Extrusion: Head Pressure and Output Stability

Use drag- and pressure-flow equations to analyze fluctuating output.

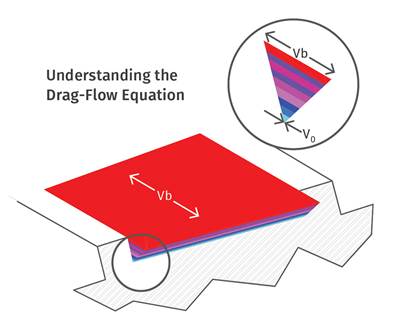

In my June and July columns, I discussed how to use drag-flow and pressure-flow equations to analyze the performance of an extruder. Those same equations can be used to analyze certain output stability problems. If the output has a rhythmic surge, the cause is almost always a partially filled metering section. A specific length of fill in the metering section is required to provide stability. That length depends on the polymer viscosity, screw design and the head pressure.

The mechanism of such a surge is an almost perfect cyclic response between the head pressure and the length of fill in the metering section. A partially filled metering section fills backward until it can balance the head pressure. When that occurs, the drag flow minus the pressure flow equals the actual output. Remember that the pressure flow is proportional to both the length of the fill and the viscosity for any particular screw design. The cyclic surge then develops as the metering section back-fills to balance the head pressure; but because there is a delay between the equalization and the response, there is a slight change in output. This becomes a harmonic variation or cyclic Head Pressure and Output Stability pulse that will continue until something changes to provide more back-fill, which dampens the response.

Using the drag flow, pressure flow, and actual output, a measure of the metering-section fill can be obtained:

Fill Length = [QP/ (QD-QA)]L

Where:

QP = Pressure flow

QD = Drag flow

QA = Actual output

L = Length of metering section

The amount of fill necessary to prevent a cyclic surge of this type depends on the polymer viscosity, channel depth, and head pressure, so there is no fixed fill length to eliminate such a surge.

Pressure flow is proportional to both the length of the fill and the viscosity for any particular screw design.

However, two flights are certainly a minimum; and with lower viscosities and lower head pressures, that can be as many as four flights.

The cause of such a surge can be confirmed by simply changing the head pressure. Lowering the head pressure will result in an increase in the frequency and magnitude of the surge. Conversely, increasing the head pressure will result in lower frequency and magnitude.

With a melt pump, simply lowering and raising the suction pressure will give you an indication if a partially filled metering section is the problem, if the frequency and magnitude of the surge are affected as noted above. It takes the “fill length” calculation to estimate the actual degree of fill. Without a melt pump, you’ll need to change some part of the downstream polymer flow apparatus to create a change in head pressure.

If a screen changer is used, changing the screens can usually do the trick. You’ll often notice a screw pulse with clean screens that will slowly disappear as the screens plug and the head pressure rises. That can be seen even with a melt pump, as the extruder screw speed chases the back-pressure fluctuation. The output to the die is steady because of the melt pump, but the screw speed is changing constantly. Although this may not seem to be a problem, changes in screw speed also change melt temperature, which may affect the final product, particularly complex profiles and very tiny extrusions such as filaments.

The cyclic surge is very common in two-stage screws where the design was not specific to the head pressure. That’s often the case for a new application where the head pressure cannot be estimated. But rules of thumb—like sizing the second metering section 1.5 times the depth of the first metering section—can result in this type of problem. In single-stage screws, the cause of a partially filled metering section is usually inadequate feeding, either by design, or because the characteristics of the polymer have reduced the output such that the metering section is not filled.

If the output has a rhythmic surge, the cause is almost always a partially filled metering section.

Very recently I reviewed a smoothbore extruder running HMWPE that had a steady cyclic surge. The slippery nature of HMWPE often produces a less-than-anticipated feed rate, resulting in a partially filled metering section. The surge was eliminated by raising the head pressure by just a few hundred pounds with the screen changer.

A word to the wise: Be sure to stay well under the pump discharge pressure when trying to eliminate the cyclic surge with a melt pump by increasing the suction pressure. That will keep polymer flowing through the melt pump bearings for lubrication and prevent damage to the device.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreA Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreRead Next

Extrusion: A Simple Way to Evaluate Extruder Screws

While there’s lots of data that influences screw design, processors usually don’t have access to it. So instead, try calculating drag flow to see if your screw is working properly.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More

.jpg;width=70;height=70;mode=crop)