Fixing Hot-Runner Filling Imbalances: Take a Systematic Approach

Jumping right in to try to make a fix without a methodical troubleshooting approach is apt to waste a lot of time and perhaps even make things worse. There is a better way.

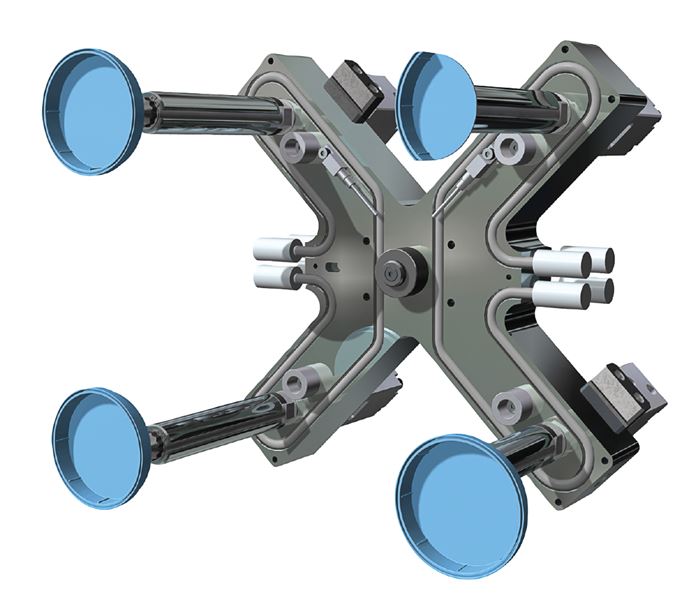

In order to have the largest potential process window when injection molding with multi-cavity tools, it’s important that all the cavities fill at the same time. Cavity-to-cavity and shot-to-shot variations will make it difficult to consistently mold flash-free, fully packed parts with uniform dimensions. Although hot runners can provide huge benefits to the molder, they do increase the complexity of the tool and add to the list of potential root causes of a filling imbalance.

Like all troubleshooting issues, it is important to have a systematic approach when hunting down the source of filling balance problems. Jumping to conclusions and making changes on assumptions can often make problems worse or, at the very least, extend the time and cost involved in resolving the issue. Taking a little extra time up front to properly identify the problem and to collect some basic data can greatly reduce the amount of time required to arrive at a root cause and remedy the issue.

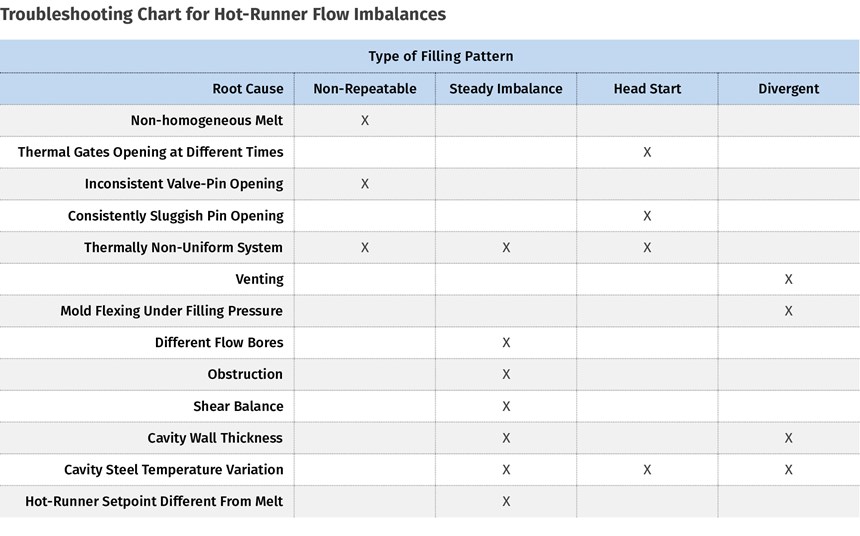

Typically, when a balance problem is identified it is defined and quantified by simply taking a short shot and comparing the resulting parts. Although this proves that the cavities are filling unevenly and gives a general sense of the magnitude of the filling imbalance, it does little to point us towards a root cause. Before wasting any time trying to correct a filling imbalance issue, two fundamental questions should first be answered:

