News in Hot Runners & Tooling at K 2013

Close Up: Hot Runners & Tooling

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show.

Molds that break speed records for specific applications; hot runners for medical, packaging, and automotive parts; temperature and valve-gate controllers; and standardized mold components constitute a large grab-bag of news in the tooling category for injection molding at the Dusseldorf show. For a wider picture of news at K, see also our September preview and the roundup on injection molding last month, as well as the initial news report in December.

SETTING NEW SPEED BENCHMARKS

Billed as the fastest-running mold at the show, a 64-cavity tool from Otto Männer GmbH (U.S. office in Lawrenceville, Ga.) produced HDPE irrigation drippers on an Arburg Allrounder 470 A all-electric press (100 m.t.). These parts have extremely complex structures and weigh only 0.15 g (total shot weight is 9.6 g). Conformal mold cooling helped produce a cycle time of just 1.91 sec, for over 120,000 parts/hr or 500 million/yr.

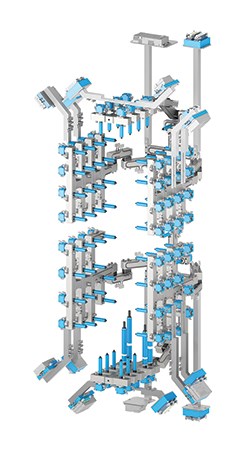

Moldmaker StackTeck Systems, Brampton, Ont., claimed two productivity advances at the show. One was a 2 x 8 stack mold running thinwall, 16-oz dairy containers at what was said to be an “unprecedented” cycle time of 3.3 sec. It ran on an Engel all-electric e-speed 650T press. And at the booth of Wave Swiss, a maker of injection machines, StackTeck ran its next-generation 1881 tamper-evident carbonated soft-drink cap mold with four cavities in 2.8 sec, cutting more than 1 sec off the previous speed. Cap weight was 2.15 g.

HOT-RUNNERS & CONTROLS

New from DME Co., Madison Heights, Mich., is the DME Intelligent Temperature Control System, offering compact footprint and plug-and-play compatibility with a wide range of hot-runner systems. It has a 5.7-in., fold-away color touchscreen and self-diagnostic testing capabilities to check each zone. The system is based on six-zone, 15A modules for up to 48 zones per controller.

The latest from Ewikon (U.S. office in Rockford, Ill.) is the HPS II-MV multi-tip valve-gate nozzle with two or four drops. The plate-actuated nozzle has 6-mm melt channels and minimum gate pitch of 13 mm. A special expansion groove milled between the tips is said to eliminate a common problem with multi-tip nozzles—radial thermal expansion causing compressive stress on the sealing surfaces, valve-pin deflection, and gate wear.

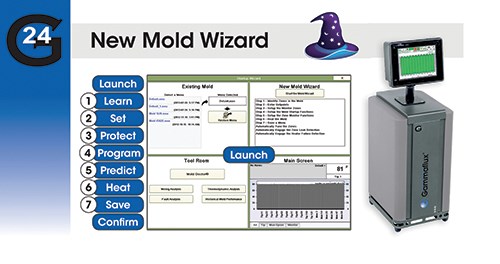

Gammaflux, Reston, Va., expanded its G24 line of temperature controllers with a 12-zone module for smaller hot-runner systems as an alternative to the existing 24-zone version. It’s available with the standard touchscreen interface or a new, lower-cost Mini touchscreen. The latter is Windows based and handles up to 48 zones. Also new for the G24 line is Mold Wizard software to ease setup and configuration. One thing the Wizard does is automatically activate the controller’s leak detection function, which many users ignore. It monitors both Volts and Amps, where as other leak detectors monitor only Amps, Gammaflux says. Detecting just one leak early reportedly can provide 100% payback and save weeks of lost production.

