Direct Solar Heating for Rotational Molding Enables Feedback Control and Rapid Deployment

Light Manufacturing offers rotomolding factory in a box, with no utilities needed.

Karl von Kries began his career as a staff engineer at Hardigg Industries, a Massachusetts manufacturer of protective cases. It was a good place to learn rotomolding, but von Kries saw one problem. In the summer, as the sun beat down on the roof of the building, the air conditioning struggled to keep the temperature inside comfortable. At the same time, the facility was burning natural gas to heat the ovens it used for rotational molding. There had to be a better way. Years later, von Kries found one.

Heating the molds directly using reflected sunlight seemed an unlikely solution at first. Surely, someone somewhere had tried this and failed. But after a literature search came up empty, von Kries started a new company, Light Manufacturing, to explore the idea, experimenting with molds that had been painted black, a two-axis molding machine and a heliostat, which is a mechanism that automatically moves a mirror to track the sun’s path. The initial system did not make good parts, but it showed that the concept was feasible.

Several iterations later, the company is now offering solar rotational molding (SRM) systems that can operate without the utilities or infrastructure needed for a conventional manufacturing operation. Molds are heated directly by a array of heliostats that deflect energy from the sun, using the same principle as concentrated solar power generation plants. Electricity to power the motors, control computers and heliostats comes from photovoltaic panels.

The system can ship in 2 or 3 standard shipping containers, depending on the model, that include the rotomolding machines, photovoltaics, heliostats and batteries. The containers themselves double as enclosures for the molding chamber and operator’s cabin. The system can be set up on bare ground, in about two weeks, anywhere that gets sufficient sun. According to the company, this includes nearly half of the world’s land area. If a location turns out to be suboptimal, the system can be packed up again and moved.

LM’s rotational molding systems can be set up in two weeks with no need to connect to utilities. Electricity is provided by photovoltaics mounted on the container roof, while heat is provided by the array of heliostats at right. Source: Light Manufacturing.

The ease of deployment could make SRM the obvious choice for extreme locations with ample sunlight and scarce utilities. And it could be used that way, but the low startup cost, advanced controls and sustainability could appeal to a broader market.

Direct Heating Saves Energy and Enables Closed-Loop Controls

Conventional turret or shuttle rotomolding machines heat the mold in an oven, requiring air temperatures of 500-600°F to get the mold and the plastic inside up to the required temperatures in a reasonable amount of time. To establish process parameters like cycle time, a shielded and cooled box is built into the arm of the machine, and electronics are placed inside and connected to thermocouples that make measurements of the mold temperature.

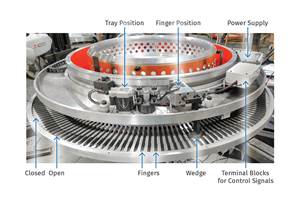

Because solar rotational molding reflects radiation from the sun directly onto the outer surface of the mold, most of the heat is directed just where it is needed. “What’s crazy is that you can actually stand in the chamber while 100,000 watts of heat are being pumped into that mold, two feet away and the air is maybe 120(°F),” von Kries says. “That means we can have advanced electronics and robotic components right there in the chamber, and they’re fine.”

A solar rotational molding system with a sample rain catchment tank. Source: Light Manufacturing.

Light Manufacturing has taken full advantage of this, implementing feedback control with real-time temperature monitoring. The temperature data is looped back to the control systems, adjusting processing parameters on the fly and ending the cycle exactly when the plastic has cured. A part run in the morning, or on a day with more clouds, may require a longer cycle or more mirrors focused on the mold.

The design of the part may need more heat on one side, if the wall thickness needs to vary. No problem. The system can adjust the speed of the motors to leave that side of the mold in the target area for more time. “The recipe for the part, and the target temperatures, are built into the brain of the system,” von Kries explains. At the appropriate time, the system goes into cooling mode automatically, the fans are activated and when cooling is complete a tone alerts the operator that they can begin demolding and refilling.

Sound Economics Complement Environmental Sustainability

Since 2016, Light Manufacturing has been making rotomolded components for Technomad, an outdoor audio systems manufacturer also founded by von Kries. It has also been supplying parts to other customers on a contract basis.

Light Manufacturing has three models of various capacities, with the largest capable of molding an 8,000-liter tank. According to von Kries, the system is now “ready for prime time” and the company is exploring partnerships with manufacturers who would purchase or license the technology.

The economics of such a system should be attractive. Energy costs for rotomolding can be 15-30% of operational expenses, positioning Light Manufacturing’s technology for significant potential savings. Energy cost could even be effectively negative in jurisdictions that tax carbon emissions or otherwise incentivize low carbon manufacturing. The option to skip the normal infrastructure would also tilt the economics in solar’s favor in some situations.

“It’s been an exciting journey to go from expecting it to fail to building this advanced machine. We’re excited to see where it’s going to go next,” von Kries says.

Related Content

Extrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More