How to Dry PET for Container Applications

PET is extremely hygroscopic, highly moisture sensitive, and one of the toughest challenges to dry. Here are the basic principles of doing it right for rigid packaging applications

Polyethylene terephthalate, commonly known as PET, is a popular material for bottles and containers. PET may exist as a clear amorphous material or in semi-crystalline state that is often, though not always, opaque milky white. The IV or (intrinsic viscosity) of the PET resin is probably its most important characteristic. The IV is an indication of the average length of the PET’s polymer chains. The higher the IV, the longer the polymer chains and the higher the performance characteristics it will possess.

IV retention of the PET during processing is critical; anything that may degrade or lower the IV during processing must be monitored and controlled, and the most common cause of IV degradation is the presence of water in the PET. PET is extremely sensitive to absorbed water, which will cause hydrolytic degradation at elevated melt temperatures. Thus, the most important issue is proper drying prior to melt processing.

This article will describe the basic fundamentals of predrying virgin PET pellets for rigid container applications.

THE BASICS OF DRYING PET

PET is hygroscopic: When exposed to the atmosphere it will readily absorb water vapor from the surrounding air. The migration of water vapor into the PET granules occurs over time and will eventually slow and stop when the moisture content reaches a state of equilibrium with that of the surrounding air. At that equilibrium point, the water vapor within the PET granule will be evenly distributed throughout the pellet’s interior.

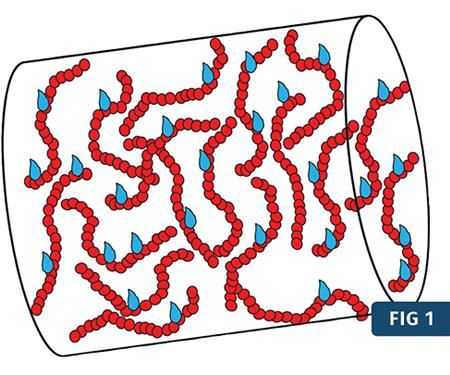

The water molecules are attracted to the polymer chains, forming a strong intermolecular bond (Fig. 1). That bond is what makes drying PET difficult. Even a small amount of moisture in PET will cause a chemical reaction (hydrolysis) when the polymer is heated above its melt temperature.

The drying process involves four fundamental parameters:

• Drying temperature,

• Dewpoint,

• Drying time,

• Airflow.

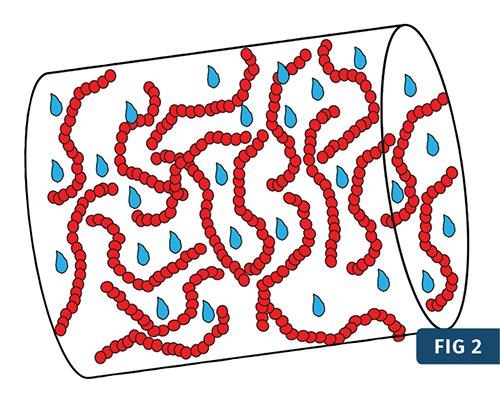

Drying Temperature: Temperature is probably the important consideration in drying any hygroscopic polymer. When the temperature of the PET is increased, its molecules will begin to move about more vigorously, reducing the attraction the water molecules have for the polymer chains, and allowing the water molecules to escape the bonds, as illustrated in Fig. 2.

The polymer temperature therefore has a very strong influence on the diffusion rate of the water molecules through the polymer. The water molecules can travel more freely through the polymer at higher temperatures, when the polymer’s attraction for the water molecules has been reduced.

Heating the PET pellets to the optimum recommended drying temperature is a prerequisite to good drying. Generally speaking, the higher the drying temperature, the more quickly and thoroughly the PET will dry. There are, however, practical limitations to the range of drying temperatures acceptable for PET.

If the drying temperature is too high, thermal degradation and/or oxidation may occur. If the drying temperature is low, the PET will give up its moisture more slowly. Following the recommendations of your material supplier is the best and safest advice to follow.

Dewpoint Temperature: The dewpoint temperature is the second fundamental drying parameter. This term describes the moisture content of the drying air. The dewpoint temperature is the “saturated air temperature” at which condensation will occur.

For example, If you were to gradually reduce the air temperature of the room in which you are sitting, you would eventually reach a temperature at which condensation would occur. That is the saturated air temperature, or dewpoint.

If you were to repeat that experiment with a sample of air from a dryer that has been dehumidified to -40 F dewpoint, you would need to reduce the air’s temperature to -40 F before condensation would begin to occur.

Another more common example: When you leave the house on an early summer morning and see “dew” on the grass it is because the temperature of the air fell below the saturated air temperature or dewpoint during the night and condensation occurred.

How does the low-dewpoint air from a dryer remove the moisture from the PET granules in the drying hopper? First, the drying air is dehumidified to a very low residual moisture content by filtering the air through a moisture-adsorbing desiccant material. Then, the drying air is heated to the desired drying temperature. Heating the dehumidified air reduces its relative humidity to an extremely low level and further increases the drying air’s moisture-absorption capacity.

