Follow These Tips to Maximize Purging Efficiency

Commercial purging compounds offer dedicated solutions to your equipment cleaning needs, but some can be more effective in cleaning the ‘dead areas’ in certain screws and tooling. Follow these tips to choose the right one for your application, and make sure to follow the right protocol when shutting down for long periods.

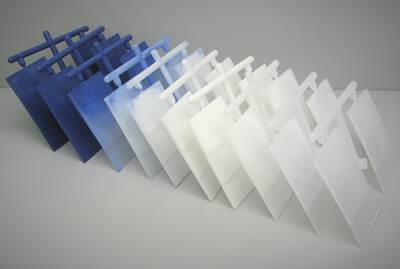

Using a commercial purging compound is recommended for cleaning out plastics machinery for shutdowns since it is more thermally stable and can take extreme heat variations. (Photos: iD Additives)

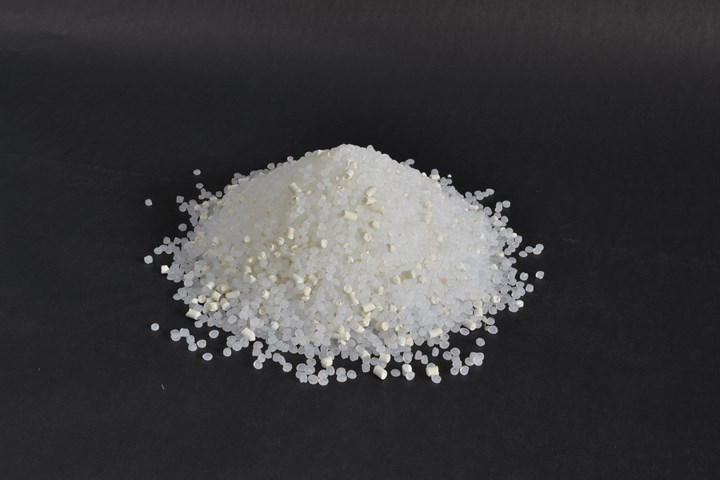

Commercial purging compounds (CPCs) have been shown to be the best way to clean resin out of your plastics processing machinery. And they are also the most effective way to purge processing machinery during extended shutdowns. Believe it or not, many processors continue to try to purge their machines with home remedies that include everything from wood chips to hand soap. Not only are such treatments time-consuming (due to the need to remove nozzles, dies etc.), they do nothing to clean internal machine components such as check rings.

Other processors run excessive pounds of virgin material through their machines to purge the previous material. This is both expensive and ineffective. Why add excess material or scrap parts to landfills? Color and material changes are faster using a CPC. Most CPCs are designed to remove stubborn carbon and color deposits, while ordinary processing resins fall short of the ingredients necessary to clean a barrel and screw.

The use of a proper purging compound can also prevent the need for screw pulls. And when screw pulls are required, purging compounds can significantly reduce the time and effort required for the procedure.

In order to choose the correct purging compound, you first must evaluate your process, which should start with the equipment and/or tooling and any limitations they may have. Just like tools in a toolbox, each type of purging compound has a function, and they are typically broken down into the following categories:

• Mechanical Purge: Cleans by scouring with a particulate such as glass or mineral.

• Chemical Purge: Cleans using chemical reaction.

• Hybrid Purge: Cleans using the components of both mechanical and chemical purge types.

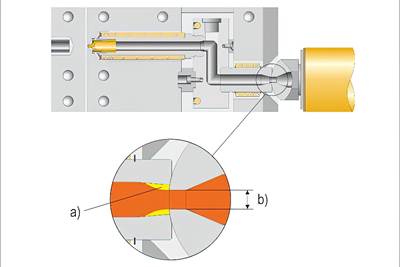

While mechanical purging compounds can be effective, they may contain particles that will lodge or block areas of the process such as small hot-runner tips or extruder screens. While a mechanical purging compound is often a great choice to clean the screw and barrel, a chemical-type purge, or even one that foams or expands, may prove more useful in cleaning the “dead areas” that are common in certain screws and tooling.

