From NPE 2000: What's Hot in Hot Runners

Closer cavity spacing, in-press serviceability, improved valve gates, smarter controls, quick-ship standard manifolds, and Internet e-commerce were leading themes in hot runners at the big show in Chicago.Hot-runner components were one of the largest categories of injection molding products exhibited at the triennial NPE show in June.

Closer cavity spacing, in-press serviceability, improved valve gates, smarter controls, quick-ship standard manifolds, and Internet e-commerce were leading themes in hot runners at the big show in Chicago.

Hot-runner components were one of the largest categories of injection molding products exhibited at the triennial NPE show in June. The huge number of new products exhibited, plus a few that came to light since then, confirms trends of recent years toward tighter nozzle pitches, greater durability, easier servicing in the press, more versatile valve-gate systems, and controls that provide more kinds of warnings and protections against faults. Two newer trends evident at the show are the proliferation of standardized systems that cut cost and lead time, and the growing ability to specify and order components in record time via the Web.

Hot runners on the Web

Specifying and buying hot runners has become a kind of computer game. On-line catalogs have already existed for a few years, but their functionality has become greatly enhanced. An example is Mold-Masters’ new MIM Speed Program on its website, www.moldmasters.com. You can configure a system, view and download a 3D CAD solid model, order the system, and get an immediate price and delivery quote. Afterwards, you can track your order’s status on-line. Mold-Masters promises to deliver systems ordered on-line in as little as five working days and a turnkey hot half as soon as two weeks.

D-M-E also introduced at NPE new “e-shop” capabilities at www.dmeco.com. These include a searchable catalog, downloadable 2D and 3D CAD files (in a choice of 22 formats), pricing, real-time ordering and order tracking, and monitoring of billing and shipping status of all orders (on-line or not), and customer order history.

Husky also launched a web-enabled version of its Hot Runner Design Center at www.hotrunners.com. It offers design guidelines, a catalog, downloadable 2D CAD files, and a form for requesting a quote. Pronto two- or four-drop hot halves can actually be ordered on-line for delivery within four weeks.

Incoe introduced at the show its new on-line catalog at www.incoe.com, with downloadable drawings and on-line ordering capability. The catalog also features the Compass On-Line Selection System, a “wizard” that helps you select the best components for an application.

Faster deliveries

Use of the Internet is not the only way hot-runner suppliers have accelerated deliveries. Dynisco HotRunners announced its LINKS program to decrease lead times by up to 44% through earlier coordination with the moldmaker. The goal is to develop the hot-runner concept in parallel with the mold concept instead of afterward. Dynisco created a system to provide preliminary drawings of the hot-runner system to the moldmaker at the mold-concept phase. This allows problems to be worked out sooner, preventing rework and delays.

D-M-E came out with the Meteor line of standardized hot-runner systems, designed for same-day shipment and low cost. These stock manifolds come in two- and four-drop configurations and “in-line” and “X” patterns. Meteor1 manifolds have a machined main flow channel, but the customer has to machine nozzle locations and fit the end plugs. Manifolds can be shipped with all other standard components needed for a complete hot half.

Meteor2 manifolds go a step further, in that D-M-E machines vertical channels and installs end plugs before shipment. Lead time is a week or less. And Meteor3 is a turnkey hot half, whose three-week delivery time is said to be the shortest available.

New standard manifolds from Heatlock of Sweden are supplied here by DMS. They are ceramically insulated and come in straight, “X,” and “H” patterns with flow channels 6 or 8 mm wide. They are supplied from stock in unfinished form or can be shipped finished in two weeks.

Same-day delivery and low cost are claimed for new “X”-pattern stock manifolds that Incoe added to its in-line SSM (Standard Stock Manifold) series. They come with centers from 51 to 178 mm, three flow-channel sizes from 6 to 15 mm, and thermocouples.

Husky has expanded its Pronto quick-ship, low-cost hot-half program in two ways. First, buyers can now specify the exact nozzle length they need. Husky will perform all necessary design calculations, including thermal expansion. Previously, Husky offered only finite incremental nozzle lengths for Pronto hot halves, so customers had to design the mold to fit the nozzle and calculate thermal expansion themselves. Pronto lead time is still four weeks.

