Headlines from the K 2013 Show

Here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

- Additive Manufacturing

- Multicomponent

- LIM & LSR Molding

- Commodity Resins

- In-Mold Decorating

- Extrusion

- Stretch Blow Molding

- Tooling

- Engineering Resins

- Blow Molding

- polyolefins

- Processes

- Automotive

- Barrier Blow Molding

- End Markets

- Postprocessing

- Film Extrusion

- Processes

- Packaging

- Injection Molding

- Hot Runners

The world’s premiere exhibition of new plastics technology, a triennial event, took place over eight days in October in Düsseldorf, Germany. The K 2013 show brought together over 3200 exhibitors and 218,000 visitors to see the latest in processing machinery, materials, additives, and techniques. Four Plastics Technology editors scanned the 18 halls for news of interest to North American processors. Our full report will arrive next month. But here’s just a taste of the innovations on display, a selection of the top headlines not covered in our September show preview.

INJECTION MOLDING NEWS

One of the most dramatic announcements for injection molders at the show was not actually about injection molding. Arburg (U.S. office in Newington, Conn.) branched out in a new direction with its Freeformer additive manufacturing system, an inkjet-type 3D printer that builds up parts droplet by droplet in thin layers. Arburg is aiming this new machine squarely at its injection molding audience, offering them a new means to keep up with trends toward smaller batches and individualized products. The Freeformer is not so much for prototyping—which Arburg called “a thing of the past”—but to give molders new possibilities to make complex part geometries that cannot be injection molded and to allow them to produce economically in lots as small as one piece.

One striking innovation is that the Freeformer uses standard plastic pellets—almost any thermoplastic is said to be suitable, so long as it does not contain much filler or glass fiber, since the system uses a 0.2 mm orifice to dispense 0.3 mm droplets of melt. This not only allows processors to make fully functional parts from the wide range of commercial resins, but reduces material cost by up to a factor of 100, Arburg claims, by eliminating the need for special powder or filament raw materials.

The Freeformer uses a stationary vertical screw plasticator to melt the resin, which is dispensed under pressure through a stationary head at 100 droplets/sec using a piezoelectric system. The part is built up on a table that moves in three axes (standard) or five axes (optional). The latter has the advantage of allowing production of severe undercuts without support structures, saving material and secondary finishing operations. Maximum part size is 130 x 130 mm x 250 mm high. Build time for such a part is typically around 1 hr. Parts produced this way have no built-in stresses and reportedly achieve strengths about 70-80% of standard injection molded parts.

The Freeformer can use two melting and dispensing systems to make two-color or two-material (even hard/soft) parts. Colored materials can be used. Production is said to be free of dust or emissions, so that it can be used in any environment, even offices or clean medical production areas.

Like other additive manufacturing systems, the Freeformer takes CAD files in STL format and slices them into layers. A gesture-controlled multitouch screen reportedly makes it easy to use with no special programming or extensive training. “Just plug it in and start manufacturing,” Arburg says. The system is also very compact and fits through a standard doorway.

Price had not been set at show time, though it reportedly will be in the range of a high-end injection machine. The machine will be available next year.

Brand-new technologies are coming to injection molding itself. One is room-temperature UV curing of liquid silicone rubber (LSR) pioneered by Momentive Performance Materials, Waterford, N.Y. Benefits include faster cycles, especially with thick-wall parts, and ability to overmold LSR onto lower-cost thermoplastics such as PP rather than just higher-temperature engineering grades that can withstand LSR heat-cure temperatures. One of the questions about this technology has been how to expose the uncured silicone to UV light in the mold cavity.

At K 2013, Elmet of Austria (U.S. office in Lansing, Mich.) showed a novel solution at Momentive’s booth. Using an Engel e-mac electric press, Elmet supplied the LSR dosing system and mold (with the LSR mixhead mounted directly on the tool) for producing a PP soap dish with a non-slip silicone base. The hard PP dish was molded first and then transferred by a robot to a second cavity in the tool where it was overmolded on one side with LSR. The novelty was that in this second cavity, a clear plastic tool insert is clamped against one side of the PP part. Behind the clear insert was a UV lamp. Thus, the UV light was shone through the PP part to cure the silicone on the other side.

There was also lots of news in hot runners for thermoplastics at the show. Among the novelties was the use of conformal cooling in hot sprue bushings by Thermoplay of Italy. Made by laser sintering of powdered metal, the conformal-cooled bushings reportedly offer cycle-time reductions of up to 40% and improved dimensional control of molded parts with less shrinkage, warpage, and flow lines.

