3D Printing’s Growing Presence Seen at Fakuma Show

Additive manufacturing appeared in tooling inserts, robot grippers, and molded parts.

Additive manufacturing, or 3D printing, appeared in various guises throughout October’s Fakuma 2015 show in Friedrichshafen, Germany. Arburg (U.S. office in Rocky Hill, Conn.) brought three of its Freeformer machines, the first to use standard molding pellets, to Fakuma. Two of them formed part of “Industry 4.0” exhibits of “personalized manufacturing” in which the Freeformers applied individualized decoration to injection molded parts. One new wrinkle was an automated cell in which a Freeformer was tended by a Kuka robot instead of a human operator (see this month's Fakuma Close Up).

Arburg officials noted in a Q&A session with the press that its 3-axis Freeformer model is meeting current demands of the market and there is little push from customers so far to commercialize a more expensive 5-axis version. More immediate development priorities, the officials said, were nitrided components to resist wear, a larger build envelope, and printing of high-temperature resins.

While Arburg is the first plastics machinery company to offer its own 3D printer, Boy Machines (U.S. office in Exton, Pa.) announced at the show that it is offering a turnkey package with a Stratasys 3D printer for making plastic cavity inserts. Such tool inserts (which also appeared at multiple exhibits at NPE2015 in Orlando) are typically made of ABS and are said to last for up to 500 shots. Because there is no internal cooling for the inserts, Boy blew cold air over the mold face between cycles.

3D-printed ABS mold inserts were also shown at Fakuma by Hasco (U.S. office in Fletcher, N.C.) as prototyping accessories for its quick-change mold bases.

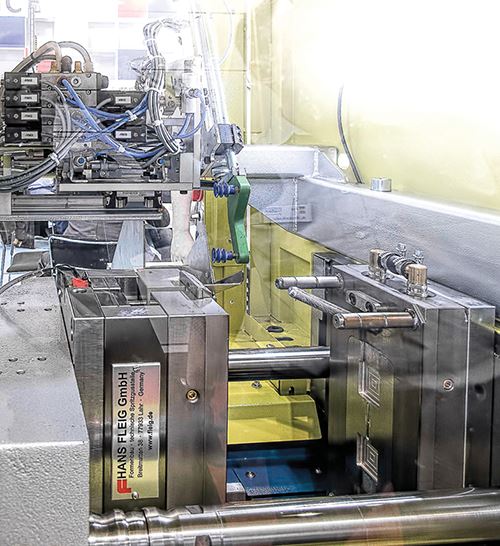

Boy Machines showed another application of 3D printing in end-of-arm tooling for a sprue picker (pictured here). KraussMaffei (U.S. office in Florence, Ky.) also showed 3D-printed EOAT on articulated six-axis and Cartesian three-axis robots, as well as a servo sprue picker, in three molding cells. KM noted that 3D printing allows the customer to make its own EOAT, to make it fast and lightweight and with optimized conformity to the shape of the part to be handled. (For more on 3D-printed EOAT, see Aug. ’14 Close Up.)

Related Content

-

Business Slowing? There's Still Plenty of Stuff to Do

There are things you may have put off when you were occupied with shipping parts to customers. Maybe it’s time to put some of them on the front burner.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.