Tooling at NPE: A Hot-Runner Bonanza in Orlando

NPE2012 Preview

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

You’d think hot runners rule the world from the displays at NPE—they certainly rule the show. Most of the emphasis is on valve gating and on doing more in less space. Of course, there will also be exhibits of new standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

VALVE GATES IN THE SPOTLIGHT

Two themes dominate in new valve-gate entries: electric drive and precise control. Electric drive appeals to clean-room molders and also provides opportunities for close control. For example, Ewikon’s electric valve gate is now available with an optional position encoder for higher process reliability.

Likewise, Synventive’s new eGate electronic valve-gate control permits individual regulation of each valve’s position, speed, acceleration, and stroke. Along similar lines, Synventive will show its new SynFlow technology for controlling hydraulic valve gates.

Mold-Masters will include its E-Drive servo valve gate in a workcell for coinjection of three-layer HDPE caps with a 3% to 6% barrier layer of EVOH in the center. This IRIS coinjection technology utilizes Mold-Masters’ E-Multi secondary injection unit and an instrument from IMD Ltd. of Switzerland (imdvista.com, U.S. office in Venice, Fla.)to test for the presence of the barrier layer. (IRIS barrier coinjection technology will also be demonstrated at the JSW booth in production of 0.5-mm-thick dairy containers.)

New VGS valve-gate sequencer from Osco controls up to eight pneumatic valve gates and is said to be “very low-cost.” Other new valve-gate sequencing controls will be shown from Mold-Masters, Thermoplay of Italy (at ALBA Enterprises), and DME.

Husky claims improved part consistency through precise stem closing in its new UltraSync valve gates. And Hasco America is touting improved process control with its new multi-cavity needle-valve system, due to simultaneous opening of all valve pins at a pressure setting. The Z31250/ Valve Gate Shot nozzles for molding caps and closures are pneumatically or electrically driven. Its heater and thermocouple can be replaced in the press.

DOING MORE IN LESS SPACE

Smaller components for tighter gate pitches is a continuing trend in hot runners. Ewikon’s new HPS III-MH multi-valve-gate system, shown for the first time in North America, is aimed at small parts with a 6-mm pitch. It has plate actuation of valve pins for absolutely simultaneous opening and closing.

Technoject offers new Heitec Flat-line nozzles in a linear arrangement that requires as little as 5.5 mm cavity spacing. They also come in valve gates with a minimum pitch of 9 mm. Mold-Masters claims 20% higher pitch density for its new Melt-Cube linear side-gate system, compared with circular systems. It will be running at CBW’s booth.

MHT Mold & Hotrunner Technology is offering to upgrade PET preform molds from 72 to 96 cavities and from 96 to 128 cavities by moving the cavities slightly closer together and adding a row of cavities on the left and right. This allows greater production without moving to a larger machine.

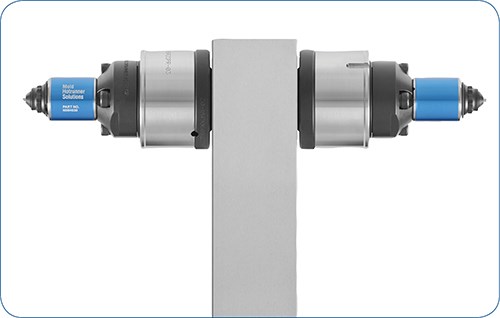

Likewise, Mold Hotrunner Solutions (MHS) is claiming to cut the cost of closure manufacturing through “ultra-compact” stack-mold technology. Its new Rheo-Pro iVG “back-to-back” internal valve-gate design allows MHS to build “short-stack” molds compact enough to fit in smaller machines. For example, a 48+48 stack mold can run in a 200-ton press and produce 96 bottle closures every 3 sec, or almost 3 million per day, making it 30% more cost-efficient than a conventional 96-cavity hot-runner mold.

Also in the smaller-is-better vein, Ewikon is showcasing its new HPS III-S slim-line nozzle for gating hard-to-reach areas of a part. It requires only an 11-mm well in the mold and can be spaced as close as 12 mm. The nozzle is offered as a hot tip, open tip, or valve gate—reportedly one of the smallest valve gates on the market.

MORE NEW NOZZLES & CONTROLS

Among other new hot-runner components at the show, Husky is emphasizing its Ultra SideGate nozzles for direct gating parts that can’t be gated effectively with a regular nozzle. They have a spring-loaded tip and nozzle body and are said to simplify nozzle installation because they eliminate the need for split cavities.

•Mold-Masters is unveiling its Vision line of angled systems designed specifically for automotive lenses and white-goods components. Also new is the TempMaster M1 hot-runner controller for up to 48 zones.

•Synventive’s new 09E “leak-proof” threaded nozzle is aimed at medium-size parts (up to 250 g shot weight). It threads directly into Synventive’s Plug’n Play pre-assembled, unitized hot-runner systems.

•The news from Osco includes MGN multi-gate hot runners for unit die mold systems like MUD and FITS. Osco’s new QSS Quick Set Systems are fully assembled, wired, plumbed, and tested hot runners on a mounting plate and “ready to shoot.” They’re said to be less expensive than a hot half.

Also new, Osco’s RGT Recessed Gate Tip is a nozzle tip with a gate recess dimple on its face. This dimple places the gate below the main molding surface, as is often desired for parts with labels or smooth-touch surfaces.

