New Robotics From JEC 2004 Speed Up Composite Molding Process

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

New approaches to robotics and mechanization introduced at the Paris JEC show in April are speeding up composite molding processes from spray up to thermoplastic compression molding. Other highlights included tools designed for "instant" heating and faster cooling, numerous innovations for RTM and vacuum infusion, plus a host of new reinforcements.

Robots lend a hand

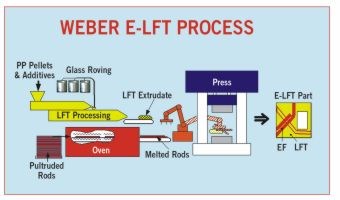

Esoro AG, an engineering firm in Faellanden, Switzerland, and Albert Weber GmbH, a supplier of auto engine components in Markdorf, Germany, showed a new process they call "E-LFT" or endless long-fiber thermoplastic. The patented process was also presented at the recent SPE ANTEC meeting in Chicago.

It’s a one-step way to make high-strength, lightweight, low-cost structural parts by using pultruded rods of polypropylene and 65% glass as a means to introduce continuous unidirectional reinforcement into thermoplastic long-fiber compression molding. A jointed arm robot places preheated rod sections in the tool, where they are overmolded with a molten charge of chopped long-fiber PP compound (30% glass). Molding heat and pressure flattens out the pultruded rods as if they were unidirectional tapes. A sample automotive rear seat back for Audi was exhibited. The seat back weighs half as much as an equivalent steel part and can be made in 90-sec cycles with all trim waste recyclable. Esoro does the engineering and design of the E-LFT parts, while Weber, the patent holder, molds the parts. Commercial production is expected to begin by 2007.

Robots also assisted thermoset composite fabricating at JEC. Composite Systems Inc. from the U.S. showed its robotic lay-up system for the first time. Its PFE system uses standard commercial robots and up to 56 different end-of-arm attachments for a wide variety of tasks. It’s part of Composite Systems new flexible mobile factory that reportedly can build wind-turbine blades on site at competitive cost, saving transportation time and expense. Composite Systems is installing its first flexible system at the Aerospace Manufacturing Technology Center of the National Research Council Canada in Montreal.

The U.K. division of Liquid Control Corp. recently built for a European customer a battery-powered truck with a 5-meter-long boom to spray two-component gel coats into a mold for a 50-meter-long wind-turbine blade. The self-propelled truck replaces a bucket brigade of up to 25 people that were previously required to gel coat such large parts within a limited time.

The boom truck carries 200-liter drums and the company’s Twinflow meter-mix machine to spray epoxy or acrylic gel coat at up to 40 lb/min. Previously, the company built two smaller trucks with 3-meter booms. One went to a customer in Spain and the other to the U.S.

Wolfangel GmbH in Germany developed what is believed to be the farthest-shooting spray nozzle in the world. The pump creates pressures of up to 4350 psi and shoots liquid resin or gel coat over 2 meters into a mold. The high-pressure gun chops glass from continuous roving and mixes it with resin externally. Wolfangel also worked with a unit of ABB in Lubljana, Slovenia, to develop a robot to spray gel coat automatically onto molds for yacht hulls, reducing overspray by maintaining a constant spray distance over an 11.5-meter horizontal range.

Molds heat, cool fast

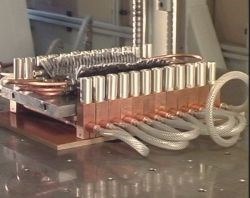

French moldmaker RocTool SAS, which has a U.S. office in Atlanta, speeds up closed-mold cycles by heating only the mold surface to a depth of less than 1 mm, not the whole mold. This shaves 30% to 40% off cycle time and avoids the energy cost to preheat and cool the whole mold.

RocTool uses inductive heating of a thin coating of a special alloy that forms the surface of the tool. It is backed up by a different metal. A movable cage of inductors creates an electromagnetic field around the mold to heat the surface almost instantaneously. (For certain mold shapes, inductors can be placed temporarily inside the tool.) Cooling is also very quick, thanks to placement of cooling channels in the tooling very close to the thermally conductive surface. Molds can thus be quickly cycled from hot to cold.

The tooling concept can be used for a variety of closed-mold processes and both thermoplastic and thermoset materials. RocTool has won prizes for its patented concept for several years, but demonstrated a commercial system for the first time at JEC, where it molded Twintex co-woven PP and glass-fiber mat (a product of Saint-Gobain Vetrotex) in tooling heated to 425 F (maximum is 450 F) and an 80-sec cycle instead of 5 to 6 min for a conventional process.