Maximize Purging Process Dynamics

Here are some steps that will ensure you maximize the dynamics of the purging process:

• Ensure that the barrel is fully charged.

• Run the screw speed in injection molding between 70 and 120 rpm once the purge starts to come out of the machine. Use short bursts throughout the process to clean the check ring and mixing nozzle.

• In extrusion, start rotating the screw slowly, and then vary the screw speed throughout the process.

• During the purge process, stop the screw and allow the purge to settle into any dead areas.

• For both injection molding and extrusion, make sure to purge at the temperature of the current material you are trying to remove.

• For best results, repeat the process when introducing the next production material.

By changing the screw speed and velocity of the material flow, you are providing a highly fluctuating environment of pressure and agitation that allows a purging compound to work at its best. This is done until the purge is visibly free from any contamination.

A periodic purging routine or preventive-maintenance purge program should be established to avoid contamination buildup.

As a best practice, a periodic purging routine or preventive-maintenance purge program should be established to avoid contamination buildup, which could lead to more difficult purging situations requiring greater time and effort. A preventive program is essential to any plastics-processing facility for the following reasons:

• Reduces scrap. (Each scrap part is a lost sale.)

• Increases machine utilization. (More business opportunities.)

• Reduces screw pulls by an average of 50% or greater.

• Typically decreases production downtime by an average of 65%.

• Typically reduces natural/virgin resin consumption for purging by an average of 45%.

• Typically increases production efficiencies by an average of 35%. (Operators spend more time making parts, not standing around.)

Purging for Extended Shutdowns

Because the use of normal resins results in oxidation over time, causing carbon contamination, it is not recommended to leave material in the machine barrel at shutdowns. Purging with a CPC is recommended for cleaning out machinery for shutdowns since it is more thermally stable and can take the extreme heat variations.

Implementing a preventive-maintenance purging program is essential to increasing efficiency and profitability in any plastics -rocessing facility.

After a thorough cleaning with a mechanical or hybrid purge, a “shutdown and barrel sealing” procedure is highly recommended for extended shutdowns, to minimize material oxidation or buildup of carbon, particularly with a non-glass-filled grade of purging compound.

Sealing the barrel ensures that no further oxidative degradation occurs and provides further cleaning. When to seal or not seal may depend on employee comfort and confidence level. You don’t want to damage machines at startup; if you rotate a screw that is not properly heat-soaked, you could possibly break a screw tip.

Implementing a preventive-maintenance purging program is essential to increasing efficiency and profitability in any plastics-processing facility. Whether experiencing black specks caused from resin degradation or color contamination from a previous production run, most part esthetic issues are related to the lack of a better purging program that includes the extended shutdown.

Purging with a CPC is recommended for cleaning out machinery for shutdowns.

Incorporating the proper CPC into a preventive-maintenance purging program can substantially reduce layers of carbon buildup, eliminate the potential of cross-contamination of resins and/or colors, and lessen the need for screw pulls.

The following preventive-maintenance purging program is recommended for injection, extrusion or blow molding processes and includes these four steps:

1. Purging the screw and barrel with a mechanical or hybrid purge compound. This first step removes the contamination and buildup on the screw and in the barrel. Tougher purging applications may require additional purging cycles.

2. Intermittent purging before, during and after production runs. This step varies depending upon the resin and colors being run. However, purging every two to three days with a chemical or hybrid CPC would be a good place to start. Evaluation will determine the optimal type of CPC and whether longer periods may be introduced.

3. Sealing the barrel with non-glass CPC for extended shutdowns is great for removing oxygen from the barrel (eliminating any oxidation), as well as preventing any carbon buildup that may be in the initial stages. Some people are not comfortable doing this, so leaving residual purge is fine. The important thing is to remove the previous material.

4. Purging the hot-runner/manifold system, die and accumulator head. After the screw and barrel have been systematically purged clean, the final stage is designed to ensure the mold and its components have been purged clean and are free of contamination. Raising the temperature may be necessary to help clean certain areas of these components.

Procedures for Shutdowns

Here are key purging procedures to follow for shutdowns:

Typically, there is no need to modify the RPM or temperature setting after thorough cleaning.

• Make certain that all auxiliary equipment is disconnected.

