HASCO America, Inc.

270 Rutledge Road

Unit B

Fletcher, NC 28732 US

877-427-2662 | 828-650-2600

quotes.america@hasco.com

hasco.com/en

About HASCO America, Inc.

HASCO Precision for Moldmaking since 1924, the reliable partner for moldmaking standard mold bases, plates, components, and hot runners.

Since it was founded in Lüdenscheid, Germany, in 1924, HASCO has developed to become the international leading supplier of modular standard mold units and accessories. The basic idea of standardization revolutionized moldmaking worldwide and is still one of the key success factors.

HASCO, the pioneer of moldmaking for 100 years. Supplying moldmaking with standard mold bases, plates, components, and hot runners. Ever since the modular standard component system was invented and patented in 1960 by HASCO, we have been the leader for standardization in modern moldmaking. Working with only highly qualified suppliers in Europe and North America, enables us to offer the most secure and proven supply chain to our customers worldwide. With more than 100,000 certified, high-quality standardized parts from a single source, makes HASCO your only reliable full-range supplier in the industry.

- Continuous product identification and traceability

- Innovative online website and web shop

- Standardized, modular system guaranteeing You maximum productivity

- Fast and reliable delivery around the world

- More than 35 Global HASCO locations, offering technical support and local stock

- Certified quality management system to DIN EN ISO 9001:2015

HASCO the Original, Your reliable partner for standardization, yesterday, today, and tomorrow.

IS THIS YOUR COMPANY?

Video Gallery

HASCO 100 - Celebrating around the world

NEU! HASCO Cooling Tornado Z9665/...

Warum möchte jeder den neuen Cooling Tornado von HASCO einsetzen? Weil es noch nie so einfach war, die Zykluszeiten im ...

NEW! HASCO Cooling Tornado Z9665/...

Why does everyone want to apply HASCOs new Cooling Tornado? Because improving your cycle times in the injection moulding ...

NEU! Auswerfer Verzögerungseinheit Z1725/...

Mit unserer Auswerfer Verzögerungseinheit Z1725/… bieten wir eine #smarte Lösung für die präzise Entformung und saubere ...

As Seen On Plastics Technology

HASCO America, Inc. Supplies the Following Products

- Bearings, Thrust

- Heat Pipes and Related Thermal Conductors

- Heaters, Heating Elements

- Hot Runner Components

- Hydraulic Components and Systems

- Injection Molding Nozzles

- Injection Molds

- Lubricants

- Mold Components

- Mold Grease

- Mold Steels

- Mold-cleaning and Maintenance Chemicals

- Mold/Die Management Systems

- Mold/Tooling Simulation and Analysis Services

- Nonmetallic Tooling Materials

- Physical/Mechanical Properties Testers

- Pressure Sensors, Transducers

- Quick-mold-change Equipment

- Release Agents--External (Spray or Wipe-on)

- Steels

- Temperature Controllers, Monitors

- Temperature Pyrometers, Sensors, Thermocouples

- Water, Oil Manifolds and Couplings

Editorial, News, and Products

-

Cooling Bore Creates Turbulent Flow

Hasco says its Cooling Tornado facilitates turbulent flow, boosting cooling effectiveness by up to 20%.

-

Ejector Delay Unit for Two-Stage Demolding

Hasco’s Z1725/… ejector delay unit enables two-stage ejector demolding so sprue and part are cleanly separated through a coordinated ejector movement.

-

Servo-Hydraulic Injection Molding Machine With an Electric Injection Unit Premieres

Fakuma 2024: Wittmann Battenfeld says the 2K SmartPower Combimould features a new electric injection unit option.

-

Slide Retainer Features Positive Locking Connection

Hasco’s Z1899/… compact slide retainer applies a ball catch for reliable locking.

-

Manifold Block Line Extended

Hasco has introduced Z920/... manifold blocks, extending the range with new connection threads and lengths.

-

Hasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

-

Hasco Releases UKCA Identification Stamp

Hasco’s Z4884/ stamps provide UKCA identification.

-

Mold Tracking, Simplified Cooling Line Coupling and More

NPE2024: Hasco, which marks its 100th anniversary in 2024, highlights multiple product lines making their U.S. show debut, as well as a revamped responsive website that simplifies online ordering.

-

Environmentally Compatible Mold Sprays

Hasco introduces all-synthetic lubricant, anti-corrosion and multipurpose cleaning sprays, many of which satisfy NSF certification.

-

Cable and Plug Range Heighten Electrical Safety

Hasco’s new H1251/… cable with aluminum shielding and PVC covering protects against interference signals.

-

Hasco Mold Trackers Provide Pinpoint Tracking of Injection Molding Tools

Hasco says its Mold Track’s ultrabroadband radio modules and intelligent software platform provide tool location accuracy down to a few centimeters.

