TOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

NPE2012 News Wrap-Up: Tooling

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts. New hot runners were, of course, abundantly evident, with developments targeting especially valve gates and sequence controllers, as well as multi-tip edge and side gates. As always, much of the news concerned tighter nozzle spacing, better temperature control, and easier maintenance.

A special area of interest at this show was hot-runner nozzles for coinjection of barrier packaging, with two new entries—one of them claimed to be a world first. There was also plenty of news in standard mold components, preassembled systems, and cooling components. To get a full picture of the news, see also our March show preview, which included developments not repeated here.

FIRST COINJECTION STACK MOLD

Kortec Inc., (kortec.com) claimed a world first for the implementation of a multi-layer coinjection system using a stack mold. In production since March, the system molds 64 barrier food tubs of PP/EVOH/PP in a 2 x 32 stack mold from StackTeck (stackteck.com). Kortec supplied the complete system, which includes an 800-ton Husky Hylectric hybrid press. It runs on a 7.5-sec cycle, producting more than 200 million containers/yr. (Incidentally, Kortec recently moved from Ipswich, Mass., to a 30% larger facility in nearby Rowley, Mass.)

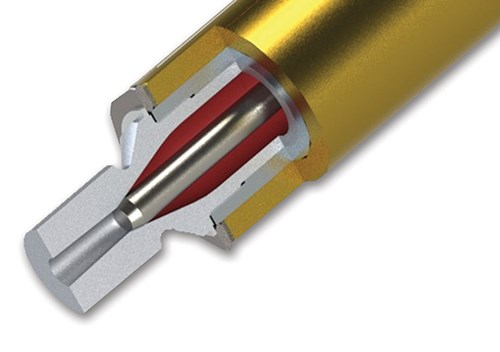

New competition in barrier coinjection technology for packaging appeared at NPE from Mold-Masters (moldmasters.com). Its new IRIS compact coinjection nozzle was demonstrated in molding linerless, three-layer HDPE/EVOH/HDPE caps and a thin-wall, deep-draw (80-mm-tall) food container of PP/EVOH/PP. The cap contained 3-5% of barrier material and the container less than 1 mil in a wall about 0.5 mm thick. IRIS technology comprises the nozzle plus Mold-Masters’ iFlow manifold technology to combine the melt streams and provide balanced fill; its E-Drive electric valve-gate control; and its M2 TempMaster hot-runner temperature control and mold-mounted E-Multi auxiliary injection unit located close to the gates.

The 38-mm cap was molded in 16 cavities at NPE on a 4.5-sec cycle. Mold-Masters said the cycle could be trimmed to 4.2 sec, of which only 0.2 sec is the coinjection time, and IRIS technology can accommodate 48 cavities. The tool was built by F&S Tool Inc. (fs-tool.com). Coinjection is controlled by direct sensing of melt pressure and temperature in the hot runner.

Mold-Masters says its IRIS nozzle is very compact—the same as a normal nozzle—and is very easy to service, allowing replacement of the tip, seal, and thermocouple as in a normal hot-runner nozzle. After molding, 100% inspection of the caps was performed by an IMDVista vision system from IMD Ltd. of Switzerland (imdvista.com). It uses proprietary non-visible wavelengths of light to check the thickness and location of the clear EVOH barrier layer.

VALVE-GATES RULE

Much of the action in hot runners at the show focused on valve-gate developments, including sequence controls. In addition to the news reported in March from Ewikon, ALBA Enterprises, Hasco America, Polyshot, and Synventive, here’s a quick rundown of other introductions:

•The new Zenith valve-gate system from DME (dme.net) is that company’s first standard valve-gate system of its own design. It comes in hydraulic or pneumatic versions and with nozzles 2 to 20 in. long. It works with DME’s new hydraulic valve-gate sequencer, which stores up to 32 recipes and 200 events.

•HRSFlow of Italy (div. of Inglass Spa, hrsflow.com) highlighted two new lines of valve-gate products. Multitech systems represent the company’s entry into caps and closures (it previously specialized in automotive). The system is designed for high cavitation, tight pitches, and fast cycles. Valve gates are springactuated. Valve pins can be adjusted from the clamping plate without disassembly. (Free-flow versions are also available.)