When PET pellets are surrounded with low-dewpoint air, which has been heated to 300 F or higher, the vapor-pressure differential between the surface of the pellets and the drying air is greatly increased.

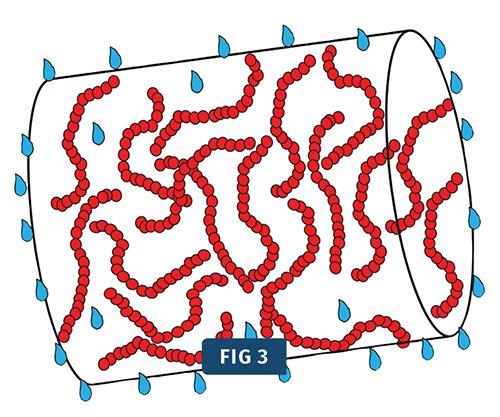

Once the polymer has been heated and the attraction between the water molecules and the polymer chains has been sufficiently reduced, the freed water molecules will begin to migrate toward the area of low vapor pressure at the surface of the pellets, as illustrated in Fig. 3. When the water molecules reach the surface of the pellets they will be quickly swept away by the drying air.

Drying Time: PET pellets do not dry instantaneously; the drying time, which is the third fundamental drying parameter, is critical to the drying process. When the PET pellets in the drying hopper have been surrounded with a steady stream of heated, low-dewpoint air, sufficient time must be provided to allow the heat from the surrounding air to migrate to the interior of the pellets.

PET pellets, or any type of plastics pellets, do not conduct heat very well. It therefore takes time for the heat from the surrounding air to be absorbed and distributed throughout the pellet’s interior.

It is important to note that the time the PET pellets spend in the drying hopper is not necessarily effective drying time. The effective drying time is the amount of time the pellets are exposed to air at the correct drying temperature and dewpoint while in the drying hopper.

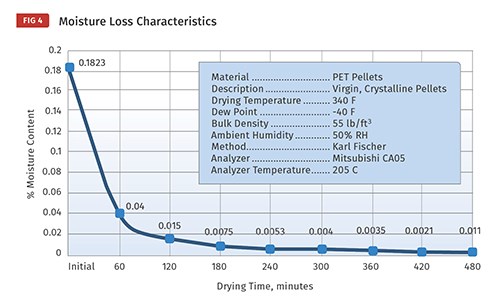

Figure 4 is a moisture-loss analysis of a PET drying system. Small samples of the PET being dried were taken from the hopper every hour during static drying and the residual moisture was analyzed. The drying parameters are described on the chart attached to the graph. Note the dramatic drop in residual moisture during the first hour of drying, from 0.1823% to 0.04%, after which the rate of decline slows significantly, requiring another 4 hr to drop below the desired moisture level of 0.005%

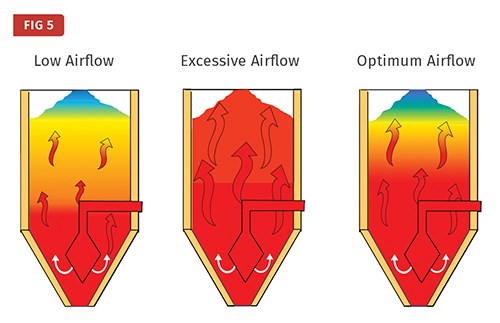

Airflow: Measured in cubic feet per minute (CFM), the airflow of a dehumidifying dryer is the fourth fundamental drying parameter. It is absolutely crucial to the drying process. The airflow of a dehumidifying dryer is the medium that transfers the heated, low-dewpoint drying air from the dryer to the PET pellets in the drying hopper. Insufficient airflow will not transfer enough heat from the dryer’s heat source to the PET pellets in the drying hopper. With insufficient airflow through the drying hopper, the system will not be able to maintain the desired vertical temperature profile within the hopper to provide the required drying time.

Excess airflow will transfer an excessive amount of heat from the dryer’s heaters to the bed of material in the drying hopper. The excess heat that is not absorbed by the PET pellets will exit the drying hopper, resulting in high return-air temperatures, poor desiccant performance, wasted heat energy, high dryer operating costs, and the possibility of overheating and damaging the dryer’s process-air blower.

The volume of airflow needed to adequately dry PET will vary from one drying system to the next, depending upon several factors, including the incoming pellet temperature, drying hopper design, heat losses within the drying system, and hourly throughput (lb/hr) through the hopper. Determining optimum airflow is therefore a complex question that will require a separate article of its own.

But a simple answer to the question of airflow volume is this: You will need enough airflow through the drying hopper to maintain the PET granules at the desired drying temperature for the desired amount of drying time.

Figure 5 is a visual representation of low airflow, excessive airflow, and optimum airflow within a drying hopper. The drying hopper with low airflow will not provide enough drying time at the desired drying temperature. The drying hopper with excessive airflow is heating all of the material within the hopper to the setpoint drying temperature and wasting energy by passing excessive heat back to the dryer. The drying hopper with optimum airflow is developing a vertical temperature profile that is providing the desired amount of drying time and using the fresh, cool incoming material as a heat sink to cool the return air leaving the drying hopper.

