Hot Runner Nozzle’s Cable Location Shifted

Hasco has extended its Vario Shot nozzle range and optimized its cable location.

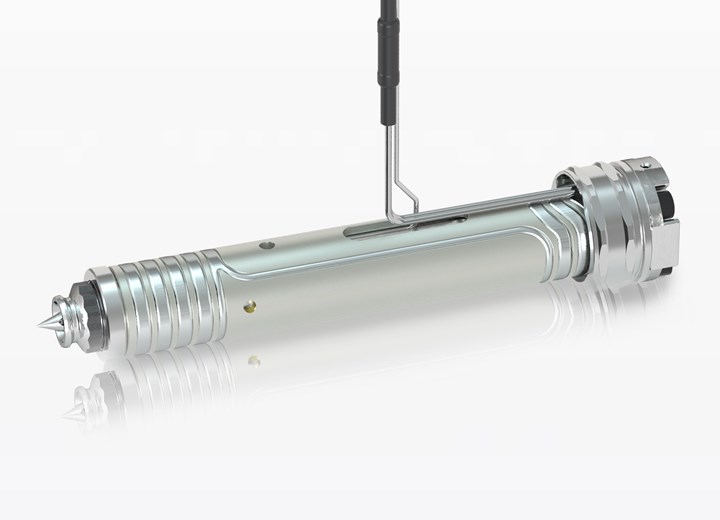

Hasco has expanded its line Vario Shot hot runner nozzles and developed a version where the cable outlet has been moved to the middle of the nozzle, relocating it outside the hot half in the nozzle retainer plate.

From a maintenance standpoint, this optimized cable location allows the heater to be easily replaced while the mold is in the press. In the case of multi-cavity hot runner molds or needle valve applications, processors will no longer need to dismantle the hot runner and remove the needle during service. Hasco notes that the hot runner nozzle’s thermocouple can be replaced from the parting plane. Through a strategically placed groove in the heater’s brass body, the thermocouple can be easily dismantled and mounted again.

Hasco has shifted the cable location for its Vario Shot hot runner nozzles, easing maintenance.

Related Content

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.