HRSFlow also introduced the new Diamond Lux Line of hot runners designed specifically for automotive headlamps and glazing (a specialty of Inglass). These valve-gate systems (also offered with free-flow open tip) have leak-proof, screw-in nozzles and are designed for very tight temperature tolerances (± 10°C across the manifold). The entire system is made of a special steel that reportedly minimizes degradation of PC resins, preventing black specks.

•Husky Injection Molding Systems (husky.ca) demonstrated its new Ultrasync-E electric plate-actuated valve gate, which allows minimum nozzle spacing of 18 mm. It ran a 0.35-g medical IV breather cap in a 64-drop system within an operating window of ± 0.002 g. The customer for this system had been using a cold runner (still common for very high-precision parts, Husky notes). With the switch to Ultrasync-E hot runner, the customer’s resin use dropped by half while cycle time shrank from 16 to 8 sec. The system has run in production for more than 3 million cycles with no adjustment and no wear on the gates, according to Husky, far exceeding the usual 500,000 cycles between valve-gate maintenance checks.

•Incoe Corp. (incoe.com) introduced a valve-gate tip with the VIX end cap designed specifically for fast color changes. Incoe also showed for the first time in North America its SoftGate valve-gate sequence control. It provides hydraulic control of pin velocity, providing precisely timed, gradual pin actuation in order to prevent a sudden drop in injection pressure and melt “hesitation,” which can cause flow lines in large automotive and appliance parts.

•Mastip of New Zealand (U.S. office in Slinger, Wis., mastip.com) has a new MVG-25 valve-gate nozzle for closer pitches—around 40 mm, vs. 55 mm before. It’s aimed at caps and closures.

•Mold Hotrunner Solutions (MHS) revealed more information about its new Rheo-Pro iVG back-to-back internal valve-gate nozzles for ultra-compact “short-stack” molds. Because of their compactness, such molds can be run in smaller presses. For example, a 48+48 stack mold for lightweight bottle caps measures only 285 mm face to face, so it can run in a 200-ton press. That means over 50% energy savings vs. a 96-cavity single-face mold running in a larger press and on a longer cycle. What’s more, the internal valve gates need no seals, no lubricant, and no maintenance, according to MHS (moldhotrunnersolutions.com). They are fully accessible from the parting line and are air actuated through the manifold.

MHS exhibited one of the smallest valve-gated parts—a 3-mg PP micro-gear molded in 32 cavities on a 5-sec cycle, which includes takeout to cavity-separation tubes and camera inspection of the mold face to spot any stuck parts.

MHS also showed a 700-mg HIPS syringe plunger from a 128-cavity valve-gated tool with 18-mm gate pitch. The tool has run 2 million cycles without maintenance and is not due for maintenance until next year.

•Mold-Masters now offers its E-drive servo valve gates in larger sizes for automotive and large appliance parts. An example is the new EVH 110 (110 mm).

•Osco (oscosystems.com) introduced a low-cost valve-gate sequencer that is compact and portable from machine to machine. It costs only $2850 for controlling up to 8 gates.

•New from Yudo (yudo.com) is the SPICon hydraulic speed control for valve gates, designed to control turbulent flow of melt into the cavities. There’s also the new TW 700 handheld temperature and sequence control for up to 8 gates. In addition, Yudo’s Yuri II front-mounted valve-gate nozzles have their actuation up front so there is no extra height. Valve-pin operation is said to be free from influence by manifold thermal expansion.

MORE NEW NOZZLES

Cluster nozzles for hot-runner edge gating and side gating were another theme at NPE. Husky’s new Ultra SideGate for up to four cavities from a single nozzle is said to provide a wider operating window without leaks for deep-draw parts like pipettes, syringe barrels, and other parts requiring minimal gate vestige. Spring loading reportedly keeps the gate centered on the cavities despite thermal expansion.

