Creating a Mold-Repair Plan-Part I: The Mold Layout Sheet

Regardless of mold type, the goal of the maintenance shop always is the same: Get a mold production-ready after it has been removed from service.

Regardless of mold type, the goal of the maintenance shop always is the same: Get a mold production-ready after it has been removed from service. Given today’s climate, with manufacturing jobs migrating to foreign soils faster than you can flash a parting line, the objective can no longer be only getting a mold ready. To stay competitive, mold maintenance needs to be more effective and performed faster, using less tooling and fewer man-hours. Accomplishing this is not magic and does not require expensive technology or complicated systems. Instead, it depends on improving communication, analyzing accurate historical data, acquiring sound workmanship habits, and continuous training.

Smart mold builders and designers alike keep one eye on maintenance issues that affect the productivity of their molds. Like any service provider, they want their molds to run reliably and efficiently with maintenance costs held to a minimum. This keeps customers coming back. If duplicate molds or components are to be built, accurate mold history will help designers and builders improve their designs and construction methods. Mold evolution should be based on performance evaluations and maintenance requirements as much as on new technological wizardry.

Mold layout sheets

We will start with the example of a 32-cavity, hot-runner cap mold (2004 Quarter Cap) that has been set in the press and is waiting to be fired up. First of all, you need to have a setup checklist to ensure that all steps necessary to hang and water the mold are implemented correctly and consistently. While the mold is conditioned to operating temperature, the process technician runs through his setup sheet to verify that all mold parameters are set correctly. Then, out comes the first shot and the molding process begins. If all is well, and after the process has stabilized, a shot or sample part is checked and released by QA and the run/repair cycle is under way.

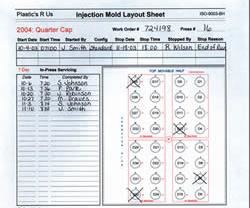

Now the process technician documents specific information on an injection mold layout (IML) sheet, such as press number, start date, start time, starting technician, and mold configuration. If the mold is hard to start or fill out, flashes easily, or suffers other issues, these observations are documented on the IML sheet for toolroom evaluations (see Data Flow Chart above).

The IML sheet is a critical element of the information chain. In sequential order, it documents mold, part, and other performance issues that may arise during a typical production run. This is important. When it comes to troubleshooting problems, the sequence of events can be an important clue in diagnosing the root cause and corrective measures to take. Whenever part of the run/repair cycle is not documented accurately, we can end up doing things twice, or worse. Generalized statements like “It never did that before” or “It always does that” need to be quantified to ensure we don’t waste time heading down the wrong path.

Reproduced here is an example of a completed IML sheet. All critical information for an effective repair has been documented. Defective cavities discovered by QA or processing personnel have been blocked off and noted. All that remains is for the last shot to be visually inspected for flash and other abnormalities. If quality issues are found, they will be noted in the repair plan. It is helpful to have a separate last-shot sheet for recording flash lengths that are close to being over spec and other visual observations.

A mold map and sign-off area for technicians performing in-press servicing are included on the IML. The frequency and depth of in-press cleaning depends on mold and process characteristics that determine residual contamination levels. It should be the goal of every shop to set standards for frequency of in-press and out-of-press cleaning, based on the amount of internal and external residue or contamination a mold exhibits after a certain number of cycles or hours run. This is the crux of preventative maintenance.

When the decision is made to pull the mold, a last shot of all remaining parts should be gathered for inspection, along with samples from any blocked-off cavities, and both should be forwarded to the toolroom supervisor. He will then decide whether to fix it now or wait until later and just monitor the mold during the next run. This is how we learn to better forecast tooling wear. Does it take another 10,000 cycles for the flash to grow over-spec, or does it happen after only 100 cycles? And if it grows over-spec quickly, is that because the process changed? Accurate forecasting of tool wear requires consistency in repair and processing.

IML data entry

Some companies have the luxury of entering data through PCs located at each press, but the vast majority of companies only have a PC in the molding office or at a staging area on the molding floor. This means that when something happens during a run, the processing technician needs to walk some distance to enter critical data into the PC. This probably won’t happen, because the technician can be hit with a dozen other issues during the 50-foot walk to the PC, so it gets forgotten, and the information never reaches the toolroom. Collecting IML-type data manually through a sheet that hangs at the press is more convenient and readily accepted by most process and maintenance personnel.

If your typical production runs are short and there are no issues to worry about, this mold-run data still needs to be documented to provide an accurate sequential history. When molds are run, pulled, green-tagged (okay to run again), and racked without any data being collected, you leave voids in the process history. That complicates everything from troubleshooting defects to tracking which lots or parts the mold ran during a given time frame.

The most difficult part of collecting performance data at the press is acquiring the discipline to use and manage an IML sheet. The toolroom supervisor must work with the molding supervisor to systemize the approach and share the IML responsibility. Repair technicians must know how a mold performs before corrective actions can be implemented effectively.

In the next installment, we will discuss using the IML sheet to create an accurate, effective repair plan.

Steven Johnson worked as a toolmaker for 26 years, rebuilding and repairing multicavity molds for Calmar Inc. and then as mold-maintenance engineer for Hospira Inc., a medical device manufacturer. Today, he is the maintenance systems manager for Progressive Components and has his own business, MoldTrax in Ashland, Ohio, which designs and sells software for managing mold maintenance (www.moldtrax.com). He can be reached at steve@moldtrax.com or (419) 289-0281.

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More