RocTool is now prototyping tooling for 10 projects. It will license its process and make molds and/or prototype/precommercial parts. A test production line will be available for customer trials late this year.

Pyromeral SAS in France offers high-temperature Pyromer ceramic binders that can impregnate any type of reinforcing fibers and be used to make laminated molds that can withstand high temperatures (up to 1000 C). Pyromer composite molds have been made with integral heating and have been used for making thermoplastic-composite boat hulls. Pyromer ceramics cure at temperatures below 200 C and cure times are adjustable from minutes to hours.

Vacuum infusion and RTM

Tackling the problem of voids in vacuum infusion of large parts, MAN Technologie AG in Augsburg, Germany, showed a prototype of a casing for an Ariane booster rocket that could be made in two composite segments, replacing seven much heavier steel pieces. The carbon-fiber composite is made with a new patented vacuum infusion process that uses a semi-permeable membrane to create void-free laminates, MAN says. The new process had not been used commercially at show time. Aerovac Systems Ltd. in the U.K. introduced a heated vacuum bag for vacuum infusion and a special glass reinforcement in which resin travels through the glass itself without the need for a separate resin infusion veil. Aerovac doesn’t market the materials in the U.S., but could transfer the technology to another firm. Aerovac also introduced VacFilm 4004, reportedly the widest film on the market for vacuum infusion—8 meters without a splice.

Richmond Aircraft Products Inc., a U.S. sister company of Aerovac, also introduced wide vacuum-bagging films—up to 6.1 meters—along with a new low-cost sealant tape for vacuum infusion of large parts like wind-turbine blades.

Several companies showed new faster-filling infusion materials. Flemings Textiles Ltd. in Scotland introduced a new 3D core material called Polymat Hi-Flow that reportedly fills 50% faster than current materials for RTM and infusion molding. It also uses less resin because resin flows more evenly, Flemings says. The core is stitched into a sandwich between layers of chopped glass mat.

As reported previously (visit the Article Library on our website and see May ’04 Keeping Up with Composites), Owens Corning in Toledo introduced new Continuous Filament Mat 8635, tailored specifically for infusion molding and reportedly filling 25% faster than previous continuous-filament products.

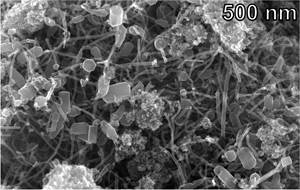

Cytec Engineered Materials Inc. in the U.K. won a prize at JEC for its 3-D Priform technology, launched last year, which overcomes previous limitations on toughening vacuum infusion resins. According to Cytec, the low viscosity required for the process precludes use of standard toughening agents within the resin. Instead, Cytec incorporates the toughener as soluble thermoplastic fibers that are co-woven with carbon or glass reinforcements at a 10% to 25% level. When a low-viscosity epoxy thermoset resin is injected, it dissolves the thermoplastic fiber, dramatically improving the toughness and fire/smoke properties of the epoxy, Cytec says.

Glas-Craft Inc. showed a new computer-controlled RTM injection system for polyester resins that controls pressure and catalyst feed. It allows catalyst feed rate to increase gradually during molding to speed cycles by providing a faster gel for resin that enters the mold last. Radio frequency I.D. tags allow an unlimited number of part recipes to be stored.

New fabrics and more

Advanced Composites Group in the U.K. (U.S. offices in Tulsa, Okla.) introduced a novel prepreg form in which the reinforcement is coated with stripes of resin instead of all over, making air removal easier for large parts. Air can be drawn away in a simple vacuum-bagging operation heated to 65 C, instead of requiring a high-temperature autoclave to achieve zero internal porosity, the supplier claims. Cycles are also said to be faster.

Lantor B.V. in the Netherlands developed a new nonwoven fabric called Soric, which acts as both a core material and infusion medium, as well as a "print blocker" if needed. It consists of flat hexagons stamped out of a sheet of polyester nonwoven and then arranged in rows between layers of nonwoven veil. It resembles a honeycomb but has no empty cells—instead, there are empty spaces between the solid hexagons. Pressure-resistant Soric sheet is available in thicknesses of 2 to 6 mm. U.S. distributor is Alcan Baltek.

MGI Canada Inc. showed a new proprietary process that fills a honeycomb core with urethane foam. (Typical cores use foam or honeycomb, not both.) The material is made in blocks and machined into sheets or shapes.

Zyvax Inc. of the U.S. introduced a new mold release, Flex-Z, designed specially for stickier low-VOC resins. It is a system of six color-coded products with different levels of release. They can be wiped, brushed, or sprayed on different areas of the same tool at one time. Flex-Z is suited for open- and closed-mold processes from wet lay-up to RTM and vacuum infusion.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More