Energy Savings Pay Off Fast for Custom Profile Processor

More and more processors are looking an energy as a place to cut costs and improve their competitive position.

There’s big money in kilowatts, as more and more processors are looking carefully at the amount of “juice” they use as an opportunity to rein in costs. Custom PVC extruder Intek Plastics Inc., in Hastings, Minn., began an energy-reduction initiative about a year ago, and slashed its energy bill 17% in the first year alone. And on top of that, the processor greened things up even further by implementing new production practices that cut its scrap rate by 24% and completely eliminated landfilling.

Intek is a privately held company that engineers and fabricates custom vinyl extrusions for medium to large OEMs in a wide range of industries, including construction, agriculture, recreation, appliances, telecommunications, windows and doors, commercial refrigeration, and LED lighting.

Its energy-savings program, dubbed JEEP (Joint Energy Efficiency Plan), is a four-year project developed in cooperation with Xcel Energy, its utilities supplier. The processor’s goal is a reduction of 25%, or 1.5 million kwh, by 2014. In 2010 alone, Intek realized about two-thirds of its overall goal, or a decrease of over 1 million kwh.

“We’ve very intentionally and aggressively modified processes and equipment to substantially reduce our energy use,” notes Mike Kinning, president of Intek. “Our energy steering committee has done a phenomenal job identifying the areas and equipment where the biggest reductions were possible and tackled those projects first. We’re seeing big payoffs already.”

Intek’s 125,000 ft² plant in Hastings houses more than 20 extrusion lines and nearly 200 employees. In late 2008, Intek consolidated its two Hastings facilities into its current location. With all of the production in one facility, Intek management saw the need to reduce the company’s electrical consumption to create greater capacity to accommodate the projected growth of the company.

Working with Xcel, the company developed a plan and formalized its commitment to reduce energy use and costs by signing the JEEP agreement in December 2009. The JEEP project summary includes energy-efficient upgrades to the company’s compressed-air system, lighting, manufacturing equipment, and HVAC systems, providing estimated energy savings and completion dates for each.

“We’ve made significant progress on the projects detailed in the JEEP summary,” said Pete Barboni, Intek’s continuous-improvement manager and chairperson of the company’s energy steering committee. “Some of the projects were relatively easy to implement, others have required sizeable investments of time and financial resources. Our senior management, the steering committee, and other dedicated associates have made this initiative a top priority.”

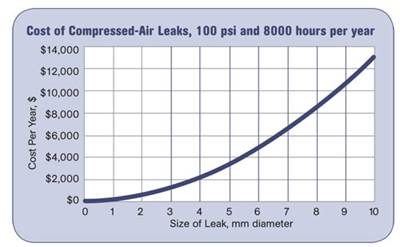

Intek’s energy consumption is monitored quarterly to determine the effectiveness of each implemented step in the JEEP plan. Most of the first year’s initiatives focused on improving the efficiency of the compressed-air system. After indentifying and eliminating air leaks, modifications were made to manufacturing equipment as well as reconfiguring existing air compressors to be able to reduce air pressure from 100 psi to 80 psi. As a result, the company has saved an estimated 628,430 kwh.

Further changes in manufacturing equipment and processes included upgrading to more efficient vacuum pumps; improving the chilled-water controls and shutdown process; reconfiguring the cleaning-oven cooling system; and switching to more efficient air nozzles and rings. These changes have resulted in a reduction of nearly 180,000 kwh.

Heating, ventilation, and air conditioning modifications, such as installing additional air-intake and exhaust fans, removing existing rooftop air-conditioning units, and eliminating localized space heaters, have netted the company a reduction of approximately 189,000 kwh.

Around the same time as JEEP, Intek launched a scrap-reduction program to improve material utilization and promote reclaiming and recycling of materials. This program involved several process changes to enable employees to reduce and reclaim scrap material.

Intek focused on reducing setup times between production runs and developed a waste-stream plan for every profile produced. Its scrap-collection and sorting process gives it the ability to reuse material rather than selling it or sending it to the landfill. As a result, Intek reduced landfill waste by more than 30% in 2010, and no longer landfills any PVC. The program rewards employees’ support and contributions by sharing 50% of the savings. In 2010, Intek’s employees each received over $1000 worth of scrap-reduction incentives.

Because Intek actively promotes use of recycled material in applications where virgin material may not be required, the company recycled nearly 1 million lb of plastic material internally in 2010 and purchased an additional million lb of recycled material from outside sources. In fact, roughly 15% to 20% of the total pounds Intek extruded was from recycled material.

Related Content

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreRead Next

Energy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More