At press time prior to the big show, several suppliers of tools and hot-runner technologies offered Plastics Technology a sneak peek at their plans for the show. Here is what we found:

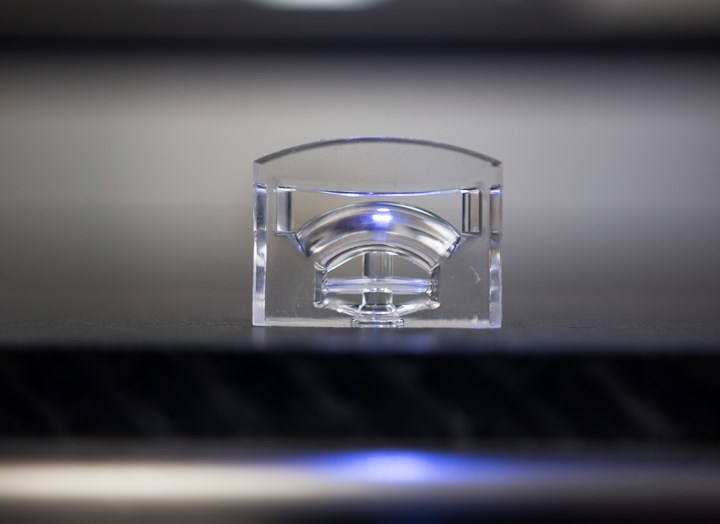

Husky Injection Molding Systems will show its new NexPET Mold, which it describes as a flexible mid-volume PET preform tool for shorter production runs and frequent changeovers. In hot runners and controllers, Husky’s display will include Ultra Helix 250 T2 valve gates. Husky says these are designed to improve part quality by maintaining superior gate quality for millions of cycles for small parts with difficult-to-access gate locations. On the control side, Husky will display the latest family of its Altanium Mold Controllers. Husky says these provide highly accurate temperature management with integrated servo-motion and valve-gate controls. Husky will also introduce its new online spare-parts ordering portal, which will be available for a demonstration on the booth.

Husky’s Ultra Helix valve gate hot runners promise superior gate quality in hard-to-gate parts.

Meusburger Georg GmbH & Co. KG will use K to launch its entry into cavity-pressure measurement, adding these sensors to its standardized lines of products for temperature, mold-closing force, and end-position control. Two products—E 6740 and E 6750—are included in the launch, the former for direct measurement and the latter for indirect measurement.

Meusburger notes that these are compatible with all piezoelectric pressure sensors and they are delivered with mounting accessories and connection cables available from stock with CAD data download from Meusburger’s online shop. The E 6740 cavity-pressure sensor for direct measurement is inserted directly into the cavity, while the E 6750 cavity-pressure sensor for indirect measurement measures cavity pressure via a force sensor located outside the cavity. Cavity pressure is transmitted to the sensor via an ejector pin.

Cold Jet will highlight its newest dry-ice blasting machine for cleaning molds and other components. The new PCS 60 features Cold Jet’s patented Particle Control System (PCS), which cuts dry ice into diamond-shaped particles ranging in size from 3 to 0.3 mm. The size is set by the operator. In addition to cleaning mold and machine components, the PCS 60 can also clean plastic parts before painting.

Cold Jet’s patented Particle Control System (PCS) cuts dry ice into diamond-shaped particles in 30 discrete sizes.

The PCS 60 has a 7-in. LCD color screen and digital controls, including the ability to program password-protected application recipes. With this feature, users can set and save blasting parameters, such as blast pressure, particle size and feed rate, for a particular job. (For more, see August Keeping Up.)

Hasco is announcing the supply of native data for CimatronE so that customers and designers can retrieve technical data for more than 100,000 products in Hasco’s portfolio from the company’s website, including the corresponding 3D data records for different CAD programs. Hasco says this updated native data for the CimatronE CAD system, allows parametric data to be integrated directly into CAD without the need for an exchange format, which can cause data loss. Hasco’s data library has been updated for CimatronE, Version 13.0, including numerous optimizations. Among these is expansion of the ejector range, integration of all Hasco products, and standardization of product names and designations. This new Hasco native database—Cimatron V1 2019/05—will be available for free download at the company’s website.

Hasco’s Z960 and Z9610 spiral cores allow cooling along the bore wall.

On the component side, the company is introducing new brass spiral cores. The Z960 and Z9610 spiral cores allow cooling along the bore wall for optimum temperature control. The single- and double-threaded versions are made from brass, which provides corrosion resistance and suits the components to use with water, steam, oil and air. The single-threaded model, Z960, can be used in parallel circuits, while the Z9610 double-threaded spiral cores can be run in series. The cores are temperature resistant to 250° C and are compatible with the prior Z96 and Z961 lines.