Also unusual is the new Rheo-Pro Slide Manifold from Mold Hotrunner Solutions (MHS), Georgetown, Ont. It has hinged melt-transfer joints that allow linked manifolds to move freely in order to distribute plastic anywhere inside the mold—even directly inside moving slides and lifters. The technology enables a continuous melt path across moving mold elements that are necessary for demolding complex parts with exterior undercut side features like ribbing. This type of flexible manifold can be useful for stack molds, tandem molds, and rotary and cube molds, MHS says.

Lightweighting is a major driver in automotive plastics applications, and a collaboration between 3M and Trexel has resulted in a new way to accomplish larger weight savings while retaining acceptable mechanical properties. This development teams up the newest hollow glass microsphere from 3M, St. Paul, Minn., with the MuCell microcellular foaming process from Trexel, Wilmington, Mass. Trials with glass-filled nylon and PP auto parts using MuCell direct gas injection and 8-10% by weight of 3M’s iM16K Glass Bubbles (introduced this past February) produced 15-20% density reduction—more than could be achieved with either means alone—while retaining comparable mechanical properties and equal or slightly (5-10%) lower cost. Improved properties might be obtained with surface-treated microspheres, which were not tested.

Side benefits are said to include improved dimensional stability and faster cycles from better flow and reduced stresses. Cross-sections of the parts show that the foam cells and microspheres are about the same size. There are no microspheres in the surface skin, which is slightly smoother than a standard MuCell part, though not Class A.

EXTRUSION NEWS

In blown film extrusion, one of the highlights of K 2013 was the introduction by Windmoeller & Hoelscher (U.S. office in Lincoln, R. I.) of the Varex II line. Three years in the making, the new system was tucked into a corner of W&H’s booth and accessible by invitation only. Even then, visitors had to be escorted through a curtain and around a cordoned corridor to see the system in action.

The line featured a sleek, completely enclosed design that several onlookers thought looked more like an Apple product than typical industrial equipment. There were no cables to possibly trip over or duct work or electrical wiring in sight. The extruders and die/air-ring package were cladded—but accessible for maintenance—in what looked like fine cabinetry. A lightweight air ring made of polycarbonate was insulated to mitigate the effects of condensation.

Throughout the show, W&H made five-layer shrink collation film at 40-micron thickness. Running with a 16-in. Maxicone P die, material was processed at 2200 lb/hr, or 44 lb/hr/in. of die circumference. The trimless system ran at a layflat width of 83 in. W&H has sold seven such systems in the U.S., two of which are seven-layer.

Varex II is available with working widths up to 142 in. and can be specified for up to 11 layers. At the show, W&H ran two 60- and 70-mm (about 2.5- and 3-in.) extruders along with a 105-mm (4-in.) machine. The size range also includes 50- and 120-mm (roughly 2- and 5-in.) extruders. Die diameters range from 120 to 900 mm (5 to 35 in.).

Extruders feature what W&H calls “flow-optimized” barrier screws to provide maximum flexibility for processing a wide range of materials. A patented melt-distribution system allows for compact design of the Maxicone P die while keeping pressure losses low. The die was equipped W&H’s Optifil P auto-gauge profile control system, which enables targeted control of the melt temperature on the bubble circumference to reduce gauge variations.

The line also featured the Arctis high-performance, dual-lip air-ring system, an upgrade of W&H’s Opticool air ring that is said to boost output by 5-10%. The air ring’s position relative to the die can be adjusted to optimize blow-up ratio. A new bubble collapsing unit in the film hauloff features automatic adjustment of the lateral guide elements, which reportedly improves film flatness while minimizing film curvature. Featuring a comprehensive range of optional specifications, the new Filmatic S II winder can be tailored to any application.

The new system also is equipped with a 24-in. touchscreen interface that includes control modules aimed at helping film processors reduce waste and improve efficiency and sustainability. These include Easy-Change, an “autopilot” for size changeovers; Easy-Wind, a winder control concept for optimum roll quality; Profile-Booster, designed to accelerate line startup; and Purge Assist, for automatic purging of the extruders and dies.

Other automation modules include Energy Monitoring, which displays the energy usage of individual system components, identifying possible energy savings in the course of production.

A web-based Production Planning and Control module permits decentralized job preparation and control. Order specifications and product formulations can be transmitted directly from a plant ERP system to the extrusion line, without the operator having to enter any order data locally on the machine.

