Custom Molding Levels Off

Exclusive Semi-Annual Survey in Cooperation with Townsend Solutions.

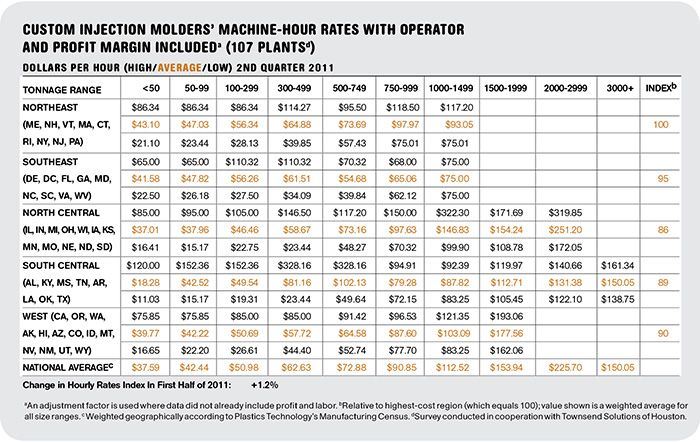

Our midyear survey of custom injection molders showed hourly rates still rising, despite a leveling off of the recovery.

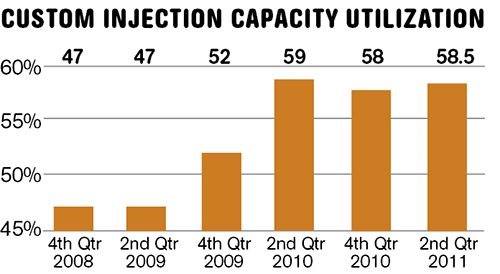

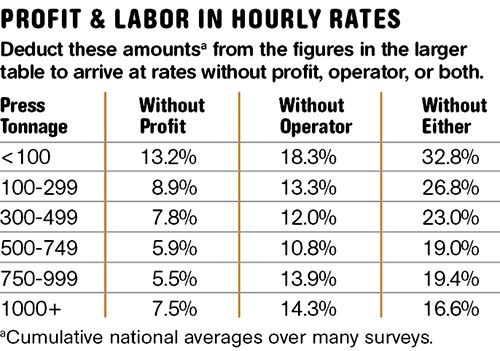

Our midyear survey of custom injection molders showed hourly rates still rising, despite a leveling off of the recovery. Responses from 107 plants showed average machine-capacity utilization at 58.5%, just half a point higher than at the end of 2010 (reported in May). Still, 52% of molders reported higher capacity utilization in the first half of 2011, more than twice as many as in the second half of 2010. Also, 20% saw lower utilization and 28% reported no change.

Our custom machine-hour rates index rose (see chart) for the third six-month period in a row. Almost 20% of respondents raised rates, while 2% lowered them and 79% made no change. Optimism showed a significant drop in the first half to its lowest level since mid-2009. Only 49% of molders said they saw improving business conditions in the near term, down from more than 60% for the last three six-month surveys. Almost 17% of respondents saw worsening conditions ahead, up from 8% at the end of last year, and 3% foresaw no change.

One bullish indicator was a 5.3% increase in new mold orders reported by 132 tool shops for the second quarter, six times higher than for the last quarter of 2010.

Related Content

-

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.