Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Cables and plugs are a common source of hot-runner malfunctions. Here is a connector in which the pin in the upper left corner has been pushed in so that it won’t make proper contact.

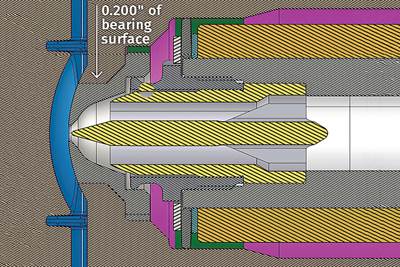

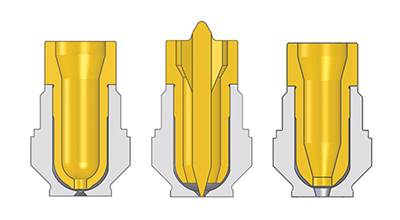

In part one of this series I discussed how hot runners have evolved dramatically over the past couple of decades. The sight of a hot-runner pocket pumped full of plastic is not as common as it was some years back. The biggest contributor to avoiding nightmares like the one shown below was when hot drops started being threaded to the manifold versus relying on the stack height, seal rings, and bolt patterns in the mold plates to hold the hot runner together.

Some toolmakers complained from a maintenance perspective that this was more difficult to work on when the drops had to be removed. In some cases this was true, with threads getting galled up and creating another mess. But improved thread designs and coatings have reduced this concern for toolmakers. So in the big picture of hot-runner issues, this has been a big improvement from my viewpoint.

Many toolmakers are hesitant to work on hot runners. The sight of numerous wires from the thermocouples and heaters can be intimidating. But in reality hot-runner systems are very simple in design, function and wiring.

I’d like to add a note here about adequate support of the hot half. I have observed some problems in this area over the years, but less so recently. If the areas cleared out for the hot runner are large, just consider ensuring adequate support to reduce the chances of deflection from cavity pressure. I got into a bit more detail on support and deflection in my columns on flash free molding (Oct.-Nov. ’14).

It is also very important when disassembling hot runners to follow proper procedures in removing drops and tips to prevent damage to threads. Proper preheat and torque specs must be followed, especially by less experienced personnel. Fortunately, in most cases of hot-runner repairs to clear blockage or replace heaters or thermocouples, the drop does not need to be removed at all.

HEATERS & THERMOCOUPLES

I have also observed that many toolmakers are hesitant to work on hot runners. The sight of numerous wires from the thermocouples and heaters can be intimidating. But in reality hot-runner systems are very simple in design, function and wiring.

Hot runners have zones, typically identified numerically, which are independently controlled with a heater and a thermocouple. It is important to have the wires labeled for each zone so it is easier to troubleshoot versus having to chase wires down among multiple zones. A hot-runner schematic should be kept on the side of the tool showing each zone location and the heater wattage.

The power plug/connection and the thermocouple plug/connection are also identified by zones. So, for example, the zone 1 heater leads would be to zone 1 on the power plug and the thermocouple to zone 1 on the thermocouple plug. The two wires coming off the heater are the same, but on the thermocouple they are not. The thermocouple has a positive and negative wire that must be connected to the correct locations on the plug or it will not function properly. Similar to the Plus and Minus poles on your car battery, it’s not complicated but will not work if the wires are reversed.

Thermocouples come in different types, but in all my experience I have encountered only the J type with the red and white wires. The white wire is positive and magnetic and the red one is negative. If you are ever in question which one is the positive wire you can use a magnet to find out which one is the positive. There are other thermocouple types that use different colors and will not work properly if your controller is not compatible with them.

I do not recommend adding wire extensions to thermocouples unless you are experienced with proper methods. Any heater and thermocouple connections with extensions must be insulated.

Nasty hot-runner leaks like this are a less common sight than they once were. Threaded nozzles are a big reason.

There are some actions you can take to troubleshoot hot runners in the molding machine rather than pulling the mold. One thing I recommend when having hot-runner issues is to change out the cables and controller to take them off the list. Many times I have found the controller or cables to have been the issue. And check the pins in the plugs—at times they can get pushed in so they are not making contact in the cable plug.

Also, keep in mind that just because the controller shows a zone at the proper temperature does not necessarily mean that it is actually at that temperature. I use a pyrometer with a 0.040-0.060 in. diam. sheath thermocouple to verify temperatures inside the hot drops or the inlet channel. When verifying temperatures in valve gates, pull the valve pin back to get inside the nozzle flow channel. I gently move the thermocouple back and forth against the steel in the flow channel to get an accurate temperature.

You need to get actual contact with the steel and will get a false reading if you just probe inside the drop, because the plastic will form a skin on the flow channel, which will affect the temperature reading.

When having hot-runner problems, I recommended changing out the cables and controller, which I have often found to be the source of the problem.

If you find you have a thermocouple issue and are not getting the proper set temperature, most controllers give you the option of running on percentage power output. If you have a matching zone with the same wattage heater, you can set the power percentage to match the amperage draw of the matching zone. You must also consider that the amp draw will change as you are running parts, because the heater will not have to work as hard with hot plastic running through the hot runner.

If you have a zone hotter than the setpoint on the controller, it more than likely is a thermocouple issue. If the thermocouple is loose or not making steel contact with the hot runner or hot drop, it will be reading the air temperature, which would be cooler than the steel of the hot runner. Thus, it is telling the controller the heater needs more amps, leading to a much higher zone temperature than the setpoint on the controller.

CHECK HEATER RESISTANCE

Heaters are in most cases like a light bulb—either live or dead. But in rare situations, damaged wires with some of the strands broken may not be able to handle all the amps required to bring the heater up to temperature. Heaters can be checked for proper resistance using a multimeter in the ohms setting. If you know the voltage and the watts on the heater you can calculate what ohms that heater should be reading (volts squared divided by the watts to get ohms). For example if you have a 240V heater with 1000W, the ohms should read 57.6 (240 x 240/1000).

Water leaks where water gets down into the hot-runner system can also cause problems. With most hot-runner designs today, this is not apt to cause major issues with blown heaters like it would with older designs. In most cases you just need to drain the water and dry the system out and put it back in operation. One sign of a water leak is when zones are struggling or failing to get up to the set temperature.

About the Author

Randy Kerkstra has been in the plastics industry for more than 26 years, occupied frequently with troubleshooting injection molding. When this was originally published he was working for a molder. Along with Steve Brammer he wrote the Injection Molding Advanced Troublshooting Guide, published by Hanser.

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreRead Next

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreHot Runners: A View from the Bottom Up

Addressing hot-runner benefits, improvements, and everyday issues from the perspective of decades of experience with probably every brand on the market. Part 1 of 2.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More