In addition, Husky now offers Pronto hot halves with standard mold bases from Omni Mold Systems of East Hartford, Conn. Two- and four-drop systems are available with mold bases from 7.875 in. square to 14.875 x 20 in. Mold bases with round or square cavities are supplied by Omni direct to the customer in one week.

Small is big

The miniaturization trend of recent years continued at NPE with numerous introductions of components to fit smaller molds. JPI Technologies billed its entry as “the world’s smallest hot-runner nozzle,” two of which can fit into a matchbox (see PT, Apr. ’00, p. 33). Minimum drop spacing is just 7 mm (0.276 in.) and minimum overall length is 25 mm (0.984 in.). The nozzle contains a replaceable thermocouple and 230-V heater.

New torpedo nozzles with 10-mm outer shaft diameter permit cavity spacing as close as 12 mm. VT Series nozzles are additions to Ewikon’s HPS III externally heated, 240-V line. Their slim design is suited to gating inside cores of cosmetics packaging that cannot tolerate gate marks. They have removable tips and lengths from 39 to 179 mm. Two versions can be installed from the front or rear of the mold.

D-M-E brought out several lines of components for micromolding. One is the HTS edge-gating system from Heisskanal Technik Schulte of Germany. These components have sealed edge-gate tips mounted directly in the manifolds and permit center spacing as close as 10 mm. Standard manifold configurations are 2x4, 2x8, and 2x16.

D-M-E also offers HTS point-gate systems for direct gating into the part’s center. Spacing can be as close as 14 mm. HTS valve-gate systems will become available in the first quarter of 2001. These are standardized, bolt-on hot halves (four- or eight-drop) with a pneumatic plate-actuated design. Minimum gate pitch has not been determined.

D-M-E also unveiled a competitively priced line for precision micromolding. The Stellar system fits center distances down to 17 mm. This externally heated system has front-loaded tips, seals, heaters, and thermocouples that are easily accessible while the mold is in the press. Interchangeable tips come in point-gate, through-hole, sprue-gate, and extended point-gate designs. Standard multi-nozzle assemblies have two to 16 drops.

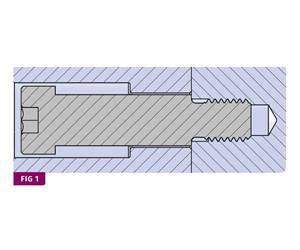

Pitches as close as 11 mm are possible with a new valve-gate mechanism from Gunther Hotrunner Systems. A cam plate actuated by an air cylinder moves all the valve pins simultaneously and eliminates the need for bulkier individual pin actuators.

Narrow-pitch valve gates in which dual plungers are actuated by one air cylinder are a new development from Seiki Corp. of Japan. The model SV32 has a 32-mm pitch. (This spring, Dynisco took over marketing of the Seiki Spear System in North America.)

Incoe has come out with the CCVG (Close Center Valve Gate) system for small to medium-size medical and electronic parts weighing from 10 to 90 g. Minimum pitch is around 1 in. It can be powered by air or hydraulics.

A mini valve-gate system capable of pitches down to 20 mm is new from Manner International, the 18-month-old U.S. office of Otto Manner Vertriebs GmbH of Germany. The mini system is designed for molding parts as small as 0.05 g in up to 128 cavities. Four valve gates can be air-actuated by a single plate.

One step up from its smallest hot-runner nozzles is the new 500 Series from Husky. Sized between the 250 and 750 Series, they are designed to mold parts weighing up to 50 g on center spacing of 1 in. (25.4 mm) for both hot-tip and valve-gate models. Tips, heaters, and thermocouples are replaceable in the press.

Fast Heat has improved its Micropoint Series nozzles, which provide minimum pitch of 0.600 to 0.670 in. A new patented tip design is said to produce laminar rather than turbulent flow at the tip, thereby dramatically reducing wear from glass or fillers. Although they last much longer than even carbide tips, the new tips are replaceable, along with heaters, and thermocouples.

Yudo has shrunk some of its valve-gate nozzles to permit close pitches in high-cavitation closure molds by eliminating the heater. The nozzle is made of copper and is designed to pull heat from the manifold.