Burger & Brown Engineering is introducing its Smartflow TracerVMA electronic flowmeter with automatic flow regulation to the European market. It debuted at NPE2018. The automatic version of the meter modulates the opening of the connected flow regulator according to target flow rate or Reynolds Number input by the user. Automatic flow regulation (AutoReg) is able to compensate for changes in cooling-water line pressure, which occur during normal production due to press startups or shutdowns.

Burger & Brown’s TracerVMA with AutoReg can be connected to data acquisition systems or PLCs to give molders real-time statistical process temperature and flow data.

The TracerVMA with AutoReg can also be connected to data-acquisition systems or PLCs, giving molders real-time statistical process temperature and flow data. Since it monitors cooling-water conditions, it can be used in lights-out molding or sectors like medical, which require process validation. English or metric units are available for the system, which can track flow rates from 1 to 15 liters/min through 10 to 200 L/min at operating temperatures up to 120° C. Sizes from 3/8 in. through 1 in. NPT and BSPP are available.

Milacron’s Mold-Masters division will show its SeVG+ advanced valve-gate control system, which is now available for all applications. The servo-driven system controls individual valve-pin opening and closing profiles, giving molders the ability to adjust pin position, acceleration, velocity, stroke, timing and sequence. Each SeVG+ system includes an SeVG+ controller, with touchscreen display.

Each SeVG+ system from Mold-Masters includes an SeVG+ controller, featuring a touch-screen display.

Milacron’s DME division is introducing enhancement to its XPress mold base range, adding 25 additional steel grades, all of which are European certified through its “Any Shape, Any Steel” program, according to the company. DME has also expanded the range of its mold components to offer new varieties of standard leader pins, bushings, graphite guiding pins, insulating plates and centering rings. DME says it has also been registered with major designer software programs, including Topsolid, Siemens NX, and DS Catia to facilitate mold design.

Finally, DME will also showcase its new automatic device for cleaning, diagnostics and maintenance of mold cooling channels—CoolingCare. The new system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor. (For more, see June Close-Up.)

M.R. Mold will mold a high-beam automotive lens application from a two-cavity, three-plate LSR mold.

M.R. Mold will feature a two-cavity, three-plate LSR mold for a high-beam automotive lens application. The mold utilizes M.R. Mold’s 1-drop cold runner universal base, feeding two parts. An end-of-arm-tool assists demolding the parts to a robot that will remove it from the tool. Also in LSR tooling, Zahoransky USA Inc. (West Chicago, Ill.) will feature an LSR over mold thermoplastic tool featuring automation.

Germany’s Heitec Hot Runner Systems, which are marketed in North America via Technoject Machinery, is displaying a variety of hot runners, including its Flex-In and compact cam system. The new Flex-In system allows hot-runner installation in minutes without wire and nozzle assembly; a solid cable channel makes the assembly robust, according to Heitec.

The company says this design eliminates any possibility of incorrect wiring or installation, while also reducing the system’s stack height, since a nozzle retainer plate is no longer required.

StackTeck Systems Ltd. will showcase three of its precision, high-tech molds in action at K, running the molds in the booths of machinery manufacturers. These molds include low- and high-cavitation tools for round and rectangular containers featuring ultra-lightweight TRIM (Thin Recess Injection Molding) panels, as well as an in-mold labeling technology for a round thinwall lid. Static tool displays in the company’s booth will showcase a variety of technologies and applications, including PET preforms, servo-driven technology for different applications, co-injection, multi-material, specialty coating, KoolTrack and closure technologies.

Related Content

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreHasco Marks a Century in Mold Components, Mold Bases and Hot Runners with Cake and New Technologies

NPE2024: Cake, drinks and the unveiling of a new North American website providing online ordering in the U.S. and Canada for the first time are just some of the things happening at Hasco’s booth as it brings its year-long centennial celebration to Orlando.

Read MorePlate Design for Synchronous Valve Pin Movement

Heitec’s type 64.086 Syncro Plate for valve-gate systems, which is distributed in North America by Technoject Machinery, enables fully synchronous motion with valve-pin positioning accuracy down to 0.01 mm.

Read MoreHot Runner System for Commodity Resins

NPE2024: Mold-Masters’ EcoONE series hot runner system is optimized for processing commodity resins for simple, cost-sensitive applications.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More