How Pre-Loaded Ultrasonic Welders Save Time in Automated Assembly

Pre-loaded assembly systems mounted on a robot arm are a relatively new, time-saving concept in ultrasonic welding that maintains precision and process repeatability.

Although pre-loaded assembly systems are well known in automation, they are a relatively new concept in ultrasonic welding. Ultrasonic pre-loading means that the cylinder already has been extended via an intelligent pneumatic system when the weld tool comes in contact with the plastic parts, so that the welding process can start immediately. This saves time without compromising on precision or process repeatability.

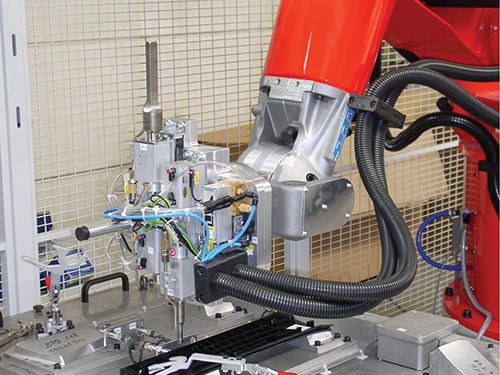

Lightweight and compact ultrasonic weld actuators, along with process controls such as Herrmann Ultrasonics’ Vario, offer this feature. Mounted easily on robot arms, these actuators increase output by facilitating fast and low-energy welding of plastic components.

The high processing speed offered by ultrasonic welding makes it very attractive for mass production, despite higher initial investment. During the weld, the ultrasonic vibrations generated from electrical voltage precisely melt the plastic at defined joining points and create a homogeneous bond. Cycle times of less than 1 sec can be realized, depending on the required weld times (between 120 and 500 millisec).

The cold weld tools do not require a heat-up phase and are ready for operation at any time without the need to maintain a certain temperature level. Preliminary application consulting can be crucial, particularly for part design, to ensure that the ultrasonic waves are ideally focused in the joining area.

REDUCED WELD TIMES

Robots are utilized in situations where several identical weld spots must be performed on one large plastic component. Robot cells provide high flexibility for low batch sizes and multiple part configurations. However, the robot performs the welds one by one, which takes time.

With the help of the pre-loaded concept, the up-and-down travel times of the sonotrode (welding horn) can be eliminated and productivity of the robot is increased. This could save as much as 1 sec per weld spot. Time savings can be significant with welding applications such as an auto engine cover or acoustic foam with up to 20 weld spots. Time savings per application in this instance can approach 20 sec.

INTEGRATED SYSTEMS

For applications with very large quantities and repeated production of the same or similar parts, fast automated rotary systems or linear-transfer machines are frequently used. These machines operate in time-optimized cycles; they are partly cam-controlled and partly servo-controlled, with cycle times of 1 sec or less.

Ultrasonic welding systems also can be integrated within automation lines. For example, Herrmann Ultrasonics has developed the VE Slimline product range of welders specifically for automated systems, available in frequencies of 20, 30, and 35 kHz and outputs of up to 6200 W. The 35-kHz VE Compactline, which is even smaller, is mostly used for robot applications. In conjunction with the Vario process control, all are characterized by easy integration into the overall control assembly-cell architecture.

Related Content

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More