'Collar Joining' Method Makes Plastic-Metal Hybrids

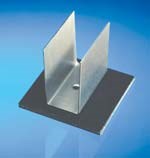

A mechanical method for joining plastic and metal to create hybrid automotive front-end assemblies has been developed by BASF AG in Germany.

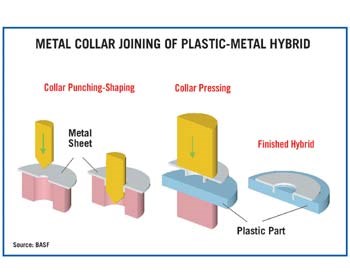

A mechanical method for joining plastic and metal to create hybrid automotive front-end assemblies has been developed by BASF AG in Germany. The approach is to form projecting annular "collars" in a metal sheet and then to cold-press those collars into parts. Undercuts in the metal collars act as claws to firmly lock together the sheet metal and molded plastic.

"Our new assembly system is simple, reliable and cost-effective," declares Dr. Ulrich Endemann, head of BASF's application research for hybrid systems in Ludwigshafen, Germany. Hybrid technology is gaining ground in automotive front-end development because it realizes cost, weight, and space savings not possible when plastic or metal are used alone.

Metal collar forming is a two-step process using standard metal-shaping tools to punch holes in the sheet and draw and shape these into collars with undercuts to enhance joining strength. BASF reports that about 1100 lb of force are needed to press a 5-mm-diam. collar into a typical plastic part.

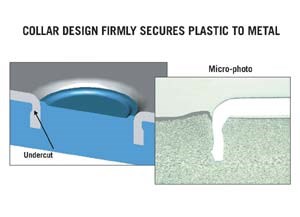

Endemann says extensive testing of BASF's collar-joining approach shows the method works well with a number of reinforced and unreinforced materials, including nylons, PBT, and polypropylene, although most work to date has been with 30% glass-filled nylon 6 and 66. He says the pressing step uses low enough speed to impose no impact shock on the plastic. Micro-photography reveals no significant crazing or fracturing when metal collars are pressed into the plastic. Finally, this joining method is unaffected by any stress relaxation in the plastics that might occur during use.

BASF reports that tests of its hybrid joining system are under way in several collaborative programs covered by non-disclosure agreements. Commercial applications are expected to emerge soon. The technology is also available from BASF Corp. in North America.

Competitive advantages

BASF claims that collar joining provides advantages over other means of plastic-metal joining. One approach patented a decade ago by Bayer AG in Germany involves overmolding glass-filled nylon 6 onto selected areas of sheet-metal inserts placed in an injection mold. The plastic flows through holes in the inserts to form strong, rivet-like joints. Other suppliers, including Rhodia in France and Dow Automotive in the U.S., have developed methods involving secondary steps like heat staking, riveting, and adhesive bonding.

Collar joining is said to make parts with strength comparable to overmolded hybrid structures while also realizing potential for space and weight savings. "Our approach allows designers to utilize the plastics more efficiently," states Endemann. One reason is that collar joints can be positioned anywhere along the margin between metal and plastic, reportedly providing increased freedom that allows optimal distribution of the plastic. According to Endemann, placement of joining points in overmolded hybrids is limited due to gating and hot-runner design requirements in the tool as well as the requirement that parts must be demolded in one direction only.

In terms of cost, Endemann says collar joining offers simpler tooling and shorter cycle times for injection molding because the metal insertion step is eliminated. He claims that for most high-volume applications, these benefits outweigh the added cost of metal-forming presses and assembly robots required for collar joining.

BASF claims advantages over adhesive bonding methods too, including the "LESA" system developed by Dow. LESA (low-energy surface adhesive) allows long-glass reinforced PP to be bonded to steel without primer or pretreatment. Dow claims its system makes possible a closed-box design of front-end carriers, which in turn is said to enhance front-end impact performance. BASF argues that its method can realize similar results while avoiding the cost of adhesives and meeting any relevant health regulations.

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreOptical Sorting for Color Flexibility in Recycled Plastics

Aaron Industries added optical sorting to its operation, expanding capabilities to meet the color needs of customers.

Read MoreBuilding a Future With Sustainable Compounds

With roots in recycling, Star Plastics produces engineering thermoplastic compounds to meet performance and environmental goals.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreRead Next

Long-Glass PP Makes InroadsIn Automotive Front Ends

Injection molded, long-glass-reinforced polypropylene appears to be the staple of new automotive front-end systems (FES) designed with a high degree of parts integration.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More