Incoe added edge-gate nozzles to its Direct-Flo Gold series. Aimed at medical vials, syringes, and pipettes, the nozzles provide up to eight tips with a titanium-aluminum coating of 70 Rc hardness for extra durability. They feature quick-disconnect wiring and can incorporate Incoe’s exclusive Opti-Flo rheologically balanced manifolds utilizing Beaumont Melt Flipper technology. Opti-Flo reportedly eliminates core shift for straighter parts.

As reported in March, Mold-Masters demonstrated its new Melt Cube linear side-gating system in molding 16 small (5-cc) syringes with in-mold labeling (IML) at the CBW Automation booth (cbwautomation.com). “Edge gating with IML breaks the rules,” noted Mold-Masters CEO Bill Barker. He said this accomplishment was possible with “considerable engineering” by the moldmaker, Tech Mold (techmold.com).

Mold-Masters also introduced its new Vision line of angled systems for automotive lenses. Most of the system has been standardized for fast delivery and low cost.

New from Mastip is the long-life G2 tip designed to resist wear in millions of shots of unfilled materials.

Osco introduced hot runners said to be unusual in that they are small enough to fit MUD molds. These offer up to eight gates within a 2-in. circle.

Yudo brought out its WINA “premium” nozzles for engineering resins, clear materials, and high-temperature or heat-sensitive grades. There’s even a micro version for parts such as 0.1-g PEEK dental drill components or LED lead frames, connectors, and camera parts. The company also upgraded its general-purpose BALA nozzle line.

HOT RUNNER FOR STRETCH-BLOW

Mold-Masters has staked out new territory by establishing its Axiom hot-runner system in single-stage (all-in-one) PET injection stretch-blow molding (ISBM). Axiom technology incorporates Mold-Masters’ IFlow manifold design, valve disk, and brazed nozzles, as well as specially designed liners and seals and a sealing device to protect the valve actuator from PET dust, which reportedly has been a chronic issue with other systems. Several Axiom systems have been sold. They reportedly provide resin savings, shorter cycles, increased uptime, superior bottle and gate quality, and fast, simple startups.

PREASSEMBLED HOT RUNNERS

Preassembled, prewired hot-runner systems as a lower-cost alternative to a complete hot-half were presented by several exhibitors, such as Osco and Synventive, as reported in our March preview. In addition, DME announced new unitized valve-gate systems, and Yudo showed off its Eco Modu preassembled systems for the automotive market (it also offers hot halves).

HOT-RUNNER TEMPERATURE CONTROLS

Several exhibitors announced new hot-runner temperature controls:

•Athena Controls, Inc. (athenacontrols.com) showed the Bedros controller for medium-sized applications (8 to 32 zones). It offers 15 amps/zone, touchscreen, built-in buttons for joystick operation, naming of zone groups for quick selection and configuration, ability to export setups to flash drives, and an overview screen that summarizes all zones’ setpoints, actual values, and alarms.

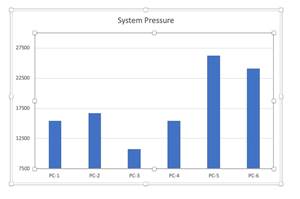

•New G24 controller from Gammaflux L.P. (gammaflux.com) combines aspects of the company’s LEC and TTC controls while making it smaller, faster, less expensive, and easier to use. It handles up to 24 zones per control block with 15 amps/zone. A 128-zone G24 controller has a 48% smaller footprint than a comparable TTC unit. The company’s “most affordable controller yet” boasts a 0.1-sec screen update time, improved machine interlocks, improved leak detection, and Mold Doctor automated troubleshooting software.

•Husky plans to introduce later this year the next version of its Altanium Matrix controller, which will have larger capacity and will include control of cooling-water flow in addition to electrical heating of nozzles and manifolds.

•Mold-Masters introduced a compact mid-range controller, the TempMaster M1. Two models handle up to 24 or 48 zones, using 6-zone control cards with 15 amps/zone. It has a color touchscreen with adjustable viewing angle.

•Yudo has upgraded its CW 991 controller for up to 240 zones (in increments of 6). This PC-based unit has a touchscreen and comes in standard and “slim” versions, as well as a low-voltage model for very small and sensitive parts.

