasingly significant management challenge to plastics processors.

Close the loop

Manufacturers are coming to recognize that recycling their process water will not only reduce water costs, it can also forestall contamination. Water recycling is accomplished by closing the loop between the process and the source. This can be accomplished with a closed-loop cooling tower or a water chiller of either central or portable type.

A closed-loop system is similar to a conventional open-loop system except that in a closed-loop system, the tower reservoir is usually constructed with two separate tanks. One tank holds process water that is piped to the process and back to its tank without coming in contact with the tower water. The second tank holds the tower water, which—in a completely separate loop—circulates to the tower cell and back to the reservoir tank. The two loops are connected through the medium of a plate-and-frame heat exchanger, in which heat is transferred from the process water to the tower water.

Closed-loop systems eliminate common water-related problems because—once it is initially filtered and chemically treated—the water remains pure.

Cleaner water through closed-loop process cooling means increased manufacturing uptime and higher production rates because of the lower risk of fouling. There are many other benefits, as well:

- Lower energy costs due to improved heat transfer capacity.

- Reduced equipment maintenance requirements—generally limited to once-a-year cleaning of the heat exchanger.

- Improved protection from chemical water treatments because chemical loss is decreased.

- Once the system is filled, the amount of make-up water required to maintain volume is small, reducing direct water costs.

Appropriate material selection for components of a closed-loop system is critical to safeguarding against contaminants. Galvanized metal sheets offer good protection, but once sheets have been cut, drilled, welded, and formed, areas are exposed to attack. Even the smallest unprotected areas can lead to corrosion at a rate comparable to that of unprotected mild steel.

Although they are relatively costly, non-corrosive materials such as stainless steel, copper, and PVC or HDPE plastic should be used for piping and reservoirs. The heat exchanger should always be stainless steel.

A closed-loop process-cooling system constructed of corrosion-resistant materials categorically prevents the introduction of contaminants to process water and is the single most effective way to forestall avoidable equipment deterioration.

| IF YOU'RE EXPERIENCING... | YOUR WATER COULD BE CONTAMINATED BY... |

| Scaling | Minerals such as calcium, magnesium, silica. |

| Clogging of critical system components | Corrosive inorganic products such as iron oxide, which migrate to high-heat, low-flow areas. |

| Corrosion of metal components | MIC (Microbiologically Influenced Corrosion) comes from organic or inorganic acids, alkalis, or reducing agents such as hydrogen sulfide or ammonia produce byproducts that are corrosive to mild steel, stainless steel, copper alloys, or galvanized steel. |

| Gelatinous deposits on metal surfaces | MIC, which mixes with other contaminants to form biomass that prevents corrosion inhibitors from reaching the metal surfaces. This is commonly referred to as underdeposit corrosion. |

| Poor worker health | MIC ----------------------------------------------------- Organic debris (tree seeds, leaves, insects, pollen, grass, bird droppings), which enter the system and decompose in the relatively warm water—creating a nutrient-rich environment for bacterial growth. |

Laura Walker is the director of sales and marketing for Cooling Technology, Inc. a manufacturer of process-cooling systems in Charlotte, N.C. She can be reached at (704) 596-4109 ext. 219 or by e-mail: lawalker@coolingtechnology.com. She extends her appreciation to John Henderson, district manager of ChemTreat, Inc., a firm specializing in industrial water treatment, for his contributions to this article. He can be reached at (704) 591-4345.

Related Content

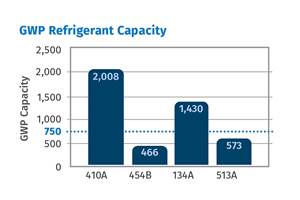

Temperature Control: What You Need to Know to Comply With New Cooling-Fluid Regs

Beginning the first of this year, 12 states are following EPA bans on potentially damaging cooling fluids. Chiller suppliers have adjusted equipment designs to accommodate the new regulations. Here’s what all this means to processors.

Read MoreACS Group Adds Regional Sales Manager

Richard Gutierrez named Southwest regional sales manager.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Read MoreConair Names New Head of Customer Care

Jared Helfrich to direct the efforts of the machine builder’s growing customer care group, combining its existing parts and service and repair organization with a new range of fast-growing customer services.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More