• Clean the hopper and feed throat.

• Clear the barrel by starving the screw, leaving the barrel free of resin.

• Introduce the proper CPC at a ratio of 100%. Typically, only one barrel capacity is required for a normal purge process; older equipment and more difficult purging applications may require an additional purge cycle.

• Load the CPC into the hopper or feed throat and charge the entire barrel.

• Purge continuously until the purge is clean and free of any contamination.

• During the process the CPC experiences a thermal mixing reaction that breaks down any color or degraded polymer in the barrel and on the screw.

• Although soaking is not required, it may be necessary for tough purging applications. In some cases, reducing the temperatures slightly and allowing the CPC to stand in the barrel will result in a more effective purge.

• Once the barrel is completely clean, charge the entire barrel with the CPC and stop screw rotation and turn off all heaters on the machine.

Caution: Do not rotate screw while the system is cooling down.

During startups, slowly rotate the screw once the operating temperature has been reached—do not rotate the screw at full speed.

Procedures for Startups

Here are key procedures to follow for startups:

• Turn machine power on and raise the operating temperature to 350-375 F.

• Do not rotate screw until heats are at operating temperature and proper heat soak is achieved.

• Follow any additional startup procedures necessary for the process.

• Once the operating temperature has been reached, slowly rotate the screw—do not rotate screw at full speed.

• If the purge coming out of the machine has any contamination, introduce more of the CPC and flush the system until thoroughly clean.

• Using the resin required for the next production run, flush out remaining purge.

• Ready the machine and begin production.

By following these procedures, you are now reassured that the machine is properly shut down for the weekend or holidays, and can be confident that when it starts up again, good parts will be produced. You will be thrilled to be up and running so quickly. With the proper recommendations and training from your CPC supplier, purging will no longer seem complicated. This knowledge and training in the proper method of shutting down will yield proven results in less time and processors will save money by having less scrap and wasted material to throw away.

What to Expect from Your CPC Supplier

Taking into consideration that no two CPC’s are alike, here’s what you ought to expect from your CPC supplier:

• Offers a tested and proven purge compound that is better than virgin resin, regrind or home remedies.

• Provides information to ensure the proper CPC is selected for the material and machine application.

• Trains your operators for the proper method needed to ensure desired results. Use the method directed first and modify when approved from management.

ABOUT THE AUTHOR: Dave Denzel is a technical manager at iD Additives, Inc. and holds a BS Degree in Technical Education with Concentration in Plastics. He has more than 38 years of experience in plastics industry management and processes. Denzel assists clients in training, troubleshooting, and selecting the proper commercial purge compound for injection molding, extrusion and blow molding. Contact: 708-588-0081 x2888; ddenzel@idadditves.com; idadditives.com.http://idadditives.com

Related Content

Run Lots of Colors? Time to Consider a Commercial Purging Compound

Processors who use commercial purging compounds will see a reduction in scrap levels, machine downtime and overall cost.

Read MorePurgex Purging Compounds Celebrates Founder's Induction to Plastics Hall of Fame and Holds Technical Seminars

NPE2024: Purgex team hosting technical seminars throughout the show with industry pros.

Read More'Dual Action' Purging Compound Accelerates Color Changes

NPE2024: Shuman Plastics’ Dyna-Purge Division launches Dyna-Purge L, extending its “3X technology.”

Read MoreBest Practices for Purging PHA and PHA/PLA Blends

Because bioplastics are processed at lower temperatures, purging between jobs requires a different process and purging agents than those applied for traditional resins.

Read MoreRead Next

Be Proactive in Your Purging Program

True, it can be tough to take a machine out of production, but a purging maintenance program should be thought of as a direct line to cost savings.

Read MoreThe Experts Speak: Seven Cost-Saving Purging Tips for Compounding Twins

Purging gurus from the material, machinery and compounding sides of the industry offer their insights on best practices and tips that can keep your compounding twin-screw extruder up and running.

Read MoreA Planned Purging Program Can Boost Your Hot-Runner Efficiency

Molders can increase the efficiency of their hot-runner operations if a strategic approach is developed to address the need for required resin and color changes.

Read More