New way to apply heat

A new heating technology that can reduce the size of nozzles and manifolds is being introduced by Watlow. Its patented “thick film” heaters consist of a thin stainless-steel support covered with a glassy dielectric film. Resistance-heating circuits are “printed” in a precise pattern on the glassy film and then sealed under another glassy dielectric layer. The result is much thinner than traditional coiled wire and tubular heaters, allowing tighter nozzle pitch and thinner manifolds.

Watlow says thick-film heaters provide precisely distributed wattage for exact temperature profiles at up to 925 F. Their low thermal mass provides much quicker heat-up, and the insulated stainless support drives the heat in just one direction—toward the plastic. Film heaters are wrapped tightly against the nozzle body, providing uniform contact and eliminating hot and cold spots, Watlow says, and they can easily extend down to the tip area. Manifold heaters cover the entire manifold and conform exactly to its shape. Problems of current leakage and burnout due to moisture condensation are said to be eliminated. Also, the thermocouple can now be inserted directly into the nozzle rather than into the heater coil, providing more accurate temperature readings.

Watlow is supplying the heaters both to molders and to makers of hot runners. Osco is one of the first to use the thick-film heaters in its new High-Endurance nozzles, which are aimed at the most demanding applications. For extra wear resistance, the nozzles are hardened throughout and have nitrided flow channels. Flexible leads extending all the way to the heaters are more resistant to damage.

The film heaters are also used in Osco’s new DSR 30 Direct Cold-Sprue Replacement bushing, which can fit into a 0.75-in. or 1-in. nozzle bore in a standard mold base. (Previously, only a more expensive nozzle with a cast-in heater could fit 0.75-in. bores, Osco says.) DSR bushings are designed to retrofit cold-sprue bushings without any remachining. They have replaceable tips, heaters, and thermocouples.

Valve gates galore

The number of new valve-gate developments reflects the growing prominence of this technology as a tool for improving part appearance and taming unruly molds. Husky, for one, has added sequential valve gating to its capabilities. Its new valve-gate sequencing controller has a Windows NT graphical touchscreen interface. It supports all types of sensors and provides a response time of 1 millisec.

A Windows PC-based valve-gate sequence controller is new from Incoe. This self-contained, cart-mounted unit can include its own hydraulic or pneumatic power source. Each of up to 40 gates can be programmed for two open/close sequences per cycle based on either screw position or time. A coinjection program is included.

Plasthing reports that its valve gates are being used for the Coralfoam process, which is available for licensing from Coralfoam Ltd. in the U.K. This process involves injecting a solid part and then opening the mold (or retracting a core) to permit the foam to expand in the center of the part after the skins have solidified. The result is a stiff, lightweight part with selective areas of thickening and a fairly smooth, printable surface.

Ewikon introduced a nozzle design intended to eliminate valve-pin deflection caused by thermal expansion. Its new 240-V HPS III valve-gate nozzle places the hydraulic or pneumatic actuator in the front section of the nozzle on the parting-line side of the manifold. Unlike conventional designs, the drive unit is not sandwiched between the clamp plate and manifold, so it is subjected to lower temperatures. Seals last longer, and the pin does not extend through the externally heated manifold.

Ewikon also introduced a large version of the HPS III valve gate with melt channels up to 22 mm diam. for automotive parts such as fascias, consoles, and bumpers. If there is a long distance between the manifold and gate, flexible extension pipes can screw into the manifold and valve-gate nozzle so as to move the nozzle closer to the part and retain a short valve pin. The flexible extension pipes absorb the expansion of the externally heated manifold.

Fast Heat’s new Elite Series valve gates are the first from this company and are said to have a number of unique features. One is a socket on the side of each valve body that allows the pin length to be adjusted with an Allen wrench while the machine is operating. Adjustments that formerly took up to 12 hr now can be accomplished in seconds. Although a single rack and pinion can drive up to six valve gates, each gate has its own fine adjustment of gate vestige. The rack-and-pinion drive system (hydraulically or pneumatically actuated) is reportedly immune to “blowback” from melt pressure in the cavity.

Fast Heat also says this valve gate has unique advantages for molding with glass fibers. The valve pin rotates during injection, which is said to “comb” the fibers away from the pin orifice rather than cutting them.