•ALBA Enterprises will show new Thermoplay screw-in nozzles for large parts.

•DME is introducing its D-Max single-drop hot sprue bushing for prototyping and short runs (see February Keeping Up).

•Technoject is displaying the recently enhanced Heitec Star-Line edge-gate nozzles with one to eight tips. They now come in a two-piece design with a body and crown, simplifying installation and maintenance. Separate heaters for body and tip also broaden the process window to handle difficult engineering resins.

•Polyshot will show its new M-Series nozzles in valve-gate and pinpoint versions. The multi-part tip allows the gate well area to be swept clean on each shot, helping prevent “gate burn” with sensitive resins like PC, PVC, and acetal.

•And DMS will bring out the next generation of Heatlock hot runners (no details available at press time).

NEW MOLD COMPONENTS

DME is coming to the show with its new DoveTail collapsible core for molding undercuts; a removable date insert that can be changed out with the mold in the press; and an expanded line of DIN and JIS sized pins, sleeves, and blades. Also new are Edge series pre-pocketed mold bases with top locks already installed.

Progressive Components is highlighting its recently introduced CVe mold monitor with built-in flash drive. This small electronic device records mold cycles and other data in a mold pocket (see Feb. ’11 Close Up).

Meanwhile, DMS is introducing “cloud” storage on the Web for mold data from its mold-mounted Rede Vault.

Ifw mould tec GmbH of Austria is showing its new CompactPull core pull for smaller machines.

Hasco has a new inclined sliding carriage, said to be the smallest on the market for releasing undercuts. Also new from Hasco is a vapor-deposited diamond-like carbon (DLC) coating that offers low friction and wear protection for moving mold parts.

For mold release, PCS Co. has a new Quick Cure NanoMoldCoating that lasts for up to 300,000 cycles. It can be applied to the tool in the press and is ready for molding in 15 min.

COOLING COMPONENTS

Hasco has several new cooling items, including double-sided hose nipples to connect two hoses, adapter couplings to connect U.S. and Hasco standards, and a HT (high-temperature) range of components with seals designed to withstand long-term exposure at up to 250 C/482 F for molding high-performance engineering resins.

DMS has a new compact, modular water manifold, and ifw mould tec is claiming to reduce cycle times by up to 20% with its new Xpress Cooling System (XCS), a conformal cooling approach applicable to both cores and cavities.

For higher PET preform molding productivity, MHT offers the new coolMax cooling plate, which is water cooled, so that air is cooled before it enters the preforms on the cooling pins projecting from the plate. Air enters the preforms and then leaves through the inside of the pins for more efficient cooling. Cooling air flow is divided, with one stream directed at the threads.

NEWS FROM MOLDMAKERS

Rotating stack molds for multi-component molding will make an impression at the show. One from Zahoransky has moving side plates to utilize all four faces of a “cube” mold on each cycle (see NPE Injection Molding article). And MGS Mfg. Group (mgstech.com) partnered with Gram Technology, ALBA/Thermoplay, and others to provide a dual-spindle rotary-stack, two-shot system for injecting 32 buttons with TPU and PC. The system will run in KraussMaffei’s booth and will use MGS’s Universal Multishot secondary injector for the PC.

Austrian moldmaker Haidlmair will show off its solution for molding plastic pallets of PP with TPE non-slip pads on top and bottom. The difficulty was in combining 18,000 cc of PP with just 129 cc of TPE on top and 86 cc on the bottom. It runs in a 3200-ton Engel two-platen press. The PP is injected through 10 hot-runner nozzles. The TPE comes from two small injectors mounted one on each mold half. They feed separate hot runners with nine and four nozzles.

After injecting the PP, the mold opens in two steps—first by 2 mm on the fixed side and then by 2 mm on the moving side. Each movement allows for injection of thin TPE pads on one side of the mold. TPE injection extends the cycle only from 90 to 110 sec.

NyproMold Inc., the giant global custom molder’s moldmaking arm, is exhibiting at NPE as a separate business for the first time. It recently added CT-scanning capabilities to its metrology services. It provides fast, precise 3D representations of molded parts both internally and externally in a nondestructive fashion.

MOLD SIMULATION ADVANCES

Autodesk Moldflow will release its 2012 updates this month, so no details were available at press time. However, two other suppliers of injection molding simulation software revealed enhancements that will be on display in Orlando.

Sigma Plastic Services, Inc. will be highlighting features of its Sigmasoft “finite-volume” simulation, including ability to accurately simulate LSR molding and to reliably predict mold temperature.

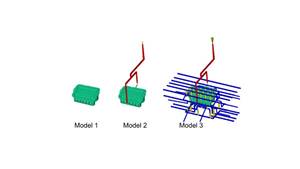

Coretech System will demonstrate the new R.11.0 of Moldex3D simulation software, released last December. Besides improved accuracy and efficiency, new abilities include simulating MuCell microcellular foaming and conformal cooling.

There’s also new Moldex3D Cloud Services, which lets users avoid buying powerful computers and software licenses. Instead, the simulation runs on remote computers and results are downloaded back to the user. The pay-per-use method is particularly beneficial to small and medium-size users. (Moldflow also recently launched cloud computing services—see Nov. ’11 Close Up.

Related Content

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More