BLOW MOLDING AT K

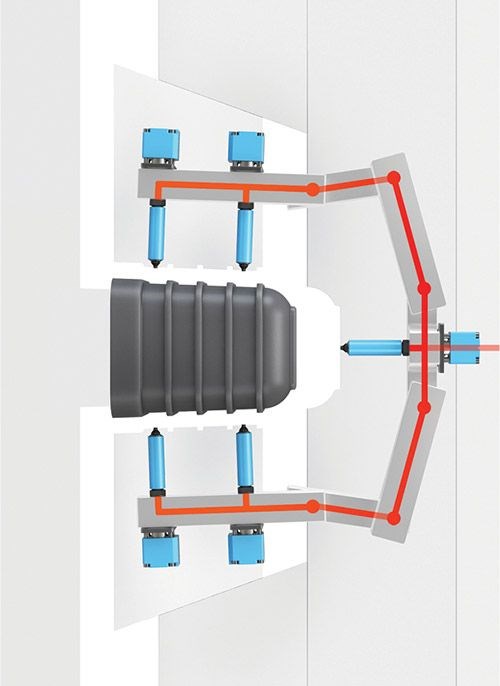

Foam blow molding re-emerged as a theme at this year’s K show. Trexel, Inc., Wilmington, Mass., showed off a developmental HDPE automotive air duct blow molded on an accumulator-head machine using Trexel’s MuCell process with direct gas injection into the machine barrel. The duct has 1.5-2 mm wall thickness and a 41% density reduction, resulting in a 32% net weight saving vs. a solid part. Trexel believes that optimized part design and material formulation could result in more than 40% weight reduction. Foam was found to yield additional benefits, such as improved thermal and acoustical insulation.

Meanwhile, MuCell Extrusion LLC, Woburn, Mass., a company unconnected to Trexel that

markets the MuCell process only for extrusion and blow molding, already has one Japanese customer, Kyoraku Co., Ltd., Tokyo, that has blow molded microcellular HDPE auto ducts for several years. It claims 50% weight reduction and 3.5 db noise reduction vs. conventional solid ducts with PUR foam sound insulation. Kyoraku offers to help other companies implement MuCell blow molding.

MuCell Extrusion also reports that several makers of personal-care packaging are interested in blowing foamed bottles for material savings and improved sustainability.

Other blow molding news includes the ability to produce PET bottles for milk and other light-sensitive products with 100% light-blocking ability to protect nutrients from UV degradation. The bottles are made with multi-layer preform coinjection technology from Kortec, Inc., Rowley, Mass., in cooperation with Sidel Inc., Norcross, Ga. New Kortec LB technology molds three-layer preforms with white PET on the outside, black PET in the middle, and white PET on the inside. This approach reportedly ensures that the black light-blocking layer covers the whole of the bottle, including the base, allowing no light entry. A three-position valve pin in the Kortec nozzle closes off the black layer before the end of injection so that it is completely encapsulated. Over a year of work was needed to optimize the amount of colorant used for maximum cost-effectiveness. Some carbon black is saved by not filling the black layer into all of the neck area, since some is covered by the cap.

Kortec LB technology is available for up to 128 cavities. A 1-liter preform currently weighs 25 g, though 22 g preforms are in development.

NEW DECORATING TECHNOLOGIES

The Kurz Group (U.S. office in Charlotte, N.C.) unveiled two new decorating technologies. First, its patented 3DHS finishing process is a method of decorating 3D geometries. The system consists of the 3DHS hot-stamping foil, tooling system, and hot-stamp machine. Kurz offers the 3DHS foil in chrome, brushed metal, or colors. The highly elastic foil can be heat formed prior to hot stamping to match 3D part geometry.

The tooling system comprises fixing elements for securing the foil to be shaped and a hot-stamp die developed by Hinderer + Muhlich, a member of the Kurz Group. Another subsidiary, Baier, developed the 3DHS hot-stamp machine. At the show, Kurz partially coated an auto air-vent panel with chrome. The part’s 3D geometry cannot be hot stamped conventionally. It would typically require two molded parts—an undecorated base and a chrome-plated ring.

The second new process was developed by Kurz and its German subsidiary, PolyIC, to combine in-mold labeling (IML) and in-mold decoration (IMD) in a single injection molding process for touchscreen and touch-sensitive buttons used in communication devices, vehicles, and appliances. In addition to special mold technology, it is primarily the IML-capable PolyTC sensor films—clear, flexible PET films with electrically conductive coatings—that enable new possibilities in RFID tags, displays, and solar cells.

The conductive material typically used for such coatings is indium-tin-oxide (ITO), which suffers from high preparation costs, low conductivity for large surface areas, and brittleness. PolyIC uses very fine (down to 10 microns) silver mesh to make the film conductive with only a very small portion of its area covered by the mesh. PolyIC’s sensor films are flexible and can

be incorporated in curved surfaces.