As in some other newer designs, the melt passes around a spreader needle and meets the pin only 0.160 in. from the gate, which is said to result in better pin alignment, less pin wear, reduced shearing of the melt, and easier color changes.

The self-contained Elite valve-gate modules fit standard Elite LV Series bushings and can process parts weighing from 1 to 2000 g. The valve gates can be serviced individually in the press.

Like the foregoing product, Incoe’s Clear-Flo (CF) valve gate keeps the melt away from the valve pin until just before the nozzle exit, thereby reducing flow lines. Following a major redesign, the CF series reportedly provides improved flow and easier color changes. It also now has replaceable seals and interchangeable end caps and tips so nozzles can be adapted for running different materials. Choice of hydraulic or air actuation is also new.

In the past year, Yudo has come out with several new valve-gate developments. Its Single Valve III series has a concentric actuating cylinder that surrounds the valve body rather than sitting behind it, thereby reducing mold height. This series includes models that can fill parts weighing more than 1.1 lb with a single nozzle.

The shortened Single Valve III nozzles are an advantage in Yudo’s new Yuri-Combi System for stack molds. This system mounts two opposing valve gates facing each other in the stationary and center plates. The two valve gates pass the melt from one to the other, eliminating the conventional long nozzle that extends between plates and can interfere with parts ejection. The Yuri-Combi system is also said to eliminate drool and to reduce holding-pressure requirements.

More nozzles & bushings

Common themes among new general-purpose components are easily replaceable tips, thermocouples, and heaters; improved wear resistance; and free-flow open bores.

ALBA Enterprises introduced K Type nozzles, its first with front-removable tips that permit easy replacement in the press. K nozzles are designed for closures.

Replaceable heaters and thermocouples for easy maintenance are also featured on new RCB nozzles from Dynisco HotRunners. These open-bore products are designed for small to medium shot weights and high cavitation.

Dynisco also offers the new Spear System ESN probes, which have removable tip heaters and are less expensive than other Spear nozzles. Also new from Spear and Dynisco are externally heated nozzles to supplement Spear’s torpedo types. These ESP probes have a free-flow open bore suited to running engineering resins. They also have replaceable tips.

Fast Heat’s new Precision II bushings and nozzles come in 11 gating types and four body/head styles, all designed for mid-sized parts with a medium pitch. They have wear-resistant, replaceable tips and thermocouples. Also replaceable is the new sleeve heater, which has a swaged-type, compacted insulation that resists moisture absorption and provides long life. This type of heater construction has been used before in bushings, but was not previously replaceable.

Side gating without generating a cold slug is possible with new multi-tip nozzles from Gunther. Each tip extends right up to the part through a split insert around the nozzle, leaving no land. A nozzle can have up to four tips.

New Heatlock products from DMS include three kinds of filter nozzles and the NPT-1-Xtnd bushing with extended needle tip. It allows direct gating into highly profiled surfaces and/or restricted areas. It has an open flow channel and ceramic insulation.

Superior mixing ability that both eliminates flow lines and allows fast color change is claimed for Husky’s novel 750 Series UltraFlow nozzle tip. Its reportedly unique design splits melt into a straight longitudinal flow along the torpedo and a spiral flow around the torpedo. The two flows mix, providing thermal homogeneity and erasing flow lines with metallic pigments or fillers. The UltraFlow nozzle tip can be retrofitted directly to Husky hot tips and valve gates.

Incoe’s new FC (Fast Cycle) systems are designed for fast-cycling closure molds of two to 96 cavities. They include special tips designed for extended life and quick color change. These systems have replaceable heaters and are serviceable from the parting line while in the press.

A newly expanded line of hot-runner components from Melt Design now includes tips and thermocouples that can be replaced in the press. Different styles of screw-on tips are now interchangeable on the same nozzle body.

Mold-Masters also expanded its new standard line of MIM (Metal Injection Molded) Dura products, which replaces the former Dura series. It now includes five nozzle families of different shot-weight ranges (Femto, Pico, Deci, Centi, and Hecto), 15 gate configurations, and manifolds for two to 16 drops (up to 128 with bridging).

A new cast round manifold with bolt-on drops is the first of its kind, according to Plastic Engineering & Technical Services (P.E.T.S.). The manifold can now be removed in just one step. Also, the “floating” drops allow for thermal expansion.

