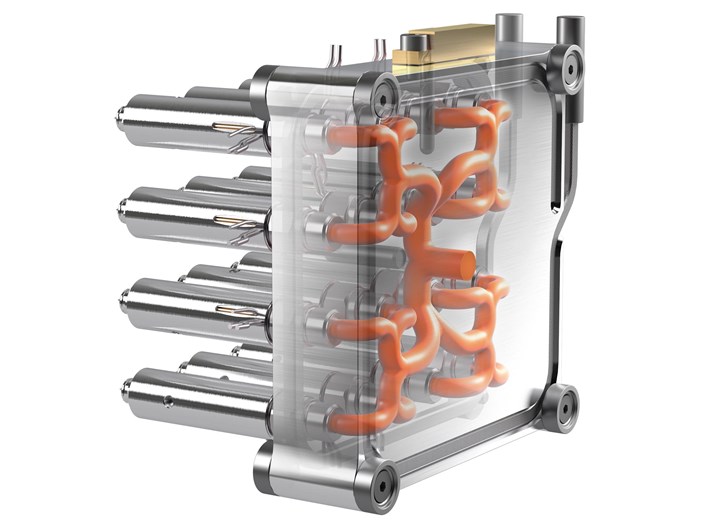

3D-Printed Hot Runner Manifold

The additive manufactured Streamrunner hot runner system from Hasco eliminates sharp corners for improved melt flow.

Previewed at K 2019, and now called the Streamrunner, the new hot runner systems from Hasco feature a 3D-printed manifold, granting molders greater design freedom. In a release, the company noted that it began investigating additive manufacturing as a means to fabricate hot runner manifolds back in 2016. Since then, Hasco says it has undertaken numerous studies and tests. Hasco said the official market launch at K 2019 generated strong interest, and since the show, there has been “a number” of successful customer projects using the technology, which the company has now dubbed Streamrunner.

By using additive manufacturing to create the hot runner manifold, Hasco says it can offer maximum design freedom. Flow channels can be configured with the optimum rheological layout, avoiding sharp edges, corners and areas with poor flow. By creating a smooth route for the melt through the manifold, the melt experiences much lower shear stress. Flow-optimized design also speeds up color changes, since the melt can be divided and deflected over larger radii.

Hasco says the complete absence of diverting elements allows the Streamrunner to be produced with a compact design, with a height of 26 mm. Tight spacing down to 18 mm is possible for high-cavity systems, depending on the application. Hasco says it can configure specific solutions tailored to individual applications on the basis of simulation analyses.

A Hasco spokesperson declined to identify the precise material that is used to fabricate the manifold but did say that the mechanical properties of the printed material are at least equal to the company’s conventionally manufactured manifolds.

The machine that builds the Streamrunner manifolds currently has a maximum build size of 250 by 250 mm. By tilting the manifold, the Hasco spokesperson said slightly larger blocks could be built, but that can have downsides. In addition, a printing machine with a larger build area could be used but there is a “break even point”, and customers must weigh more smaller Streamrunners compared to one large unit. Post printing, the manifolds do require some finishing, given the rougher surface that results from printing a metal, but Hasco could not comment on how the manifolds are smoothed out.

Hasco’s Streamrunner hot runner systems feature a 3D-printed manifold.

Related Content

-

Getting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.