Extrusion: Barrier Screws: Metering Section or Not?

A barrier screw without a metering section can reduce output and increase melt temperature.

A balanced design is required to get the best performance from a barrier screw. Barrier screws typically have three or four distinct sections that have somewhat different function, with each section balanced in relation to the others.

First is the solids-feeding section, followed by a compression or melting section, and then a metering section. The metering section is meant to stabilize the output and develop pressure to overcome the resistance of the die and downstream apparatus. Sometimes a fourth section (for mixing) is included in the design. Some barrier-screw designs have little or no metering section.

Instead, they are designed with a very long barrier section often followed by a mixer. That means the barrier section must assume the functions of the metering section as well. Using the barrier section to do this is inefficient if there is significant head pressure, particularly if processing a low-viscosity polymer. The barrier section is designed so that the melt passes over the barrier clearance and accumulates in a deep, narrow “melt channel.” The deep, narrow channel is necessary to meet the volume requirement to carry most if not all the melt forward, and the narrow width minimizes additional shear heating of the already melted polymer.

However, deep, narrow channels do not develop much pressure. In the event of substantial head pressure, these channels will have a large portion of backward flow (or pressure flow) that subtracts from the forward or drag flow, thereby reducing the net output. Moreover, the pressure flow results in repeated shear heating of the back-flowing polymer and an overall higher melt temperature. Of course, this won’t be a problem if there is a very low head pressure and/or if the extruder is equipped with a melt pump. Under those conditions, the requirement for pressure development in the metering section is largely eliminated, but stability may still be affected.

The accompanying illustration compares two barrier-screw designs that have identical dimensions except for the length of the barrier section. In a computer simulation, the screw with the longer barrier section (no metering section) has 9-10% less output at 100 rpm and 3500 psi head pressure with a 5 MFI PP copolymer.

The melt temperature is also higher; the backflow and the pressure stability exiting the screw has more variation because the discharge pressure from the solids and melt channels differ. The metering section provides a damping effect to stabilize any pressure variations coming from the barrier section. There can also be disadvantages in melting with too long a barrier section.

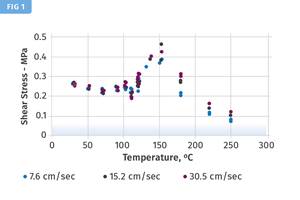

Any barrier-screw design—or any screw design for that matter—must be suited to the particular requirements of its application. One of those is the head pressure against which the screw will have to work. A barrier screw without any metering section compares well to one with a metering section at 500 psi head pressure, with the exception of stability. This will vary with melt temperature, polymer type and barrier screw design. I just did some extensive tests on a heavily-filled material and, when varying the head pressure with a valve, saw a drop in output of more than 15% at 3500 psi vs. a similar screw with an eight-turn metering section, which had only a 3-4% drop. If you use a melt pump, there is not much difference with or without metering, as the pressure is seldom above 1000 psi. But with this material, a melt pump was not an option.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years.He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreOptimizing Barrel Temperatures for Single-Screw Extruders

If barrel temperatures are set correctly and screw design is optimized, the extruder will be operating at peak performance, providing maximum profitability. If not, bad things can happen impacting quality and profitability.

Read MoreThe Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreUnderstanding the Incumbent Resin Effect

When you are looking to replace an existing resin with a new one, in trials sometimes the “incumbent” resin will cause gels and other defects. Here’s what to look for.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More

.jpg;width=70;height=70;mode=crop)