Flambeau Finds the Right Balance of Custom & Proprietary Molding

Flambeau Corp.'s most famous product is the Duncan yo-yo.

Flambeau Corp.'s most famous product is the Duncan yo-yo. The Baraboo, Wis., processor was the first to mold them out of plastic instead of wood back in the 1950s. Today, its Duncan Toys Div. still designs versions of the world's top-selling yo-yo that sell for $2 to $100. Along with duck decoys, floral containers, and tackle boxes, these proprietary products generate 30% of the company's $350 million annual revenue.

President Jason Sauey, whose father started the company, oversees eight plants—six in the U.S. plus one in England and one in Mexico. He has some 250 injection and blow molding presses to run at a profit while keeping around 1800 domestic workers gainfully employed. With 70% of revenue now coming from outside contract work, that is far from easy. "One has to do more than 'shoot and ship' to prosper in contract molding," he remarks. Flambeau today is a market-oriented product-development firm for which processing is a critical activity, but not its prime reason for existence.

Solution provider's creed

Since its start in 1947, Flambeau has focused on molding value-added products. Although always a contract molder, Flambeau puts considerable emphasis on proprietary products. "They are a blessing, since demand for them loads up our assets and gives us a way to track design, taste, and technology trends," Sauey says. Proprietary products often enjoy a degree of protection against lower-cost imports. At the same time, Flambeau's contract business emphasizes larger parts for auto interiors, ducts, and tanks, which enjoy "natural protection" against imports because of lower freight costs and faster deliveries.

Flambeau recently merged its formerly separate contract-manufacturing and proprietary-product companies into a single entity. This strategy is expected to foster more cross-fertilization of ideas between the multiple industries served.

Today, Flambeau's 140 injection presses of 24 to 1300 tons and 110 extrusion blow molders with up to 75-lb accumulator heads service customers in 40 industries from automotive and appliance to electronics and industrial packaging. Its mission is to bring to contract processing the same inventiveness, attention to detail, and full-service capability that Flambeau applies to proprietary products.

Flambeau's goal is to provide contract customers with full turnkey capabilities from tool design to molding to finishing. Its injection and blow molding machines typically coexist under one roof, says Marc Mason, v.p. of operations. Flambeau also offers hot staking, ultrasonic welding, and vacuum metalizing. In fact, the real drivers of revenue growth are secondary operations and engineering services, Sauey says. The Flambeau Technical Center develops fixtures and finishing systems. Its staff designs molds and prototypes, builds around 600 molds a year, and also subcontracts some tooling projects to a global network of moldmakers.

When it comes to trying out new technologies, Sauey prefers to be on the leading edge, not the "bleeding edge." If you overreach and try to be too innovative, you can go bankrupt, he warns. But he is not afraid to take risks. In blow molding, for example, Flambeau is one of a handful using 3D suction blow molding to make automotive ducts, and it has pioneered techniques to incorporate textiles into blow molded auto seating and floor panels. Flambeau also is unusual in applying in-mold labels to large blow molded storage boxes and stadium seats. The Fluids Handling Div. is working on better barrier designs for low-emissions fuel tanks on lawn/garden equipment, power tools, and other small engines. And its injection molding operations use advanced techniques like in-mold decorating, two-shot molding, and gas assist. Some presses have been adapted to run high-specific-gravity compounds incorporating up to 90% metal powder for molding fishing-line sinkers and munitions.

Related Content

Fakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreArburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

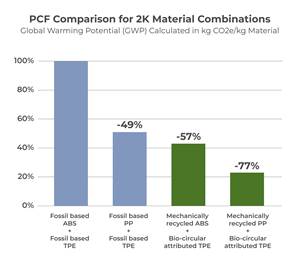

Read MoreMore Sustainable Two-Component Overmolding

Swedish compounders HEXPOL TPE AB and Polykemi AB have collaborated on a 2K sustainable development project for consumer products.

Read MoreMilacron’s Massive Booth Highlights Multiple Brands

NPE2024: Coinjection of postconsumer resin, in-mold decoration, LSR micromolding and bioplastics processing are just some of the machine displays at Milacron's booth.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More