New developments from Gunther Hot Runner Technology in Germany (U.S. office in Hoffman Estates, Ill.) include new sizes of nozzles with Blue Flow heater technology, up to 250 mm long for 4-6 mm nozzles. Designed for sensitive resins, these nozzles offer heating adjustment in each section over the entire length of the nozzle. They also boast lower energy consumption and a slimmer profile. Blue Flow nozzles ultimately will be available in all sizes. Among other recent developments are improved cold-runner systems for LSR, OktaFlow linear multi-tip (up to four) side-gate nozzles with improved temperature control, and enhanced valve-gate systems (pneumatic or hydraulic) that now can read the pin’s open or closed positions.

Hasco’s Hot Runner Div. (U.S. office in Fletcher, N.C.) brought out a range of new products:

•Standardized hot-runner manifold blocks (H4000) offer a very wide range of layout options within standardized block dimensions. Hole distances for nozzles can be freely selected within defined limits. Manifolds are described as leak-free and have no sharp corners in the flow channels to minimize shear. Four basic configurations offer economy and short lead times.

•H4420 servo-electric valve-gate actuator (H4420) comes with a compact touchpanel controller that monitors and adjusts needle force and position for each cycle. Two servo drives (instead of the usual one) are supplied with an actuator plate to provide ample force. Setup memory functions for individual molds and USB port are included.

•Larger (15-in.) color touchscreen monitor is new for the Z12402 process monitor (up to 64 zones).

•Powder-coated luminum wiring boxes (Z13100) replace plastic cases for added durability

•Techni Shot nozzle series Type 20 for small shot weights gains new nozzle lengths of 100 and 125 mm. Type 20 nozzles are now also available as needle valves with gate diameters of 0.8 mm and larger. New bronze heaters for these small units are said to provide smoother temperature profiles.

As previewed in September, HRSflow of Italy (N. American office in Windsor, Ont.) showcased its new FlexFlow electric valve-gate system with independent servo control of speed, force, and position for each valve pin to prevent hesitation and flow lines. It has a touchscreen controller.

Incoe Corp., Troy, Mich., showed off its new HEM compact hydraulic actuator for valve gates. With about 50% smaller footprint than standard hydraulic cylinders, HEM units allow closer spacing and higher cavitation without resorting to less powerful pneumatic cylinders. Closer gate pitch can also be advantageous in large automotive molds that require large hot-runner systems.

Männer introduced a new side-injection valve gate for syringes molded of cyclic olefin copolymer (COC). Up to now, this glass-clear resin has been molded with open-tip nozzles, often resulting in black specks because the COC is sensitive and burns easily, according to Männer. The company said it is hard to design such a small valve for side gating. Each nozzle can have from one to four tips.

A new configuration wizard for Männer’s HCS-TS 2 hot-runner temperature controller guides users through setup in only six steps.

Mastip Technology Ltd. of New Zealand (U.S. office in Singer, Wis.) brought out two new sizes of pneumatic valve-gate actuators, larger and smaller than its MVG40 model. All units handle a range of nozzle sizes. The larger unit, MGV55 (5-mm pin diam.), can be used with the company’s largest BX models with 12-mm flow channel. The smaller MGV25 has 2- to 2.5-mm pin diam.

Also new are Mastip’s TL35 screw-in nozzles with 12-18 mm flow channels for larger parts.

As reported in December, an unusual development from Mold Hotrunner Solutions (MHS), Georgetown, Ont., is the new Rheo-Pro Slide Manifold. It has hinged melt-transfer joints that allow linked manifolds to move freely in order to distribute plastic anywhere inside the mold—even directly inside moving slides and lifters. The technology enables a continuous melt path across moving mold elements that are necessary for demolding complex parts with exterior undercut side features like ribbing. This type of flexible manifold can be useful for stack molds, tandem molds, and rotary and cube molds, MHS says.

MHS also claims to have achieved a first for its new Black Box pneumatic valve-gate actuator for high-temperature applications. It can run at up to 400 C (650 F)—hotter than electric actuators can stand, MHS says—and it requires no seals, lubrication, or cooling. It’s suitable for clean-room applications and others that must run maintenance-free for millions of cycles.

