E-Collaboration Is Coming (But More Slowly Than Expected)

Use of internet e-collaboration in plastics remains very small-scale, but big auto-parts suppliers are giving it a push.

Internet-based “e-collaboration” was supposed to provide seamless integration of all the elements of part design as well as faster part appro vals—not to mention big savings in company travel budgets. But most initial attempts to get plastics processors to use e-collaboration didn’t catch on.

Nonetheless, interviews with processors indicate that they would have an appetite for e-collaboration—if some hurdles could be overcome. For one thing, full-function collaboration software is expensive. “We had a vendor in here last week with a promising software tool that cost $200,000,” says Doug Wilson, technology development leader at the technical center of Johnson Controls Industrial Design in Holland, Mich. Annual maintenance cost for such software is typically about 20% of the initial purchase price.

The cost hurdle appears to be diminishing. First, prices of some e-collaboration services are coming down. Second, some large automotive Tier 1 and Tier 2 molders are finding less expensive solutions by picking and choosing just the functions they want.

What it does

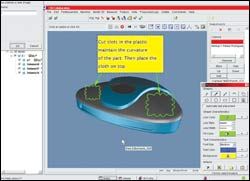

E-collaboration software lets users visualize, manipulate, and share CAD files and documents for group viewing and feedback. Packages offer a menu of functions that include CAD model viewing, document management, notification of engineering changes, workflow and status reports, and price quotes.

Software costs vary widely, depending on how many “seats” and how many functions a buyer takes. Some products are even priced according to who uses the seat. The same identical seat of PTC’s Windchill, for example, costs $1200 for a heavy engineering user, $400 for a light user within the same company—like someone in marketing or sales—and $600 for an outside supplier (plus 18% annual maintenance).

Many e-collaboration software providers belong to big CAD/CAM vendors, so their software is “native” to their own design system. They may require users to buy interfaces to non-native CAD platforms. That’s another way costs can mount up.

For example, EDS in Plano, Texas, offers the Teamcenter PLM (product lifecycle management) software tools for e-collaboration as well as Unigraphics NX and I-DEAS CAD products. Customers say EDS charges for interfaces even to its own e-collaboration software—and fees can run from $5000 to $50,000 for links to non-EDS CAD systems, depending on the number of seats and complexity of the installation.

Other CAD software providers that also offer e-collaboration products include Dassault Systemes’ Enovia subsidiary, Cimatron, Co Create, and PTC. E-collaboration software is also available from a number of independent firms such as Fullscope, Impact Xoft, and Matrix One.

Many e-collaboration tools create a simplified visual representation of the CAD model that can be viewed with just a web browser on a desktop PC. This permits simultaneous remote viewing by numerous parties without worrying about CAD compatibility—or even whether each person has a CAD workstation. A function known as “streaming” lets the leader of the online conference rotate and manipulate the actual CAD model, while the same movements appear on each remote screen. All this happens without transmitting the whole cumbersome CAD file. Remote images can be viewed passively, or another member of the group can be empowered to modify the model while the rest watch and discuss. Streaming can also be used to share Microsoft PowerPoint presentations with remote spectators.

Some designers warn that e-collaboration shouldn’t be oversold as a substitute for face-to-face meetings on critical issues. Nor is it practical to try to conduct an online group discussion among 20 or 30 people. “If you have a very controversial issue like product safety that requires negotiation, it should be taken off-line,” advises David Dean, president of Pursuit Engineering LLC in Detroit, an independent provider of automotive design and engineering services. “You don’t want to fight in public over the internet. You want to work out a solution first and then communicate it over the Web.”

Dean actually sees a reverse trend among auto makers and their suppliers. “I believe OEMs and Tier 1 and 2 suppliers are requiring more local support and face-to-face meetings, not less. Still, e-collaboration software is a great tool to educate and inform a large group,” he adds.

It can certainly save a lot of memo writing and phone calls to flag an engineering change for comments and approvals by a large number of people. E-collaboration also allows cost savings through international outsourcing of some engineering functions—like finite-element analysis of a part design in India or moldmaking in Taiwan.

E-collaboration can also sometimes supply a last-minute fix. In early 2000, U.S. Farathane Corp., a Tier 1 automotive supplier in Sterling Heights, Mich., had to accommodate a very late engineering change in an extruded PP profile for Ford. It would have resulted in an extra manufacturing step and added cost on each part. Instead, working with Ford via the Metaphase e-collaboration tool (now part of EDS’s Teamcenter Solution), Farathane’s supplier of downstream tooling was able to modify a secondary operation on the profiles to add the new feature at no extra cost per part.

Resin makers’ lessons

When e-collaboration software began to appear in the mid-to-late 1990s, two engineering-resin producers sponsored early efforts to use the technology to help customers design parts with their resins. But both firms have since stopped hosting outside e-collaboration software, largely because it wasn’t being used.

Ticona in Summit, N.J., invested in Conferos, a software company that had developed a tool just for plastics processors that was powered by Windchill e-collaboration software from PTC. Conferos closed its doors last year, and Ticona no longer offers its software to customers.

