Full Plate of New Technologies on the Table at EVCO Plastics

A new low-pressure molding process, 3D printing of production parts and prototype tooling, collaborative robots, and process monitoring with automatic QC are all on the menu.

Managing nine plants in the U.S., Mexico and China with more than 1400 employees and 183 injection machines from under 100 tons to 3500 tons; and serving business segments as varied as medical cleanroom molding, thin-wall packaging, and large parts for automotive, agricultural equipment and appliances—all that might seem more than enough to keep one company busy. Not at EVCO Plastics. Based in DeForest, Wis., the custom molder and contract manufacturer is pushing ahead to adopt a handful of new or enhanced technologies to expand its services and capabilities.

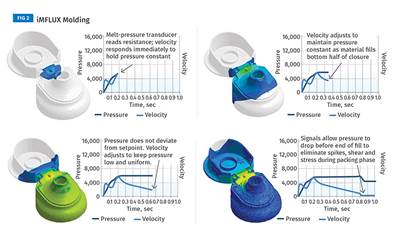

The newest item on the list is launching the iMFLUX low-pressure molding process from a new subsidiary of Procter & Gamble. This novel process-control concept shows promise for reducing cycle times, melt temperatures and clamp-force requirements, while improving part quality and consistency (see March ’18 feature article). Starting last month, EVCO is installing iMFLUX controls on five or six machines running some of the company’s most challenging jobs in packaging and plumbing. The first is a 400-ton Toyo press running a Noryl pressure vessel, where EVCO hopes to increase weld-line strength with the new process. Next in line will be Husky packaging machines running 64-cavity stack molds, where “saving an extra second in cycle time would be nice,” notes company president Dale Evans.

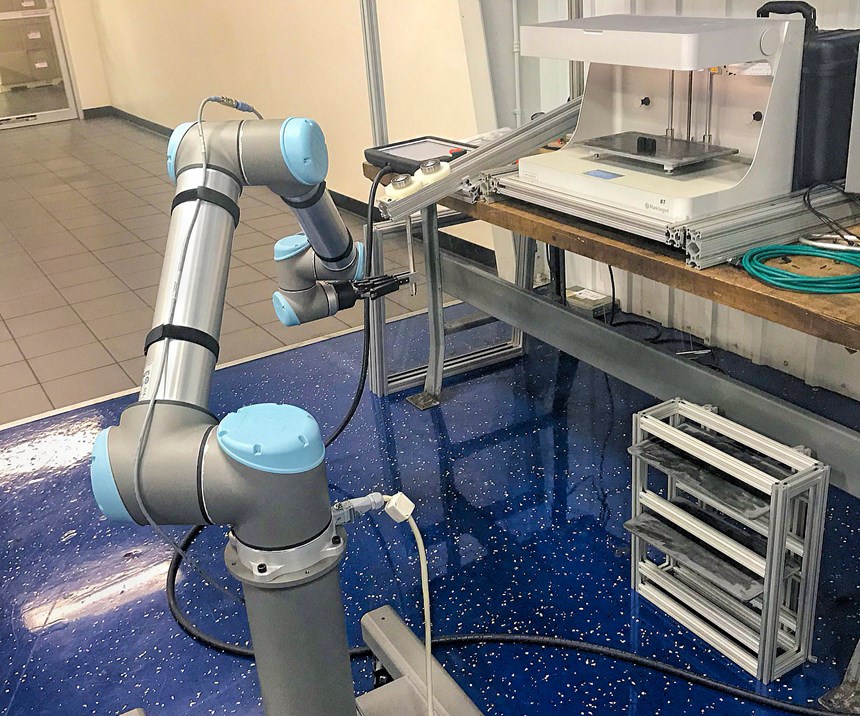

Other new initiatives are in 3D printing. One aspect is printing metal-powder mold inserts for prototyping new injection molded parts. Another is branching out into 3D printing as a process to complement injection molding for both prototypes and short runs of up to 600 parts. The firm is building a “printer farm” of 3D printers that will be served by collaborative robots from Universal Robots (UR) for unloading finished parts. EVCO already has 12 Markforged printers that use the fused-filament fabrication (FFF) process, as well as that firm’s unique continuous filament fabrication (CFF) technique, which uses two heads to lay down molten polymer together with continuous glass, carbon or other fiber reinforcement.

EVCO has other uses for UR collaborative robots, or “cobots,” including assembly, insert loading and boxing parts. Interfaced to the injection press, these are flexible and cost-effective automation tools, says EVCO automation engineer Jimmy Lee. The cobots free up labor from simple, repetitive tasks. “We have labor shortages like everyone else,” Lee explains. “Vision-assisted cobots let us use people for higher-level functions.”

And another important new venture for EVCO is launching the firm’s first painting line. It will start production soon, pending customer approval of UV-cured sample parts. The first job will be electrical housings, followed by lawn/garden and heavy equipment.

In addition, EVCO is adding more intensive process monitoring of its injection machines, which Bernie Degenhardt, automation manager, describes as one of the company’s initial steps into Industry 4.0. He says the goal is to tie together production and process monitoring and automatic quality control into one central system capable of archiving large amounts of historical data. This is starting in the firm’s medical molding operation, which requires extensive documentation of product quality.

Evans explains that over the past 20 years, all eight of EVCO’s North American plants have employed a Syscon-PlantStar system for production monitoring. “I can see the cycle time of machines in Georgia or Mexico, and real-time scheduling tells us when jobs will be done and helps us schedule people, materials and equipment.”

The firm also uses the Plantstar system for monitoring sensors on plant systems such as central chillers, air compressors and power usage. Now EVCO is pursuing real-time process monitoring on its injection machines. The machine controls monitor sensors for cavity pressure and other parameters on every shot to make accept/reject decisions. The PlantStar system archives 10 variables of process data—temperatures, speeds, pressures, water flow, and part weight—from machines of different brands and model years. The PlantStar system can also send out alerts and can signal a robot to segregate nonconforming parts after a weight check. The system is also monitoring auxiliary equipment such as dryer temperatures and water flow and pressure from mold temperature-control units.

Related Content

Next-Generation Workhorse Ultrasonic Welding Machines

NPE 2024: Rinco Ultrasonics’ line of standard ultrasonic welding machines significantly upgraded.

Read MoreOxygen Permeation System Also Tests Relative Humidity

Ametek Mocon expands Ox-Tran 2/28 instrument portfolio

Read MoreMetaspectral to Advance Vision Technology for Recycling

Company received further funding from British Columbia’s CleanBC Plastics Action Fund

Read MoreInline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

Read MoreRead Next

A New Way to Mold Better Parts Faster and Easier

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More