Five Factors to Consider When Molding PEEK

Are you a first-time molder of PEEK? Have you tried molding it and might be running into trouble? Take a look at five factors in the injection molding process that can help to avoid the need for troubleshooting when molding PEEK.

Are you a first-time molder of PEEK? Have you tried molding it and might be running into trouble? In this article we consider five factors in the injection molding process that can help to avoid the need for troubleshooting when molding PEEK polymer - and it can help to reach the full potential of this high performing polymer.

Equipment: Standard Injection Molding Machines

PEEK can be molded on standard injection molding machines supplied by most of the well-known machine suppliers. Depending on the grade of PEEK that you’ll be molding, processing temperatures on your injection molding barrel will be somewhere in the range of 350°C-400°C (662°F-752°F). These temperatures can be reached on most standard injection molders with cylinder heaters without the need for modifications. If modifications are required these are usually for the heater bands or thermocouples/controllers. We suggest you use ceramic heater bands as they provide the most consistent processing. Additionally, consider the use of barrel blankets as they provide heat insulation, with the benefit of energy cost savings. A general purpose screw is effective. Copper and copper alloys should be avoided (in contact with melt). All metallic components should be smooth and highly polished to prevent hang ups.

The Importance of Drying PEEK Polymer

PEEK pellets are supplied nominally dry but may absorb moisture from the atmosphere. In our literature, we provide some guidance on drying. In short, we suggest drying the pellets on trays in circulating ovens for 2-3 hours at 150°C-160°C (302°F-320°F) or, alternatively, overnight drying. The aim is/should be to reduce the residual moisture content to <0.02%. Dehumidifying or desiccant dryers may also be used and must be capable of maintaining a dew point or saturation temperature of - 40⁰C (- 40°F).

Cleanliness is Key

Any contamination should be avoided when processing PEEK. Most other polymers will degrade at PEEK’s processing temperatures and therefore it is imperative to start with clean drying ovens, hoppers, injection molders and any other containers used to hold runners or parts. Pull screws and properly clean and brush the barrel and screw before starting to mold PEEK. Check for hang ups in hoppers. Regrind can be a big source of contamination and we suggest that you use dedicated equipment for the regrinding of PEEK materials. Any contaminants during the injection molding process will show up as black specs in your final component.

Use the Biggest Gates Possible

PEEK likes big gates. Gate size is dependent on the part volume, number of cavities and component geometry. PEEK is a semi-crystalline polymer and exhibits much higher shrinkage compared to an amorphous thermoplastic. Moreover, cooling from a much higher processing temperature to ambient causes more shrinkage compared to lower temperature processing polymers. Using the biggest gates possible will enable that you fully pack out your component. At Victrex, we have a general rule called the 2/3rds rule of the maximum section thickness of your component. Depending on the grade of PEEK that you’ll be molding this might be a minimum of 1mm (0.04in) for unfilled PEEK and 2mm (0.08in) for compounds. Gate designs such as tab, side or fan gates are most commonly used. Submarine or tunnel gates can be considered for very thin walls or small parts but tend to lead to freeze off during molding of bigger parts.