Ticona had no users for Conferos’s service but does make “e-rooms” available to customers for free on its website, using a custom collaboration program. Ticona is preparing to add web conferencing tools to complement its e-rooms. TI Group used the e-rooms to develop a fuel-pump system, but ultimately chose a different e-collaboration vendor that also supplied the CAD systems used within the company.

GE Plastics in Pittsfield, Mass., sponsored a similar e-collaboration site for a year and a half. The site used OneSpace collaboration software from CoCreate. GE closed the online Design Center (for which customers had to pay a fee) when it did not attract much use. One customer that did like OneSpace is Carlisle Engineered Products in Livonia, Mich., a Tier 1 auto supplier. GE switched Carlisle over to an internal GE Plastics online system called Quick Place for storing documents, “It’s not as sophisticated as OneSpace, but it works well,” a Carlisle source says.

The Big Three Detroit auto makers sponsored an e-collaboration effort that turned out to be costly and controversial. Their e-commerce venture, Covisint in Southfield, Mich., sells software called the Virtual Project Workspace, powered by MatrixOne. When car makers originally announced Covisint two years ago, it was intended to provide a way for car companies to get competitive bids from vendors. It was also supposed to provide a collaborative design environment for auto makers and their suppliers. But Covisint never upgraded the initial CAD visualization module, which presented only a static image that couldn’t be rotated or manipulated. In the view of many users, that left Covisint useful only for job quoting.

Covisint has sold 76,000 “seats” to 14,000 users because the auto makers require suppliers to have them. That has stirred a lot of resentment. “They make us pay every year to support the seats, and all it does is benefit them,” complains one user. The cost of a seat ranges from $50 to $250/month. “It makes it easier for OEMs to squeeze us on quotes,” says the technical director of a large Tier 1 and 2 supplier. “But the biggest issue is that our customers force us to pay for the seat and support fee, and then often the customer doesn’t even make use of it. Half the time they communicate with us by fax!”

A-la-carte for less

Several global Tier 1 and Tier 2 automotive molders are finding a way around the high inital cost and complexity of e-collaboration software. They are beginning to set up pilot installations consisting of selective collaboration features instead of more expensive full-function seats.

Nypro Inc. in Clinton, Mass., a custom injection molder with more than 40 plants globally and an increasing amount of automotive molding, started a pilot program at its headquarters three months ago. Nypro is installing a subset of PTC’s Windchill Solution, called ProjectLink. Nypro chose Windchill because it allowed the firm to select from a menu of functions rather than purchase an all-in-one package.

Nypro v.p. of engineering Richard Hoeske says his firm plans to install a limited number of seats to permit interactive review of product and tool design and to implement online document management for program development. “We want to be able to send a memo with 3D visualization when a change is made, with a box at the bottom for the recipient to approve the change,” says Robert Sheehy, manager of CAD design.

TI Automotive Systems in Warren, Mich., just signed up for its first in-house e-collaboration system using EDS’s PLM Solutions. “We wanted to translate bulky CAD drawings into a lightweight format, store them centrally, and allow people to share and view them cost-effectively,” says TI’s business systems manager. TI also wanted e-conferencing whereby a large, geographically scattered group could share the same image on-screen. TI will try to keep costs down by taking only a few high-level seats, several mid-level seats, and a large number of low-level seats. “At the plant level we want assembly engineers, who have very little CAD training, to be able to open a CAD model, look at it, take measurements from it, check clearances, look at an assembly structure and the order in which things are put together, and suggest changes back to the design team,” explains the TI Group official.

Johnson Controls Automotive Interiors has 290 locations in 30 countries. A company jet makes three flights a day, just back and forth between headquarters in Plymouth, Mich., and the design tech center in Holland, Mich. “Employees who don’t like to fly drive the three hours each way for meetings. So we know all about losing time for meetings. We want a better way to work, but it has to be cost-effective,” says Doug Wilson at the tech center.

Working with NetMeeting, a Microsoft collaboration tool built into every Windows PC, Johnson Controls has developed an internal online meeting capability. NetMeeting allows CAD files to be shared so that remote computers can see what’s being manipulated on a host CAD screen. It also has the same approval functions as many of the big commercial programs, without any extra cost. Wilson acknowledges that there are fancier packages out there, “But you get NetMeeting for free. We use these tools quite regularly, but we use them on a shoestring. We don’t see any need to spend a fortune.”

Meanwhile, prices are coming down for commercial software. Instead of having to buy a package users can “rent” its capabilities at the suppliers’ low-cost hosted sites. EDS’s newly acquired PLM Solutions business offers hosted e-collaboration on its E-Vis.com web site for a monthly cost of just $90/user. CoCreate hosts a site called OneSpace Success based on its OneSpace Collaboration software. The site offers e-collaboration plus benchmarking capabilities and ROI documentation for a $10,000 initial fee and $5000/month for unlimited usage and an unlimited number of seats.

Peer-to-peer collaboration is included in the latest generation of PTC’s Pro/Engineer CAD system, called Pro/E Wildfire. The Wildfire upgrade just became available last month. PTC also supports a hosted version of ProjectLink, which can be used for a fee by any maintenance-paying Pro/E customer. The customer can invite anyone in the world to e-collaborate over this connection at no additional charge.

Read Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More