-

RFID Applied to Hot Runner Systems

Hasco says the adapted variant of the Mold Tag makes it possible to read out all data on the hot half or a wired system directly on a smartphone.

-

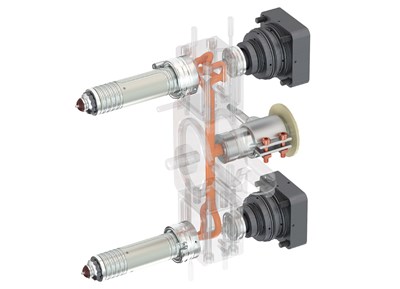

Interchangeable Needle Valve Pre-Chamber Simplifies Hot Runner’s Maintenance

Hasco’s Vario Shot Xgate features an interchangeable needle-valve pre-chamber to lower the cost and difficulty of maintenance.

-

Fakuma 2023: 3D-Printed Manifold Eliminates Dead Spots Behind Valve Pins

Hasco’s new Streamrunner Shadowfree 3D-printed hot runner manifold is said to eliminate areas of poor flow behind valve pins.

-

Manifold Blocks for Flexible Cooling Circuits

Hasco’s Z920/... manifold blocks create a centralized inflow/outflow location that enables the use of shorter hoses in mold heating/cooling systems.

-

Hasco Reveals Fakuma 2023 Plans

Hasco will highlight new 3D-printed hot runner components, digital products, mold tracking, mold components and more at the show.

-

Line of Locating Ring Adapters Expanded

Hasco has added four new sizes to its Z7500/... locating ring adapters, which enable accurate installation of injection molds.

-

Stainless Steel Sealing Plugs Offer High Corrosion Resistance

Hasco says the plugs, which are used for diverting flows in temperature control systems and sealing drilled holes, are ideal for use in medical and clean-room spaces.

-

Mechanical Limit Switches Communicate Mold Components’ Positions

Hasco says its new mechanical Z1430/... limit switches monitor the position of moving components like ejector pins and core pullers in injection molding tools.

-

Ejector Range Enlarged

Hasco says the approximately 600 additional new versions gives its ejector portfolio maximum demolding flexibility.

-

Multicoupling Range Extended

Hasco‘s quick-connect system for multiple cooling circuits has added U.S., French and HT versions.

-

Mold Designer, Mold Maker and Mold Repair Technician of the Year to be Named

The winners of the annual awards, including the new repair prize, will be announced at PTXPO by the Society of Plastics Engineers’ Mold Technologies Division.

-

Hasco America Inc. PTXPO Spotlight

Hasco discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

-

New App for Moldmakers Adds Functions, Part Scanner

Hasco’s new app has a number of new and augmented functions including an NFC (near-field communication) scan for reliable identification of original Hasco products.

-

Positioning Wedges for Precision Fixing of Mold Inserts

Hasco’s new Z1855/… positioning wedges allow users to change mold inserts in injection molding tools easily and lock them in place.

-

Tags Offer Digital, Forgery-Proof Product Identification

Hasco’s Mold Tag A5910/… utilizes RFID Tag (Radio Frequency Identification) and enables the digitalization of original standard mold units.

-

Stainless Steel Range of Cooling Components Extended

Hasco says the expansion helps meet the growing demand for mold cooling applications in the medical and cleanroom fields.

-

Faster, Fail-Safe Mold Changes with Multicoupling Hose System

Wirthwein Medical cut mold setup times in half, thanks to Hasco’s new multicoupling system for cooling lines.

-

New Mold Components & Controls at K 2022

At K 2022, Hasco will put forward a number of new products as well as a focus on digitalization.

-

Safe and Reliable Cooling Line Coupling

Hasco says its new clean break cooling range of couplers offer one-handed quick-release operation.

-

Drilled Thermal Insulating Sheets Come Pre-Machined as Standard

Hasco says the the thermal insulating sheets prevent uncontrolled heat dissipation and feature pre-drilled holes for guide pillars and clamp-plate screws, as well as centering and fixing holes.

-

New Cart for Hot Runner Control Units

Hasco’s new Co-Cart transport trolley allows the hot runner control unit to be positioned safely next to the mold and machine.

-

What Does Ukraine War Have to Do with Plastics?

Europe is feeling the heat from the abrupt halt to steel exports from Russia and Ukraine. Will the ripples reach to our shores, and when?

-

Heating and Cooling Hose Line Expanded

Hasco’s Push-Lok hose system for fast and secure connection of heating and cooling circuits has been extended to include more options.

-

Hot Runner Nozzle Range Maximizes Output, Minimizes Size

HASCO says it designed the Single Shot H6300/ nozzle series to allow the highest possible throughput and maximum process stability in the most compact design.