Duratherm has quietly made several advances in bushings and torpedoes over the last couple of years. Its patented integrally heated, free-flow bushings reportedly make dramatic improvements in processing difficult engineering materials such as PPS, PPA, and 30% glass-filled PET. Patents are pending on two developments: circumferential “thermal isolation grooves” at the bottom end of the bushing that keep the tip from overheating, and “thermal adjustment rings” that reduce the tendency of bushings to run hottest midway along their length.

Duratherm also introduced patented center-fed torpedoes in which the melt flows in a straight line rather than turning a 90° angle, as in the usual side-fed design. As a result, they are said to process engineering materials better. These 240-V torpedoes reportedly eliminate the large cables used with competing designs that have low-voltage tip heaters.

Special-purpose products

In addition to the foregoing general-purpose products, some new hot-runner developments are tailored for more specific applications:

PET preforms: A new manifold from Electra Form Industries (EFI) reduces shear heating and the generation of acetaldehyde (AA). Molding trials with the ExStream “low-AA” manifold and a 48-cavity mold reportedly produced average AA values of 1.0 micrograms/liter, a maximum of 2.2, minimum of 0.58, and standard deviation of 0.43—all said to be well below the industry standard. This manifold is now offered on all EFI preform molds and as a retrofit to existing molds from any vendor.

Plasthing says its internally heated, 24-V valve gates are starting to find use in PET preform molding. And Dynisco has expanded its activity in this area by building a valve-gate system for a 48-cavity preform mold. Previously, Dynisco supplied thermal-gate systems for 16 or fewer cavities.

Large parts: New from Fast Heat are Elite LV Plus Series bushings and nozzles for parts of up to 8.8 lb. They have integral heaters, replaceable tips and thermocouples, interchangeable head styles, and four tip styles. Redesigned sprue tips have a new heat barrier that reportedly yields smaller gate vestiges (0.040 in.) Also new are pinpoint tips that use Fast Heat’s “Flat Gate” approach of injecting in a ring. This reportedly produces pinpoint gate vestiges of only 0.010 to 0.020 in., even on parts of up to 8 lb. The previous size limit for pinpoint gates with small vestiges was about 0.9 lb, says Fast Heat.

Gears: Yudo has a new multi-tip nozzle with three evenly spaced gates, designed to provide exact concentricity in gear molding.

Another multi-gated nozzle from ALBA Enterprises is the smallest of its type the firm has made. It has three tips within a 5.5-mm-diam. bolt circle and is designed for parts like gears that need exact concentricity around a center hole. Overall nozzle diam. is 26 mm.

News in controls

New hot-runner temperature controllers feature current (amperage) displays to identify heater failures, hot-swappable components that allow replacement on the fly, graphical displays of mold layout, and a growing number of fault-detection functions, some of which can work around failures to prevent downtime.

For example, ALBA Enterprises is offering the new Q-Star temperature controller from Mold Control Systems. This compact PC-based system has capacity for 24 to 240 zones. Its 15-in. color touchscreen display is designed to resemble a control panel. It offers 15 amps per zone, SPC data logging and analysis, fuzzy-logic power control, amperage display, global and group functions for fast set-ups, and hot-swappable components.

Hot-swappable modules for each zone are also a feature of the new Pulse control system from Fast Heat. It has a simple touchpad and graphical LCD display that can be detached from the control cabinet for remote mounting. It supports up to 12 zones with “FT2” advanced autotuning technology and can store 10 set-ups. One screen displays setpoint and actual temperatures for each zone, as well as amperage and percent power. Another displays zone temperatures as bar graphs.

The latest from Athena Controls is the 12-zone HRCX controller. It is similar to the firm’s HRCE model for 12 to 20 zones but comes in a smaller package and offers 5 amps per zone vs. 15 or 30 amps for the HRCE. It can store tool set-ups, supply basic diagnostic information, and display current output for each zone.

D-M-E brought out three upgraded Smart Series control products. The SSH-10-12 is a compact, self-contained, single-zone unit with microprocessor-based PID control. The SSM-15-02 is a similar one-zone module designed for use in multi-zone systems. Both have new larger digital displays (the SSM shows temperature and setpoint simultaneously), a setpoint pushwheel that permits adjustment before turning on the power, improved PID logic, upgraded SmartStart for heater bake-out, and improved SelectiveCycle programming for high-speed power output. Both also feature percent power display and bumpless transfer to provide uninterrupted operation when a thermocouple fails. The SSM module can be used with the new TAS-05-12/11 module, which can control up to 63zones and has an audible alarm.

