Mold Tracking, Simplified Cooling Line Coupling and More

NPE2024: Hasco, which marks its 100th anniversary in 2024, highlights multiple product lines making their U.S. show debut, as well as a revamped responsive website that simplifies online ordering.

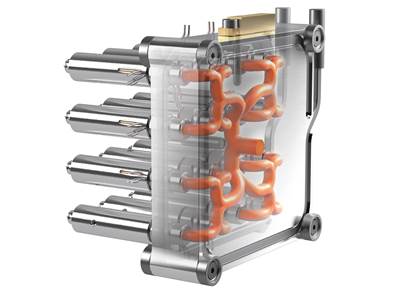

Hasco’s multicoupling system now features new U.S. (ZI) and French (FRA) systems that are available as open or closed versions with valves. The company also now offers the clean-break multicoupling system exclusively as an HT version with flat-sealing front surfaces to prevent cooling fluid leaking during decoupling.

Enabling the central connection of several cooling circuits in a single step, Hasco says setup can be carried out with only one lever, while eliminating the risk of mixing up the different cooling circuits and hoses.

The temperature resistance of the multicouplings can be increased to 180°C with water applications, with the full range offering 60 products, each with three model series. Plates are available with six, 12 and 20 connections. Couplings can be replaced without dismantling the hoses, and the modular structure enables individual configuration as well as integration into existing systems.

Hasco’s Mold Track System offers precise indoor localization technology for injection molds. Key to the product’s accuracy are ultrabroadband radio modules and the intelligent software platform, which result in location accuracy to within a few centimeters.

The system enables pinpoint tracking of molds in real time, as well as the digital interlinking of processes. Production delays resulting from misplaced tools are eliminated, with improved production planning and optimized use of active tools, as well as long-term tracking of idled molds.

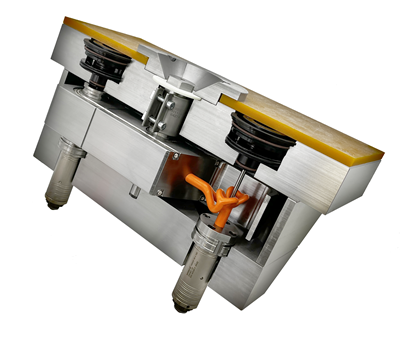

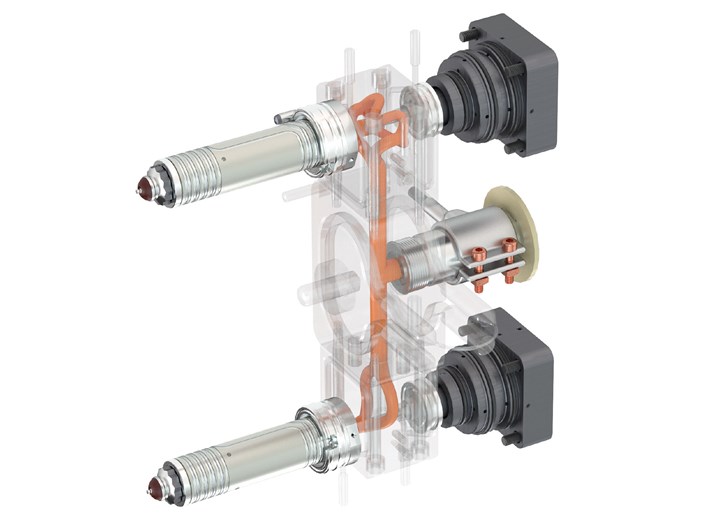

In hot runners, Hasco’s Streamrunner Shadowfree line, which feature 3D-printed manifolds, eliminates ‘shadow formations’ behind valve pins or areas of poor flow where material can collect and degrade. In traditional systems, areas of poor flow in the hotrunner can cause flow disruptions around the valve pin. These ‘shadows’ can lead to plastic degradation and challenging color changes. Streamrunner Shadowfree divides the material flow into streamlined channels, reuniting them where the valve pin enters the melt channel. Hasco says testing has demonstrated the ability to achieve rapid black-to-white material transitions in just 25 cycles. In addition to eliminating dead spots, Hasco says the Streamruner Shadowfree provides gentle material flow and a marked reduction in pressure losses, as well as smoother processing of heat-sensitive resins.

Hasco’s Streamrunner Shadowfree line features 3D-printed manifolds. Source: Hasco

New Website

Hasco, which has a portfolio of more than 100,000 products, has optimized its website including shifting to a responsive design, which is easily viewable on an array of devices regardless of screen size, including mobile devices.

The site features a slimmed-down, user-friendly menu navigation, with information, products and services available in 16 languages. Molds can be calculated, configured and directly ordered around the clock with a few clicks, and the mold base assistant can help users simplify and speed up processes, including the ability to configure a mold in five steps.

Information on product availability can be called up live, and the customized costing system generates parts lists and helps complete orders. CAD data can be downloaded quickly via interfaces into more than 40 different data formats, and CAD direct insert drivers import 3D data into a wide variety of different CAD systems. The export of parts lists for cost calculation and ordering has also been simplified. All customer-specific information can be called up in customer account, with inquiries and orders shown in full in the overview, which also displays the processing status.

Related Content

The Impact of Hydraulics on Tool Design, Practical Uses -- Part 2 of 2

Here are more tips on using hydraulically actuated devices on your tools.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreRead Next

Hasco Mold Trackers Provide Pinpoint Tracking of Injection Molding Tools

Hasco says its Mold Track’s ultrabroadband radio modules and intelligent software platform provide tool location accuracy down to a few centimeters.

Read More3D-Printed Hot Runner Manifold

The additive manufactured Streamrunner hot runner system from Hasco eliminates sharp corners for improved melt flow.

Read MoreFakuma 2023: 3D-Printed Manifold Eliminates Dead Spots Behind Valve Pins

Hasco’s new Streamrunner Shadowfree 3D-printed hot runner manifold is said to eliminate areas of poor flow behind valve pins.

Read More