In the three-step molding process, the IML PolyTC label is first laid in the stationary injection mold half. The IMD foil with decorative coating is positioned by roll-to-roll feeding in the other mold half. Plastic is injected between the label and IMD foil to create a finished component. This process was demonstrated at the show by Sumitomo (SHI) Demag (U.S. office in Strongsville, Ohio).

MATERIALS NEWS

A compatibilization technology that appears to be a breakthrough in combining polar and nonpolar resins with PP was unveiled by Dow Chemical’s Elastomers group, Midland, Mich. The key ingredient is Dow’s second-generation olefin block copolymers (OBCs). Called Intune, the PP-based OBC’s can compatibilize PP with PE, polyolefin elastomers (POEs), and polar materials like EVOH and nylon. When launched commercially next year,

the Intune OBCs will make possible PP blends and multilayer structures that offer enhanced performance at lower system cost across a broad range of end-uses, including packaging, consumer durables, transportation, construction, hygiene, and wire/cable.

New patented polymer technology from Solvay Engineered Polymers (U.S. office in Auburn Hills, Mich.) reportedly fills the gap between nylon 6 and polyphthalamide (PPA). Based on nylon chemistry, Technyl One is designed to address miniaturization challenges of fire-resistant electrical and electronic devices. Pilot applications include high-range mini circuit breakers, molded-case circuit breakers and contactors.

Halogen-free flame-retardant Technyl One allows a wide processing window—20% broader than for nylon 6 or 66—and good surface finish, even with 50% glass reinforcement. There is no risk of corrosion of tools and injection machines, unlike with PPA. The material has a UL 94V-0 rating at only 0.4 mm thickness, low smoke generation, and unmatched thermal aging properties—150 C Relative Thermal Index, vs. 130 C for nylons 6 and 66 and 140 C for PPA. Electrical properties include a CTI of 600 V and higher.

In polyolefins, Borealis (U.S.office in Port Murray, N.J.) unveiled a new LDPE homopolymer produced with high-pressure tubular technology. CT7200 LDPE is said to ensure long-term supply of LDPE for extrusion coating when several old autoclave polymerization plants will be closing in coming years. Borealis’ new plant is said to produce grades that match the performance and quality of autoclave LDPE.

CT7200 is said to share the high-quality organoleptics of current materials yet also has advantages, such as high zero-shear viscosity that contributes to improved sealing performance. Improved flow enhances adhesion to various substrates, even at low temperatures. And processors can benefit from reduced energy consumption (motor load) at the same output rates, thanks to high shear-thinning behavior.

Related Content

Semperit Acquires Rico Group

The global maker of specialized polymer products for industrial applications, including hoses and belts, has purchased the Austrian headquartered liquid silicone rubber molder and moldmaker.

Read MorePartnership Augments LSR Molding Simulation

SIGMA Engineering and Momentive Performance Materials announced a cooperation to optimize material data for silicone elastomers to make LSR molding simulation more reliable.

Read MoreLSR Molder Invests in Canadian Operation

Starlim is investing $10.4 million in its London, Ontario, LSR injection molding site, with plans to add 26 jobs.

Read MoreMilacron’s Massive Booth Highlights Multiple Brands

NPE2024: Coinjection of postconsumer resin, in-mold decoration, LSR micromolding and bioplastics processing are just some of the machine displays at Milacron's booth.

Read MoreRead Next

K 2013 Preview: Materials & Additives

The K 2013 show will present a broad range of engineered plastics materials, including thermoplastic composites, as well as additives. Automotive and electronic applications will be the main targets, as well as medical, packaging, lighting, and construction.

Read MoreK 2013 Preview: Extrusion, Compounding, Recycling

Across all extrusion technologies, expect to see new standards in speed, quality, flexibility, and efficiency in both energy and material usage.

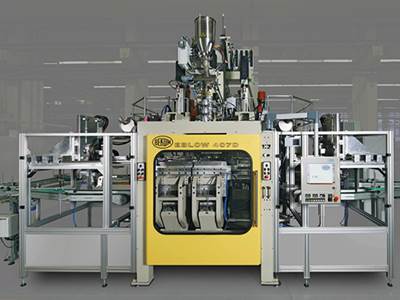

Read MoreK 2013 Preview: Blow Molding

Of the six machine builders who were willing to pull back the curtain even a little, five of them said they’d be showcasing all-electric presses. That remarkable fact suggests that all-electric technology, which has been a much harder sell in blow molding than in injection molding, is at last starting to find traction.

Read More