1. Is the filling imbalance repeatable from shot to shot?

2. How does the filling imbalance develop?

In order to answer these questions, short shots need to be molded, but it is important that this is done properly. Any process adjustments that were made previously in an attempt to remedy the balance issue should be first returned to nominal values. The same injection speed profile used to mold the parts should also be used when taking the short shots. The tool is shorted by turning off pack and hold and adjusting the transfer position to a value where the fastest-filling cavity is approximately 90% full. Filling much beyond 90% will tend to allow the slower cavities to catch up, making the balance appear better than it actually is. Several short shots should be taken and weighed to determine the magnitude and consistency of the problem, allowing us to answer the first question: Is the filling imbalance repeatable from shot to shot?

WHEN FILLING BALANCE IS INCONSISTENT

Knowing that the filling balance between the cavities is changing from shot to shot either in a particular direction or significantly in magnitude helps us isolate potential root causes. When this situation is observed we should start by focusing on melt homogeneity and the consistency in which the hot-runner gates open.

Try to improve melt homogeneity by adjusting the barrel temperatures, backpressure, and screw speed. Always keep the hot runner at the same temperature as the melt, which should be confirmed by probing an air shot. Repeat the short-shot study to see if there is any change in consistency.

If improving melt homogeneity does not help matters, you should then focus on the consistency with which the hot-runner gates open. Hot-runner gates fall into two categories, thermal gates and valve gates. Thermal gates operate by allowing some material inside the gate to freeze and create a dam of frozen material while the part is cooling. When the mold opens, that frozen dam stays in the gate preventing molten plastic from drooling out of the gate. Injection pressure from the following cycle pushes the dam out of the gate, causing the gate to open again.

In order for a multi-drop, thermal-gated system to be balanced, all of the thermal gates need to open consistently at the same time. When thermal gates are too cold they can take excessive pressure to break open. Inevitably some gates open before the others, temporarily relieving the pressure behind the remaining gates, delaying them until sufficient pressure builds up behind them again. This problem can be created by running the hot-runner tips or the mold too cold, by excessive cooling in the gate area, unwanted contact between the hot runner and the tool, damaged or worn gate components, or temperature control-related issues.

Valve gates have a valve pin that retracts to open the gate at start of injection and closes at the end of pack and hold to seal the gate. These valve pins can be driven hydraulically, pneumatically, or electrically. Much like thermal gates, if the timing of the gate openings is not consistent from shot to shot ,an inconsistent balance situation will be created. All of the issues that could cause a thermal gate to operate inconsistently can cause a similar problem with a valve gate, but because we’re relying on the movement of the pin, there are some additional factors to consider: air in hydraulic lines, torn or worn actuator seals, mechanical issues such as a slightly bent pin, or contamination in the hydraulic or pneumatic supply lines.

Today, many valve-gated hot runners are available with actuator sensors that give either full position feedback or at least signals when the pin is full open and closed. This data is greatly beneficial when troubleshooting balance problems because it allows the molder to see directly how quickly and consistently the pins are moving, which is a difficult task otherwise. Adding a slight delay between when the pins open and when injection begins can also help identify when pin timing is the problem. If the delay improves the situation, then most likely the cause is that the pins are not all open when injection begins.

HOW DOES FILLING IMBALANCE DEVELOP?

If the imbalance is consistent, then understanding how the filling imbalance develops can give us further information about what the likely causes are. Consider the example of a two-cavity mold where a fully packed-out part weighs 100 g but when you short-shoot the tool you consistently get 90 g out of cavity one and 81 g out of cavity two. Understanding how those two cavities arrived at that 10% differential is valuable information that can be obtained very quickly by performing a short-shot progression.