Good Temperature Control

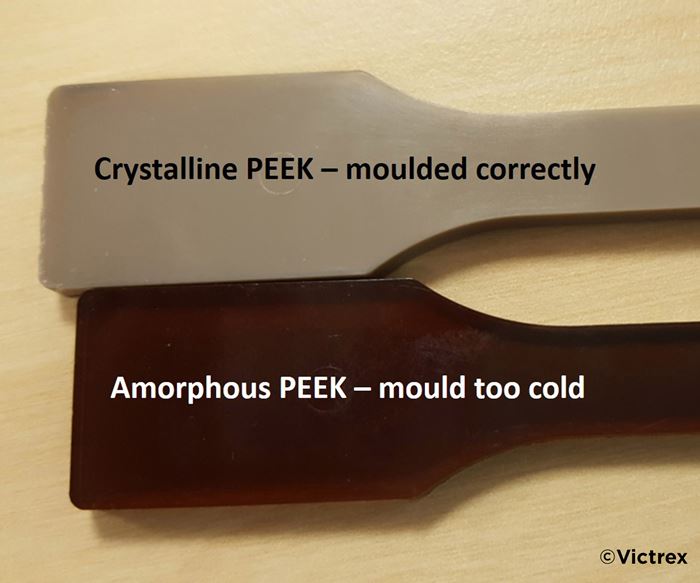

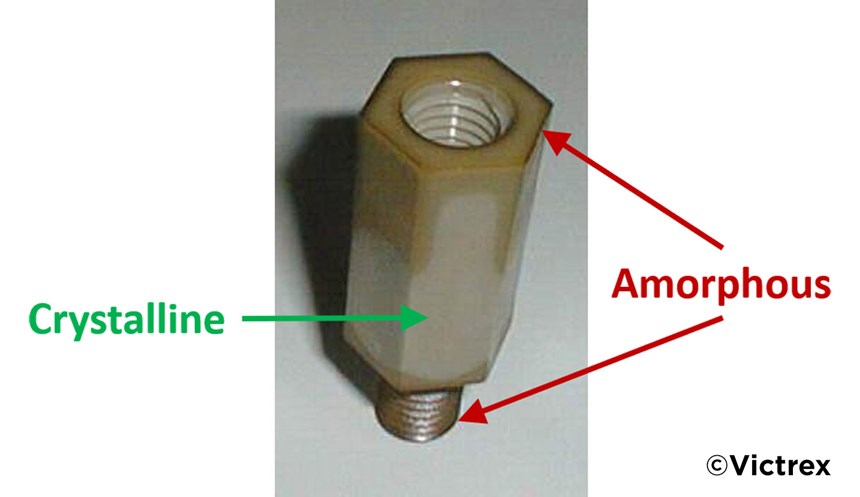

The mold temperature is critical to obtain a semi-crystalline component that can fully utilize PEEK’s unique set of properties. Let’s look at some components that are not molded correctly.

The brown sections are the amorphous PEEK and the beige colored sections are semi-crystalline PEEK. To mold PEEK and its compounds successfully one needs to be able to maintain mold temperatures between 170°C - 200°C (170°F - 392°F) - to avoid quench-cooling into the amorphous state - depending on the grade being molded. It is important to note that this should not only be the set temperature on the mold, but indeed the surface temperature on the mold. This can be achieved using electrical heaters for smaller parts and oil heaters with isolated flow lines for larger shot sizes or tools with large/deep cores. Consider using insulation boards between the mold and the machine platen as well as packing the tool with thermal insulation for uniform temperature distribution across the mold.

In summary, there are many other factors that play a role in successful PEEK molding, but the five outlined above, are a good introduction to what is important when starting to mold PEEK.

- Standard molding equipment can be used to mold PEEK.

- Dry your PEEK pellets well before starting your molding process.

- Keep the process clean - any contamination may cause problems during the molding process.

- Use big gates to properly fill your mold and pack out your component.

- Have good control over the mold temperature to ensure semi-crystalline PEEK components.

ABOUT THE AUTHOR: Carin Burger is a material scientist that has worked at Victrex for 14 years. She has experience in R&D and technical services and enjoys her work as part of the technical service team, working with customers to solve their issues and providing support in design, processing and manufacturing. Email: cburger@victrex.com; Phone: +(44) 1253 897700. Find out more at www.victrex.com.

Related Content

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MorePrices of Volume Resins Generally Flat or Lower

Exceptions in early March were PP and PS, which moved up solely due to feedstock constraints, along with slight upward movement in PVC and PET.

Read MorePrices Bottom Out for Volume Resins?

Flat-to-down trajectory underway for fourth quarter for commodity resins.

Read MoreThe Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More