Compounder Finds Niche in Recycling

Combining compounding and recycling in one step is helping take Buckeye Polymers to the next level.

Buckeye Polymers, Lodi, Ohio, is a plastics compounder with multiple manufacturing, sales, and service facilities located throughout the U.S. and Canada. Established in 1995, the company owns its own recycling operation in Sebring, Ohio, for producing raw materials from post-industrial and post-consumer feedstocks. Buckeye entered the recycling side in 2000 due to the new demand for recycled content in automotive applications, says Ron Chislow, Buckeye president and COO. The automotive market represents about 55% of its revenue. Other markets served include construction, housewares, industrial, and toy markets.

With more than 120 employees, Buckeye Polymers produces compounds in the polypropylene product family, including TPEs, TPOs, reinforced PP, and impact PP—all of which can be based partly on reprocessed materials. “Buckeye is roughly 65% recycled, with some compounds being 100% virgin, some at various mixes of virgin and recycled resins, but no 100% recycled content,” Chislow says. “Each compound is a proprietary formpulation that is made for specific properties requested by the customer, so we still count on virgin resins.”

Buckeye has five extrusion lines in its Midwestern operation and the company also has three recycling/wash lines in its 55,000 ft² Sebring facility. The company’s on-site physical-property testing facility provides Certificate of Analysis documentation for all its products.

INVESTING IN TECHNOLOGY

It’s not enough to simply maintain momentum—to stay ahead of the competition, it’s necessary to invest in new technology. But it must be done wisely. After all, what’s the point of spending excess money on things you think you need but don’t actually use? This is why Buckeye spent time evaluating the market prior to adding another extrusion line. The process to purchase a new line began about three years ago. That included a visit by Buckeye representatives to Austrian machine builder MAS, represented here by eFactor3, Charlotte, N.C. Buckeye decided to work with MAS after seeing its machines running.

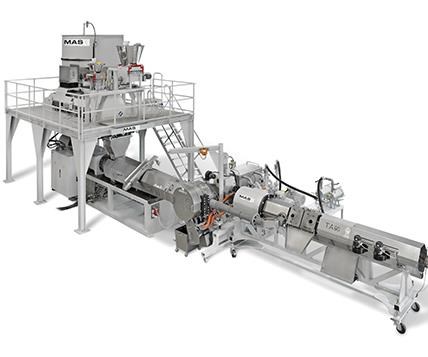

The equipment purchased by Buckeye includes a MAS 90 Cascade system with the CDF 500D melt filter. The system was delivered last May. The MAS 90 system is a co-rotating conical extruder with continuous melt filtration and “cascade” discharge extruder. The system is designed specifically for reprocessing and compounding recycled materials in one step.

The OneStep extrusion system made its North American debut at NPE2012 in Orlando, Fla. The new system brings together the plastication and homogenization abilities of a parallel, co-rotating twin-screw extruder with the advantages of a conical twin-screw (which is typically counter-rotating). Due to the conical design, the intake volume is significantly greater than the discharge volume, resulting in an extremely high screw filling level, MAS claims. “This leads to high throughput per revolution with excellent melt-pressure stability and at the lowest possible melt temperature,” according to the company.

MAS says excellent results are achieved, even when compounding high volumes of fillers, like calcium carbonate. A single entry aperture is used to feed all materials. Complex arrangements of multiple feed ports, which are typical for parallel twin-screw compounders, are unnecessary, according to MAS. In compounding 60% PP film flake and 40% powdered additives, a specific energy consumption of only 0.24 kWh/kg is easily achievable, the company claims.

CONTINUOUS MELT FILTRATION

Wood and paper are very common impurities in plastic recycling. Conventional filter systems using mesh screens are usually unable to cope with even small amounts of such impurities. The continuous CDF-type melt filter reportedly separates contaminants such as paper, wood, aluminum, or rubber efficiently. A scraper removes the contamination from the surface of a rotating screen disc. The impurities are discharged continuously from the CDF, while the filtered melt is forwarded to the pelletizing system. Melt pressure in front of the filtration disc automatically controls the function of the disc and scraper system.

“The machine is very different from a conventional extruder with its additional filtration of the polymer, making it ideal for removing contaminants from extrudate,” Chislow states. “The cascade extruder then provides another location to remove volatiles before pelletizing.”

After installing the new MAS extrusion line, compounding capacity at Buckeye Polymers is now 41 million lb annually. The new machine is processing three proprietary PP compounds for automotive and housewares customers. Depending upon the bulk density of the material, Buckeye is experiencing rates between 2500 and 2750 lb/hr.

The new extrusion line is the only machine that runs exclusively recycled-content compounds. At the Lodi facility, extrusion lines can run either virgin or recycle.

NEW PARTNERSHIP

Last year, JyTech Polymers Inc. (JTP), Ann Arbor, Mich., announced plans to install a custom compounding line for thermoplastic vulcanizates (TPVs) within the Lodi facility of Buckeye Polymers. Headquartered in China, JTP provides custom TPV compounds to Asia-based automotive weatherseal manufacturing operations. The compounding operation will utilize Buckeye’s post-consumer PP and is expected to be on-line this year.

“The relationship with Buckeye will give JyTech Polymers a fast, solid foothold in North America,” says Shawn Jyawook, JTP COO. “We’ll be able to immediately expand relationships with our tier 1 and tier 2 compound customers.” Although recipes are customized, JyTech’s core compound has already been OEM-validated, allowing each customer to specify its own unique grades without having to repeat the OEM approval process.

“Buckeye’s post-consumer feedstock has properties and stability similar to virgin material, and has already been validated by the automotive OEMs,” Jyawook states. “At the same time, JyTech will bring Buckeye increased TPV compounding capacity, advanced weathersealing expertise, and an entry into Asia if that can help Buckeye better service its core customer base. The excitement is mutual.”

Related Content

How to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreFilm Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More