Hasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

Tuesday at its booth, Hasco kicks off with a happy hour at 3 p.m. before a cake-cutting ceremony at 4 p.m., as the German company marks a century since its founding in Lüdenscheid by Hugo Hasenclever in 1924. In 1957 when Rolf Hasenclever took over the company following the passing of his father, it was the next generation’s concept of a modular system applying standard mold units (which was patented in 1960) that established Hasco as foundational to injection molding and moldmaking.

Fast forward six decades and many of those standard mold components for modular tools can soon be purchased online via a new website. Brenda Clark, engineering manager at Hasco, says when the company’s German operations first implemented online ordering, e-commerce accounted for 12% of total sales. Today, that figure is 30% and should increase even more once online ordering is available in the U.S. and Canada. “We wanted to make sure the website was in good shape and that the minute people log in, they can purchase items and there are no hiccups,” Clark says.

Stocking more than 100,000 individual products, the online shop is built with a responsive design, making it user friendly regardless of the visitor’s device, and the consolidated menu has simplified navigation which is available in 16 languages. Testing is ongoing with the official launch anticipated in June. At the show, Hasco will share a demonstration model of the site, which is about a lot more than online ordering. “We want to show people how to utilize it,” Clark says, “because it’s not just ordering; it has so much more built-in.”

Hasco says the new site enables users to calculate, configure and order products at any time in a few clicks, with a mold base assistant available to simplify and speed up processes. CAD data download is possible in more than 40 data formats, and CAD direct insert drivers enable simplified 3D data upload into a variety of CAD systems. Parts lists for cost calculation and ordering can be exported and, once logged into their account, customers can see past and future orders to determine internal inventory.

In cooling, Hasco introduces the USA system portfolio, the series 200 and 300 portfolio (consisting of numerous standard components), a high-temperature range, a Push-Lok system, a stainless steel and clean-break range, and a multicoupling system. “It offers the same high-quality made-in-Germany fittings that are now also available in inch,” Clark says.

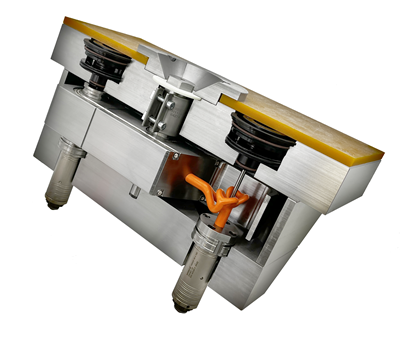

In hot runners, Hasco features the Shadowfree technology for eliminating shadow formations in valve-gate systems. The 3D-printed, screwed-on system splits the material flow into streamlined channels to evenly flush around the needle, reuniting the melt streams at the point where the valve pin enters the melt channel. Hasco’s booth has a sample and a cutaway model of the product to help molders visualize how the technology works.

To display its Mold Track System, Hasco has installed the system at its booth and will allow visitors to track movements, including of designated Hasco employees to show its accuracy, throughout the show. Applying ultrabroadband radio modules and an intelligent software platform, Mold Track offers localization accuracy down to a few centimeters, as well as other insights into a tool. “It lets our customers know exactly where the mold is,” Clark says. “Is it stored in aisle six, 10 feet off the ground or is it in molding machine No. 29 running? Mold Track will tell us its movement, including if it’s been dropped or damaged. It will also alert you if the mold leaves a certain area.”

Hasco’s concept of a modular system applying standard mold units was patented in 1960. Source: Hasco

Related Content

What You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreRead Next

Hasco Mold Trackers Provide Pinpoint Tracking of Injection Molding Tools

Hasco says its Mold Track’s ultrabroadband radio modules and intelligent software platform provide tool location accuracy down to a few centimeters.

Read MoreFakuma 2023: 3D-Printed Manifold Eliminates Dead Spots Behind Valve Pins

Hasco’s new Streamrunner Shadowfree 3D-printed hot runner manifold is said to eliminate areas of poor flow behind valve pins.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More