TOOLING PRODUCTS FOR OEMs

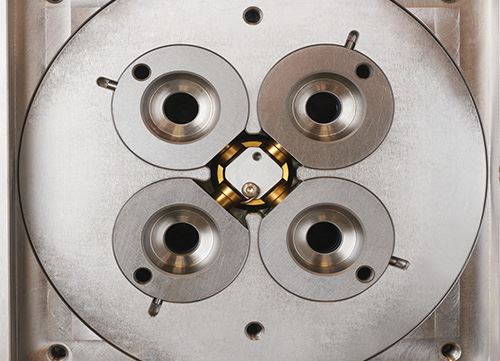

Roehr Tool Corp. (roehrtool.com) showed off its four-cavity ProtoBridge Tool designed to help OEMs and moldmakers reduce product development costs. This compact, pre-engineered mold system uses Roehr’s Dove Tail collapsible cores to develop caps and closures with internal undercuts. It can be converted from one part design to another while still in the press and avoids constructing dedicated mold bases for every new product. Available for rent or purchase, the tool comes in two sizes that cover cap diameters from 0.675 to 2 in.

AST Technology GmbH (ast-tech.de), a sister company of Roehr Tool within the PCIC Group, offers a new way for OEMs to keep track of production at multiple molders. Program Watch helps the OEM determine that a program is on target for production, productivity, and mold maintenance. Program Watch uses AST’s CVe Monitor installed on the mold to keep track of total cycles, cycle times, uptime, and maintenance on each tool at custom molders or contract manufacturers. This data is uploaded from the CVe Monitor to AST, which compiles a monthly report that is emailed to the OEM.

NEW MOLD COMPONENTS

In addition to the new standard components mentioned in our March NPE preview, Progressive Components and DME Co. brought out several more at the show. Progressive (procomps.com) introduced Z-Series alignment locks that are said to far outlast others on the market, confirmed by independent lab testing and monitoring in real-world conditions. They come in guide lock, side lock, and top lock styles with special features to maintain clean and consistent lubrication.

Also new is the DT core-retention sleeve from sister company Roehr Tool. For use with collapsible cores, it protects molded parts from damage during ejection. The steel sleeve prevents parts from sticking to a segment of the collapsing core, which can pinch or cut the part. The retention sleeve, integrated into the c-core or the mold plate, avoids the need for more costly solutions like three-stage ejection or using a robot arm to support the part before ejection. In slide applications, retention sleeves can shut off on the solid sleeves instead of c-core segments.

DME launched standard slides in a wide range of sizes at NPE. Also, its new Vortex core pins and plugs offer cost-effective venting of cavities. These components are made of Porcerax II porous sintered metal, which is 25% void space by volume. It vents gases without need for separate venting components. In March, we also previewed new components from Hasco, DMS, and ifw mould tec.

FOR MOLD COOLING

A batch of new cooling components from Progressive Components includes the Bubbler Base, which accepts attachment of a thin-wall cascade tube and is designed for maximum coolant flow and ease of mold assembly/disassembly. It comes in two installation styles and four sizes. Also new are non-interchangeable Keyed Connect socket connectors and hose fittings for foolproof connection of cooling lines, plus new swivel-type water jumpers that can be installed within a mold plate instead of outside, and water-line safety clips for easy identification of blue and red water lines.

DME Molding Supplies introduced a line of digital scale control systems. These reportedly prevent and even remove scale deposits electronically by means of a coil surrounding the water pipe, which emits a complex pattern of frequencies.

(Other new cooling components from Hasco, DMS, and MHT were reported in our March preview.)

NEW REPAIR COURSE

ToolingDocs (toolingdocs.com), a center for mold-maintenance training, has introduced a new course on tooling component repair. It teaches how to rework worn edges, dings, scuffs, and scratches with laser welding, TIG welding, brazing, stoning, blueing, and polishing.

Related Content

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

Read MoreDesign Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreGet Better at Using Foam for Your Molded Parts

Machine performance and process speeds are critical when using foam to reduce part weight while retaining part integrity.

Read MoreRead Next

Tooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More