Conveying Elbows Handle 40% Glass-Filled Nylon

Lighter and cheaper than cast alternatives, new stainless-steel conveying elbows utilize a plastics-specific geometry and proprietary internal coating to withstand filled materials.

One week before he spoke with Plastics Technology, Dave Grable found himself on the platform above a press, squeezing the conveying line to diagnose any weak points in the elbow by feel. Considering the abrasiveness of the material (40% glass-filled nylon) and the volume being injection molded (1000 lb/hr), Grable, the maintenance and support manager at Novares, wanted to evaluate how the newly installed RaBend elbow from Vactec was holding up. Grable’s placement of the new 90° elbow had been an intentional stress test to vet the new technology at Novares’ Janesville, Wis., facility. Novares, formerly Miniature Precision Components (MPC), is headquartered in Walworth, Wis.

“I thought I’d put the RaBend in an area where I am really going to prove it out,” Grable says, “and it’s been performing flawlessly. She’s been running strong for a year and a half right now, and I always go up there and feel it. You try to find if there’s a weakness in the metal by pinching around the diameter, and ... nothing—this thing is still rock solid.”

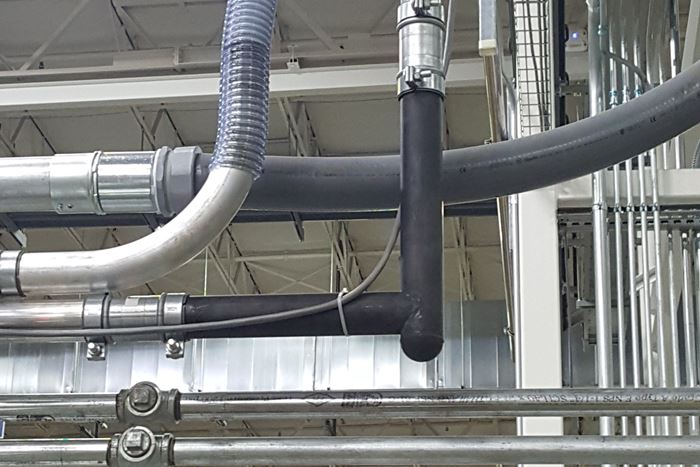

Created by Vactec LLC, a consulting firm started by materials-handling guru Chuck Thiele, RaBends were specifically designed for plastic conveying as an alternative to long-radius or cast-alloy elbow designs. The RaBend consists of a “T” where one end of the crossing section is shorter, with a hemisphere end piece welded onto that short end to cap it off. As material enters the RaBend, it’s carried to the pocket formed by the T’s short leg, which extends past the 90° corner and is capped by the hemisphere. The hemisphere pocket creates what Vactec calls a “heel” of resin, against which conveyed material impacts, resulting in a change of direction without pellets impinging against the wall. The hemisphere, which replaces a flat blind “T,” creates a cyclonic cleanout, according to Vactec. For installation, RaBends connect directly to conveying tubes with normal bolted couplings and don’t require special flange connections or adapters.

Vactec sells an abrasion-resistant (AR) version of the elbow, featuring a proprietary treatment called NiTec, which raises the hardness of 304 stainless steel from 29 to 65 HRC. Vactec says the NiTec adds only 0.002-0.008 in. to the inner diameter, and unlike ceramic or enamel coating, it cannot flake off and damage downstream equipment.

Grable says that RaBend’s performance at Janesville impressed him enough to use the new elbows from silo to press in the company’s new Morrison, Tenn., plant, which is installing a central material-handling system and will also be running highly filled engineering resins.

“The majority of what we push through the system is a glass-filled nylon and it can wreak havoc on anything’s that aluminum,” Grable says. “Aluminum doesn’t have a prayer with it; stainless steel will give up the ghost in probably two months—it will have a hole in it.”

Grable is confident enough now in the RaBends that he doesn’t plan on having to clamber up to inspect conveying lines anymore at Janesville or at Morrison, once the new material-handling system is installed. “It’s gotten to the point where we don’t even look up at the elbow anymore,” Grable says. “To me it’s a headache I don’t have to worry about.”

Related Content

Fundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More