-

Mold Location System

Hasco’s Loc Check A5900/ is a magnetically mounted device that allows users to locate a mold wherever a mobile phone network is available.

-

Mold Awards Return in 2022

SPE’s Mold Technologies Division is again seeking nominees for the Mold Maker and Mold Designer of the Year after two-year hiatus; winners will be named at the PTXPO in March.

-

Hot Runner Nozzle’s Cable Location Shifted

Hasco has extended its Vario Shot nozzle range and optimized its cable location.

-

Latch Locking Units for Precise Control of Parting Planes

HASCO’s new latch locking units feature double-sided action and DLC-coated functional surfaces.

-

Fakuma: Metal Powder for Additive Manufacturing, Hot Runner Controls Among Show Intros

Hasco will unveil numerous new developments and additions to existing products, together with user-friendly tools, CAD features and digital services at Fakuma.

-

High-Temperature Cycle Counters

Hasco’s new mechanical cycle counters can be used at temperatures of up to 200 C (392 F).

-

Pre-Machined, Drilled Thermal Insulating Sheets

The sheets from Hasco feature pre-drilled holes for guide pillars, clamp plate screws, centering flanges and fixing holes.

-

Hot Runner Controller Line Extended

Hasco has introduced the Primezone H1281/ hot runner controller with 40 and 48 control zones, closing a previous gap and completing the range up to 96 zones.

-

New Hot Runner Controller Features Updated User Interface

Hasco’s new Primezone H1281/ hot runner control unit reportedly offers an intuitive interface reminiscent of a smart phone.

-

CAD Databases Extended With Key Information

Hasco has extended its CATIA, Siemens NX and Solidworks databases, including information like installation space, for more efficient mold design.

-

Hoses Handle a Range of Temperatures

Thermal protection hoses can be used at temperatures from -40 to 220 C.

-

20 Good Things to Come Out of 2020—Part 4

Good news was there if you knew where to look for it—in the pages of Plastics Technology magazine or right here on our website. Here’s a review of headlines you can feel good about.

-

3D-Printed Hot Runner Manifold

The additive manufactured Streamrunner hot runner system from Hasco eliminates sharp corners for improved melt flow.

-

Tooling: Two-Stage Ejector for Off Center Mounting

Hasco’s Z1697/ two-stage ejector targets off center mounting, particularly for larger molds where the ejector system activation requires high forces.

-

Tooling: Locating Rings Add Sizes

Hasco has added new inner diameters and location depths to its line of locating rings.

-

Tooling: Hose Provides Flexible Cooling

Hasco’s TempFlex Z976/ and Z977/ metal-braided hose provides assembly, interchangeability, and adaptability to any groove pattern.

-

K 2019 Report: More Control, Faster Ordering for Molds, Hot Runners

Online monitoring of existing systems and configuration and ordering of new molds were featured at K 2019, as were numerous advances in valve-gate controls.

-

Tooling: Expanded Mold Base Range, New Hot Runner Brand

Hasco will feature and expanded range of mold bases at K 2019, as well as launch its own hot runner brand with new Single-Shot individual nozzle.

-

K 2019 Preview: Molds and More at the Messe

Here’s news to look for in molds, mold components, hot runners and controls at the giant K fair in October.

-

Hasco Opens Hot Runner Technical Center in Austria

Hasco has headquartered its hot runner operations in Guntramsdorf since 2014; the new expansion features a SmartPower 120/350 injection molding machine from Wittmann Battenfeld.

-

Tooling: Flexible, Non-Twisting, Kink-Resistant Hosing

EPDM hose with textile reinforcement can be used to run water or steam.

-

Tooling: Compact Identification Stamps

Stamps are available for the standard international food, recycling and CE symbols

-

Hot Runners: Range of Ready-to-Install Single Needle Valves Extended

Ready-to-connect system—including nozzle; all the hot runner and connection components; the clamping, frame and nozzle retainer plate; and also the standard parts—can be directly assembled to the fixed mold plate.

-

Hot Runners: Control Features Adjustable Touch Screen

Hasco's H1280 series of controllers come in three sizes, including table top units, operating from 6 to 36 zones.

-

Tooling: New Mold Components at Fakuma Show

Automatic safety locks, mold status indicators, hose manifold blocks, online ejector configurators, and new flexible lifters.

-

Tooling: New Safety Couplings for Mold Cooling Lines

Hasco’s new couplings have an automatic safety lock.

-

NPE2018 New Technology Focus: Mold Components, Supplies, Maintenance

Advances include new approaches to tool maintenance and monitoring.

-

NPE2018 Technology Focus: Hot Runners

Technology being tailored to specific needs.

-

Hot Runners & Tooling at NPE2018: Smarter & More Specialized

Hot-runner technology, like the companies utilizing it, is becoming highly specialized, building in focused functionality for the application to be molded. Like most of the equipment in the cell around it, it’s also becoming smarter, sharing data and reacting to feedback from the press and more.