New from Mold-Masters, Georgetown, Ont., are Accu-Valve MX valve-gate nozzles with dual pin guidance to maintain exact alignment for lasting gate quality. It combines the CX and EX nozzles into a single design that is warrantied for over 3 million cycles. It reportedly performs well with both commodity and engineering resins, suiting it to medical uses.

For carbonated-beverage closures, Mold-Masters has a new version of its Sprint hot-runner system that is faster, more compact, and uses less energy. Sprint 2.0 is running in production at less than 2 sec for a 96-cavity mold. Sprint also is now available for tighter pitches, down to 35 mm.

For automotive molding, Mold-Masters introduced the Fusion G2 F7000 nozzle up to 1000 mm long, now with field-replaceable heaters, new gate-seal styles, and redesigned wire channels for greater protection and easier front access.

Mold-Masters also launched the TempMaster iM2 temperature controller, which can be integrated into any injection machine. It offers a touchscreen with 3D graphics, a new Purge Wizard and energy monitor that shows kW/kg consumption for each shot.

As reported in our initial K Show news story in December, Thermoplay of Italy introduced hot sprue bushings made by laser sintering of powdered metal so as to incorporate conformal cooling. These bushings reportedly offer cycle-time reductions of up to 40% and improved dimensional control of molded parts with less shrinkage, warpage, and flow lines.

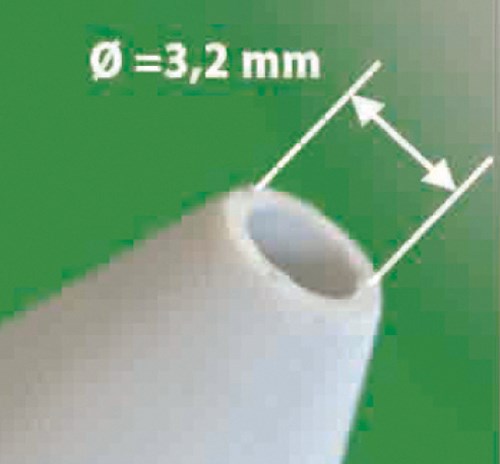

Another development from Thermoplay is a special multi-tip nozzle for tubular parts such as pen barrels that require multiple gates in restricted areas. This three-tipped nozzle provides axial direct injection with a minimum gate distance of 3.2 mm. The benefit is said to be balanced filling without core shift.

Thermoplay also showed its new FN open-nozzle family designed for high-temperature resins and to provide more uniform temperature with less energy consumption. It allows removal of the heater and thermocouple without removing the tip. The new bimetallic tips have increased contact area and low heat transfer; they can be used with older F series nozzles.

Thermoplay’s new line of single valve gates use the same tip as the FN nozzles. They have four smaller flow channels instead of one large one, for more uniform heating. A new feature allows different nozzle lengths and diameters to mount on the same head.

For large parts, Thermoplay has new screw-in nozzles up to 60-mm diam. with up to 25-mm flow bore and valve pins up to 10-mm diam.

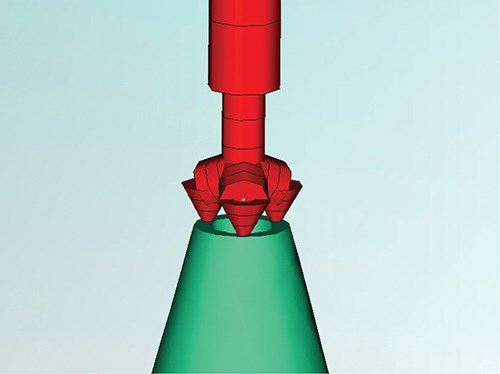

Yudo of Korea (U.S. office in Plains City, Ohio) offers a new Spicon sequential valve-gating control that regulates pressure to open the gates gradually avoid flow lines. It uses hydraulic actuation and encoders to regulate pin travel precisely.

