Extrusion: Reducing Energy, Part II: ‘Adiabatic’ Extrusion

The term adiabatic extrusion was very popular in the ’60s and ’70s, but has seemingly disappeared from the processing terminology of today.

The term adiabatic extrusion was very popular in the ’60s and ’70s, but has seemingly disappeared from the processing terminology of today. Adiabatic extrusion means to operate with no input or extraction of heat. The disappearance of the term is due in large extent to the use of improved screw designs and the popularity of melt pumps. Pumps make for a more homogenous and stable output and have greatly reduced the care originally required in setting the temperature profile. However, adiabatic extrusion is still an important concept and should be considered when optimizing every extruder temperature profile.

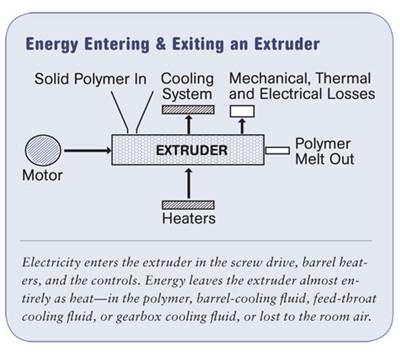

Last month’s article on extrusion energy savings (see Learn More below) illustrated the energy balance in an extrusion system. It indicated all the energy inflows and outflows. It doesn’t take much imagination to conclude that any changes in that balance would have the effect of unbalancing the whole system.

“Unbalance” means that there would be cycling of the heat flow, as heat zones continuously seek to reach a balance between their control setting and the temperature at which the extruder would settle without control. For single-screw extruders, the amount of energy entering through the screw drive greatly exceeds the energy input capacity of the barrel heaters, even if they were all on at full amperage all the time. In addition, the thermal conductivity of polymers is low, making it difficult to add or extract heat by conduction through the steel barrel wall. Conversion of screw power into heat by both friction and viscous dissipation is so much more efficient than barrel heating, since it all happens within the barrel.

Consequently, with the vast majority of the energy coming in through the screw, the barrel heaters become a regulating device that prevents or allows heat transfer through the barrel. As the zone temperature setting is raised, it reduces the energy exiting the system through the barrel, as heat flow is proportional to the temperature differential. As the setting is lowered. the exit of heat is enhanced due to the greater temperature differential.

Low control settings can work against the basic function of the extruder. In areas where the extruder needs to generate high levels of energy to melt the polymer, a low barrel-temperature setting serves to extract some of the melting energy being put in by the screw drive. Conversely, in areas where the polymer is melted, a high barrel setting forces more heat to stay in the melt. If the settings are far from where the system wants to operate, the system begins to cycle between heating and cooling. Zones set too high call for heat frequently, and in a fairly precise cycle. Zones set too low call for cooling frequently, and in a fairly precise cycle. When a number of zones are doing this, the heat flow in the whole extruder is in a constant state of flux.

All that cycling destabilizes the extruder output, as extruder feeding, melting, and pumping are closely tied to the temperature and/or viscosity of the polymer near the barrel wall. It also wastes considerable energy, as the system heats and cools unnecessarily to hold a temperature profile the extruder does not want to hold and generally does not need to function well.

A profile where very little heating or cooling occurs almost always provides the most stable output. Surprisingly, it usually produces the same or even lower melt temperature than with a lot of imposed cooling, which wastes a lot of energy.

Try starting your extruder with your normal profile; and then once it is relatively stable, tune your zones for adiabatic extrusion. Zones calling for heat frequently should be gradually lowered, and zones calling for cooling frequently should be gradually raised. Although complete stability of all the zones may never be reached on some extruders, see if this stabilizes your extruder without increasing melt temperature while providing considerable savings in overall power consumption. Even with a melt pump, this technique will stabilize die flow and reduce the screw-speed cycling due to changing viscosity.

Many operators ask, “What‘s the best temperature profile for my extruder?” About all that can be offered is a starting point, since every extruder runs a little differently. And as soon as there is any change in the screw speed, polymer, or head pressure, the optimum settings will change. Try the adiabatic approach to see if it improves your stability. I know it will improve your energy usage.

About the Author

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreThe Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Extrusion: Run Your Chevy Volt with Extruder Energy Savings—Part I

The electricity saved on a large extrusion line could power a number of Chevrolet Volts.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)