-

Tooling: New Standard Mold Components

Stack-mold actuators and mold monitors stood out from the crowd of new mold components at Fakuma 2017 from Hasco, Meusburger, Haidlmair, and Progressive Components.

-

News in Hot Runners & Tooling At Fakuma 2017 Show

Highlights included some unusual solutions to common problems, slim nozzles for close spacing, and controls with lots of zones, as well as a handful of new cost- and space-saving standard mold components

-

Tooling: New Hot-Runner & Mold Components Shown at Fakuma

New standard products for hot runners and mold bases.

-

Hot Runners & 3D-Printed Molds Headlined at K Show

Automotive was a key focus for hot-runner developments. 3D-printed plastic prototype tools were another highlight.

-

Smart Tool, Electric Tool

The old gray mold ain’t what she used to be. Or won’t be for long, if recent trends hold up.

-

Ten Intriguing Injection Molding Technologies of 2015

I know I’m leaving myself wide open on this one. I was asked, “What are the 10 most interesting injection molding technologies of 2015?” I should have pleaded eggnog hangover and politely declined.

-

Fakuma Show News: Hot Runners & Tooling

Hot-runner nozzles, manifolds, and controls, as well as other mold components and a new tooling concept made their debut in Friedrichshafen.

-

3D Printing’s Growing Presence Seen at Fakuma Show

Additive manufacturing appeared in tooling inserts, robot grippers, and molded parts.

-

Where Was 3D Printing at the Fakuma Show?

All over, and in a variety of roles.

-

Tooling at NPE: Valve Gates & Multi-Tips Top the News

There’s no letup in development of sophisticated hot-runner nozzles and controls. Here’s news in these and other tooling products at the show.

-

News in Hot Runners & Tooling At Fakuma 2014

Novelties included variable-pitch manifolds, mold servo controls, 3D printed plastic mold inserts, and flexible/formable cooling channels.

-

News in Hot Runners & Tooling at K 2013

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show.

-

K 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

-

TOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

-

Tooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

-

Injection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

-

News in Auxiliaries & Tooling at Fakuma Show

Late last month, Friedrichshafen, Germany, hosted Fakuma 2011, the largest European plastics show of the year, growing to be second in size and importance to the K show in Dusseldorf.

-

Bonanza of Hot Runners & Controls Introduced at K 2010 Show

At the world’s largest plastics show in Dusseldorf last fall, hot-runner and controller manufacturers introduced a flood of new developments in speed, size, accuracy, and reliability.

-

TOOLING: Standard Components and In-Mold Monitor at K 2010

K 2010 news in tooling aims at helping injection moldmakers speed product to market.

-

CAD Evolution For 3D Mold Design

Specially tailored packages of 3D computer-aided design software have been available to injection mold designers for at least a decade.

-

Hot-Runner News at K 2007

While a number of exhibitors at the “K” show in Dusseldorf are keeping their new entries under wraps until showtime later this month, some suppliers have released a few details on their new hot-runner components and controls.D-M-E will introduce the Bacchus hot-runner system for crates and packaging.

-

What's New at the Show in INJECTION MOLDING

At the big “K” Show next month, top billing goes to new all-electric machines aimed at every segment of the market, from general-purpose to high-end.

-

NPE 2006 News Wrap-Up: Hot Shots: New Nozzles and Controls Add Sizzle to Runnerless Molding

Electrically driven valve pins, a low-cost alternative to valve-gating, mold-mounted temperature controllers, and new components for fast color changes are some of a host of new components and systems unveiled at the giant NPE 2006 show in Chicago this past June. (Some brand-new introductions since the show are also included in this report.) The news includes runnerless products aimed at everything from micromolding to shot weights up to 17.4 lb.

-

NPE 2006 News Wrap-Up: Testing and QC--New Lab Instruments Stress Affordability and Convenience

Thermal and mechanical testers, color and appearance sensors, vision inspection devices and CMMs—the NPE had them all in more compact, economical, and easy-to-use models.

-

What to See at NPE 2006: Injection Molding

Energy-saving all-electric machines will continue to be a big draw at NPE, where new designs or upgraded models will be found in virtually every press maker’s booth.

-

K 2004 News Preview: Injection Molding

The diversity of electric machines will be on display at this year’s show, with several new all-electric versions in direct-drive and belt-driven versions.

-

Mold Designers Put the Web to Work

The internet is redefining the tool-design process. Some mold designers are finding that using the Web to manage a tool project can shorten lead times, cut costs, and make sure vital data get to all participants in a project.

-

NPE 2003 News Wrap-Up: Hot Runners

From complete hot halves to individual nozzles, a host of new products promise smaller gate vestiges, less maintenance, better temperature control, and lower cost.