Also new from Yudo is the Bold 3 hot-runner temperature controller, said to be more robust and simpler to operate. It comes in modules of 12 zones.

NEW MOLD COMPONENTS

According to Hasco, it is now possible for the very first time to have cooling channels in a mold cross each other on the same plane in a flexible and inexpensive manner. Hasco’s new Z99 CoolCross component permits a homogeneous temperature distribution at the mold core or insert, as well as constant cavity cooling on all four sides during the cycle. Made of nylon 66, the CoolCross insert incorporates a locking mechanism to prevent unintended rotation of the unit and blockage of cooling lines.

By allowing cooling channels to cross each other in the same plane, CoolCross reportedly allows for thinner plates and thus shorter nozzles and guidance and attachment elements. Fewer cooling channels can also result, since it is no longer necessary to separate crossing cooling channels in different planes, thereby reducing tool cost.

Hasco’s Mold Base Div. displayed a number of other new mold components; here’s a sampling:

•For short-run and prototype molding, the Clever Mold System (CMS) is a quick-change system where by the CMS mold base stays on the machine and only the cavity plates and ejector package are changed—in 5-10 min, even with a single-nozzle hot runner. It reduces the mold-base cost by around 30%. Adjustable clamping bars make it easy to clamp molds of different sizes. Unlike other quick-clamping systems, CMS is said to offer no restrictions on ejectors or other functions within the mold area.

•Z1215 thermal insulating sheets are useful for LSR molds.

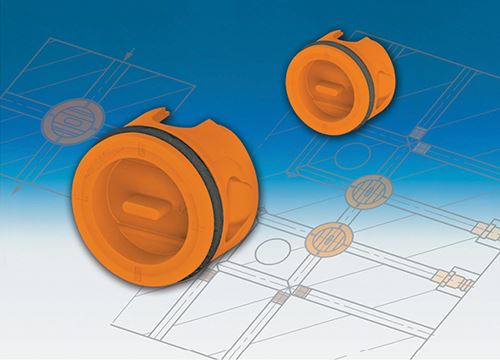

•Push-Lok coupling system for mold-cooling lines are quick connectors that require no tools or separate hose clips and ferrules. Hoses and couplings with blue or red ID rings come with or without a shutoff valve, and angled at 45° or 90°.

•Said to be a first, wear-resistant diamond-like coatings (DLC) are available on standard ejector sleeves (Z457) in the original outer dimensions (pre-ground to allow for the coating thickness). Latch locks are also available with DLC.

•A new angle pin with eccentric clamping disc (Z0102) eliminates the need to make deep threaded bores or bore holes through the cavity plate. The angle pin can be readily inserted or removed from the parting line of a mold mounted in a press. The pin and clamping disc are reusable and can also be used on existing molds.

•A new series of guidance and centering units were developed specially for high-precision molds. These include flat and round locating units and DLC-coated versions, as well as a DLC pre-locating unit.

Progressive Components, Wauconda, Ill., has made Z-Series alignment locks its new standard, replacing the black-and-gold line. A recent test report shows that Z-Series locks show no wear after 2 million cycles, while others fail after only 40,000 cycles.

Staubli (U.S. office in Duncan, S.C.) brought out two new tooling developments. One is a flat-face water coupling that is said to reduce leaks, making it suitable for clean rooms. Also, Staubli has increased the safety of its IMAG magnetic clamping system to automatically detect any movement of the mold and signal the machine to stop. Staubli is working with a machine builder to integrate the IMAG controller with the machine control. The system will read the magnetic force at each coil and if it detects any change, the machine automatically limits the opening force on the clamp. (For more news in magnetic clamping, see last month’s K report on injection molding.)

Related Content

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreHow to Design Three-Plate Molds: Part 5

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs. In this installment, the focus is on design and placement of sucker/puller pins.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

Read MoreK 2013 Preview: Injection Molding

Next month’s mammoth triennial plastics show in Düsseldorf, Germany, challenges injection molding machine builders to demonstrate technological leadership in addressing the needs of the marketplace.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More