Amperage display is a new option on the 12-zone GLC 2K controller from Gammaflux. The company also enhanced its top-of-the-line 9500 Series controller for up to 256 zones with new Mercury software that provides faster start-up and allows the operator to begin programming immediately. Mercury software is configurable by the user. It also has improved graphing capabilities to show the last 100 samples of mold history. (These two controllers are also sold by Husky under its own label.)

A lower priced controller for small systems is Gunther’s new DP 230-V “value-packed” controller. It has one to five zones of 16 amps each. The LED display shows set and actual values.

Incoe’s newest control system is the MTC (Multiple Temperature Controller), which comes in 15-zone modules for up to 105 zones. Each module has its own touchpad and LED display of set or actual temperatures or amperage. Each zone can be programmed with four different temperatures. Also available is a PC-based touchscreen control interface, which displays a 3-D graphical model of the hot-runner system.

At the show, Orycon brought out a Windows PC interface for its new 980 Series, 12-zone, fuzzy-logic controller (PT, Jan. ’00, p. 11). The PCI-980 interface can monitor and control up to 10 of the 980 Series modules, for a total of 120 zones on one or more presses. The PC can save graphic displays of the part being molded, notes on critical part-quality criteria, and production data such as part count, target count, cumulative uptime and downtime, and total kwh consumed by the job. The system can even actuate an alarm when the target part count is achieved. The 980 controller includes such features as amperage display, bumpless transfer, and field calibration by the customer.

P.E.T.S. is offering new Windows NT control software that can run on any PC or laptop to control the firm’s 851-4 temperature-control modules. New SSMC727 software offers the SPI communications protocol, automatic shut-off when a shorted or miswired thermocouple is detected, auto switch to manual mode if an open thermocouple is detected, and automatic internal switching that lets a zone remain operating if a thermocouple is reversed.

A compact “universal Controller” that can run virtually any hot-runner system of any number of zones is new from Thermal Valve Gating. It uses standard Watlow components.

Finally, Yudo is now selling temperature controllers in North America to accompany its hot-runner systems. These microprocessor systems offer PID or fuzzy-logic control, heater failure indication, and open thermocouple indication with automatic switch to continued operation in manual mode at the same setpoint.

Husky’s new 500 Series nozzles illustrate two key trends in hot runners—ability to run small parts in closely spaced cavities and replaceable tips, heaters, and thermocouples that permit servicing in the press.

New hot-runner websites let you configure and order systems and download CAD drawings. Incoe’s new on-line catalog also features a “wizard” that helps you select the best components for your application.

D-M-E’s new Meteor standardized manifolds are designed for same-day shipment and low cost. They can be shipped with all other standard components needed for a complete hot half.

Among new close-pitch components for micromolding is the HTS edge-gating system from Germany, introduced to North America by D-M-E. Sealed edge-gate tips mounted directly in the manifolds permit center spacing as close as 10 mm.

Among many new developments in valve gates is this mini system from Manner International, which permits pitches down to 20 mm. As in some other new systems, multiple valve gates are actuated by a single plate.

Watlow’s new thick-film heaters for nozzles and manifolds have low thermal mass for fast heat-up, provide 100% contact with the area to be heated, are immune to burnout from moisture, and take up very little space.

New Yuri-Combi system from Yudo is designed for stack molds. Melt is passed between plates by two opposing valve gates, rather than by a long nozzle that can interfere with part ejection. Note the short Single Valve III nozzle in the stationary platen at left—its drive cylinder fits around the nozzle rather than behind it.

Athena Controls’ new compact, 12-zone HRCX controller displays amperage for each zone—a feature useful for troubleshooting heater failures.

Husky’s unusual 750 Series UltraFlow nozzle tip splits melt into a straight longitudinal flow along the torpedo and a spiral flow around the torpedo. The two flows mix, providing thermal homogeneity, erasing flow lines, and speeding color changes.

Related Content

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More