Disk Pump Helps Compound Long-Fiber Thermoplastics

Already a familiar sight on European store shelves, the eye-catching appeal of "IML" is gaining traction among North American injection molders. The latest tooling and automation designs can handle the higher volumes needed here.

The goal in processing long-fiber thermoplastics is to keep the glass fibers as long as possible. A new pumping device is said to achieve this by wetting out continuous fibers with premelted resin, cutting them to a specific length, and then feeding them back into the downstream section of a single- or twin-screw extruder. Here are more details on this device, first described in our January report on the K 2007 show.

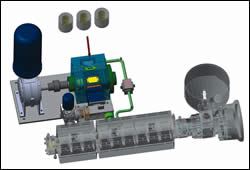

The rotary-channel pump is being developed by RCT Srl in Italy in cooperation with Italian extruder maker Amut. The pump can operate as a side-stream device, taking melt from the extruder upstream and returning wetted, chopped glass into the same extruder downstream. Alternatively, the pump could be situated between two separate extruders—one upstream for resin melting and the other downstream to disperse fibers before pelletizing or shape extrusion.

The Nexxus Channel F (fiber) pump was invented by Dr. Giuseppe Ponzielli, president and owner of RCT, to make thermoplastic composites with up to 60% glass. More important, the Nexxus pump can process continuous fiber to any length, according to Piergianni Milani, Amut’s v.p. of operations. “With Nexxus we can use longer fiber and so reduce the fiber content and raw-material cost, and get the same excellent mechanical properties as compounds with much higher glass content or thicker glass fiber,” he adds.

Another reportedly unique advantage is that the Nexxus pump can wet out glass fibers with even very-high-viscosity resins, down to fractional melt indexes of 0.2 MFI. “All other known systems to disperse endless fibers in an extruder are strictly limited to high-MFI materials—at least 30 MFI,” Ponzielli notes.

HOW IT WORKS

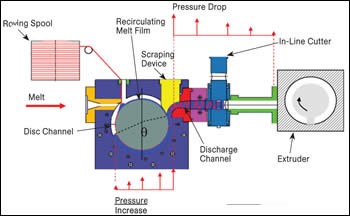

The Nexxus pump uses two or more narrowly spaced discs with a straight-sided groove or channel in the rim like discs in a pulley. Melt and continuous fiber enter this channel simultaneously, then travel around an arc as the disc turns inside a tight-fitting cylindrical housing.

A thin film of melt coats the channel all the way around the disc. Fibers are pulled into the melt coating under tension from drag flow as the discs turn. Tension spreads the fiber bundle into a flat tape at the bottom of the channel, wetting fibers out rapidly and evenly, says Dr. Ponzielli.

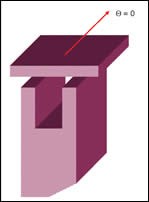

The square or C-shaped channel is enclosed in a heated casing, comparable to an extruder barrel. The difference is that the pump channels align melt flow at a 0° angle to the channel walls and casing, so melt infiltrates the fibers evenly. There is no forward motion along the axis of rotation, as there is in an extruder screw. “This makes it impossible to wet fibers in an extruder without breaking them as they pass through the flights,” Ponzielli says.

The melt and fiber are scraped out of the disc channel of the pump with a wedge on the opposite side from where they enter. Melt and fiber are then pushed by the wedge into a discharge channel. The current prototype of the disc pump has a discharge channel that widens out so that the liquid slows down, causing the uncut fibers to bunch up like an accordion. This may result in longer cut fibers after the roving passes the internal cutter, which can cut at preset intervals.

Besides glass, the cutter can handle nylon, PET, carbon, aramid, and natural fibers like jute and hemp. “Nexxus is the only impregnating device able to handle hard-to-cut fibers and hybrid fiber bundles,” Ponzielli claims.

‘NEEDLING’ ELEMENTS

The long-fiber compound then flows back into the main single- or twin-screw extruder. Ponzielli also developed a “needling system” for gentle dispersion of fibers during the final extrusion step. This system uses inter-raking needle-shaped elements to separate the fibers inside the extruder. In a single-screw extruder, the splined needling element fits on the end of the screw inside a barrel extension with internal pins to counter-rake the needles on the screw. In a corotating twin-screw extruder, intermeshing “needling” elements in a mid-section of the screw counter-rake each other.

RCT’s research prototype pump has three disc channels, each capable of pumping about 44 lb/hr. For higher throughputs, Ponzielli plans to add more discs of the same diameter. For example, 24 discs could put out 1056 lb/hr.

EARLY DATA

Amut and RCT have been experimenting together with long-glass extrusion on single-screws since 1999. They built the first precursor to the Nexxus pump in 2002 for an 1100-lb/hr profile line, installed at Uniq Extrusions in the U.K. to make scaffolding boards of PP with 35% glass (see photo). That rotary-channel pump was designed to wet out and disperse chopped-glass fibers, not continuous rovings like the current Nexxus pump. The pump for Uniq Extrusions was installed in a cascade between two extruders—a corotating twin-screw for initial plasticating and a single-screw for degassing and pumping. The advantage of the cascade is that processing parameters of the two extruders can be adjusted independently, Ponzielli says.

Continuous-fiber compounding trials with the Nexxus pump so far have focused on direct extrusion of glass-reinforced pipe, sheet, and long-fiber pellets using PP, HDPE, LDPE, and ABS with loadings of up to 60% glass.

The Nexxus pump setup in Amut’s lab has a single-screw extruder with 48-mm diam. and 35:1 L/D. The pump is installed at about 12 D, and fiber-filled melt re-enters the extruder 2D further down. Amut and RCT have extruded PP with 30% to 60% glass and found “excellent” mechanical properties (see table), reports Ponzielli. In its own lab, RCT installed the Nexxus pump in bypass mode on a corotating twin-screw extruder, a 60-mm Comac model.

RCT believes that the Nexxus pump could also be used inline to feed an injection molding machine with longer fibers than are currently possible (see Learn More). This application is under development.

| Glass-Filled PPa plaques (4 mm) Made with Nexxus Pump | ||||

| Glass, % | Tens. Mod., Mpsi | Tens. Str., psi | Elong., % | Ave. Fiber Length, mm |

| 30 | 1.16 | 14,500 | >5 | > 20 |

| 40 | 1.45 | 17,400 | >5 | > 15 |

| 50 | 1.74 | 20,300 | >5 | > 10 |

| 60 | 2.32 | 21,750 | >3 | > 5 |

| aBasell F30G, 12 MFI. | ||||

Related Content

Why Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreRead Next

K 2007 Compounding: New Approaches to Mixing, Pelletizing

In addition to the news reported in our September K Show preview (see Learn More), previously unrevealed developments in Dusseldorf include several ingenious devices designed to save energy, reduce wear, and safeguard compounded material properties.

Read MoreInjection Molding Compounders Molders Get Control Of Their Materials

The combination of an injection molding press and a twin-screw compounding extruder represents a new paradigm for processors: They create their own materials as they mold them.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More