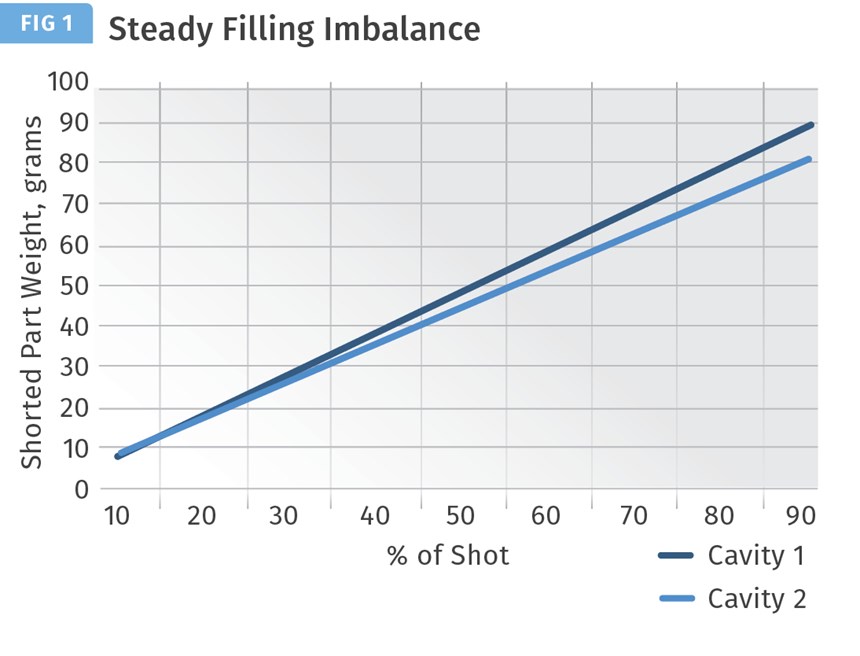

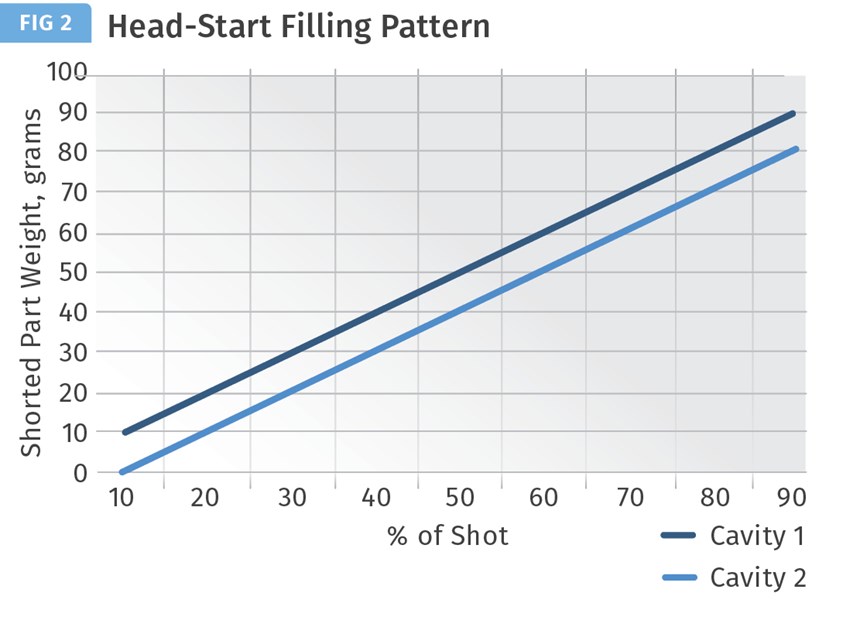

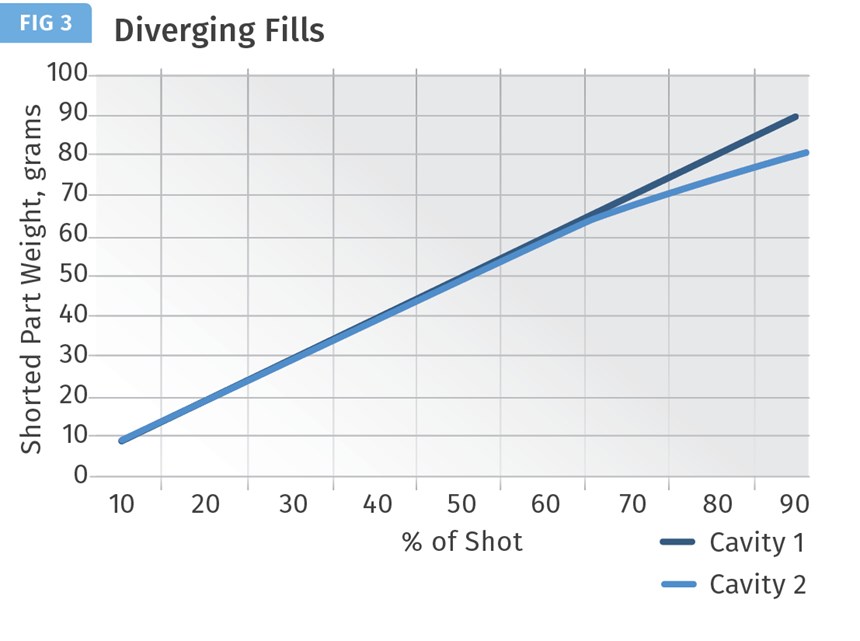

A short-shot progression is achieved by shorting the tool in the manner previously mentioned at 10% full, 20% full, etc., all way until the fastest-filling cavity is 90% full. When the parts are weighed and the weights are plotted for each cavity, you can see how the imbalance develops. The imbalance development typically falls into one of three different patterns, which can help point us to the root cause.

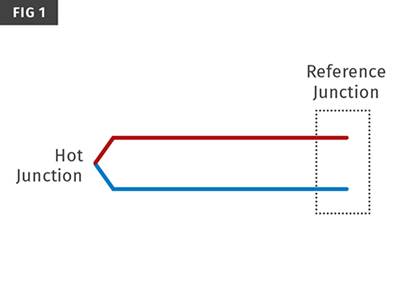

• FILLING PATTERN #1 – STEADY IMBALANCE (Fig. 1) With this filling pattern, you can see that both cavities begin filling at the same time, but cavity 1 is consistently filling at a faster rate, resulting in a 10% filling imbalance. When confronted with this filling pattern, you are searching for something that would be consistent throughout the filling of the part.

Common causes that fit into this category include cavity wall-stock thickness, cold-runner and gate dimensions, hot-runner flow-bore dimensions, differences in valve-pin stroke, contamination lodged in the hot-runner, and flow-path temperature variations either in the tool steel or hot runner. Shear-induced balance issues caused by the runner layout will often follow this pattern.

• FILLING PATTERN #2 – HEAD START (Fig. 2) In this case, we arrive at the same imbalance at our 90% short shot, but the fill pattern to get there is very different. Here cavity one starts filling before cavity two but once cavity two begins filling they fill at the same rate. This pattern indicates an influence that is present only at the beginning of injection, such as consistent differences in the opening of the gates.

• FILLING PATTERN #3 – DIVERGING FILLS (Fig. 3) In this last pattern, both cavities start filling at the same time and both fill at the same rate for the majority of the fill. It’s not until towards the end of the fill that they diverge, resulting in the 10% imbalance. In order for this type of pattern to develop, the influence on the fill pattern doesn’t occur until later in the fill. The obvious causes include changes to the cavity wall stock or temperature near the end of fill, but there are other potential causes as well. Poor venting in one cavity will have most impact as the flow front nears the end of the part. Also, when the cavities are nearly full, the force exerted on cavity steel from the plastic pressure can cause the cavity to deflect, temporarily increasing the wall stock in one cavity and therefore the flow to it.

This article is not meant to be an exhaustive summary of every potential cause for flow imbalances, but rather an explanation of how collecting and analyzing data in a methodical manner can help identify root causes and shorten the time necessary to resolve the issue.

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreRead Next

Reduce Hot-Runner Downtime With Proper Troubleshooting

Solve your problem faster by adopting a systematic approach. Here’s how to get going.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More