OPERATING A DEHUMIDIFYING DRYER

There are three air circuits in a well-designed dehumidifying dryer:

• Closed-loop drying-air circuit;

• Single-pass regeneration-air circuit;

• Desiccant cooling circuit.

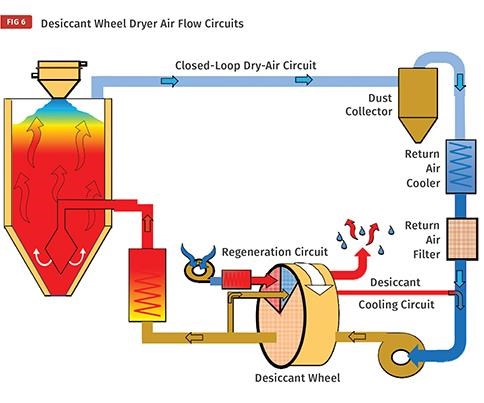

Closed-Loop Dry-Air Circuit: The drying air entering the drying hopper has been dehumidified to a low dewpoint and heated to the selected drying temperature prior to entering the drying hopper (see Fig. 6).

The hot, dry air enters the drying hopper and is dispersed throughout, enveloping each and every PET pellet within the hopper. As the hot, dry air travels upward through the hopper, the drying air gives up its heat to the PET pellets.

As the wet incoming PET pellets begin to absorb the heat from the drying air, they will begin to give up their moisture to the hot, low-dewpoint drying air.

When the drying air exits the top of the hopper, it has given up a substantial amount of its heat to the PET pellets, and in exchange the drying air has absorbed the moisture given up by the resin.

Nearly all of the dehumidifying polymer dryers used in the plastics industry use a closed-loop drying-air circuit. The reason for this is that the moisture content of the air exiting the top of the drying hopper will always be drier than the ambient air. The dewpoint levels in the return-air circuit of a typical PET drying system are usually in the range of zero to -20 F, while ambient dewpoint levels usually run much higher.

Therefore it makes economic sense to employ a closed-loop drying-air circuit to salvage and reuse the moderately dry return air exiting the drying hopper rather than using much wetter ambient air in a single-pass drying-air circuit.

Dust Collector (FIG. 6): The Dust Collector is critical to long-term performance of the heat exchanger. Incoming containers of virgin PET pellets will commonly contain fines, and reground scrap PET often contains large quantities of fines. If these fines are allowed to enter the return-air heat exchanger, many of the fines will adhere to the cooling coils of the heat exchanger. Over a period of time the fines will build up and insulate the cooling coils from the air passing through the heat exchanger, reducing the device’s efficiency. Therefore, it is a good decision to include a dust collector in the system to keep the cooling coils clean and free of fines.

Return air heat exchanger (Fig. 6): Typical PET drying temperatures range from 300 to 350 F. When the drying air exits the top of the drying hopper, it has already given up a substantial amount of its heat content to the PET pellets. The air temperature exiting the top of a typical PET drying hopper will normally be in the range of 200 to 250 F. Even at that reduced temperature, the air is still too hot to return it directly to the dehumidifying dryer.

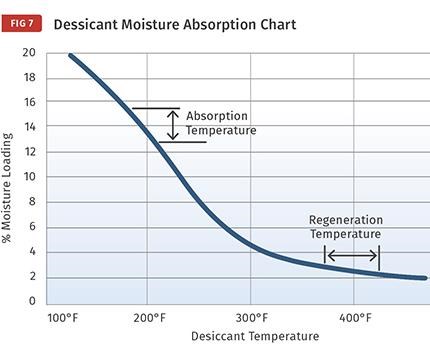

Dehumidifying dryers are sensitive to high return-air temperatures. The reason is the desiccant’s moisture-adsorbing performance is greatly compromised when operating at high temperatures, and it is enhanced when operating at relatively low temperatures (Fig. 7).

The optimum return-air temperature is in the 100 F to 130 F range, where the dryer’s desiccant is capable of adsorbing approximately 15% of its own weight in water.

Return-air filter (Fig. 6): A dehumidifying dryer’s desiccant is sensitive to contamination. The purpose of the return-air filter is to protect the dryer’s desiccant. If PET fines are allowed to bypass the dryer’s return-air filters and enter dryer’s desiccant, the fines will build up and restrict air flow through the desiccant. Depending on the regeneration temperature, the fines may begin to melt or release volatiles and permanently damage the desiccant. Therefore it is critical that any fines present in the return air be filtered out before the air reaches the desiccant.

The dryer’s return-air filter is the second filter in a PET dryer’s return-air circuit, the first being the dust collector. As a general statement, the return-air filters are the most service-intensive components of a PET dryer. Depending on the amount of fines in the material being dried, the return-air filter may require cleaning or replacement as frequently as every shift or as little as every several months.

Maintaining the dryer’s unrestricted airflow is critical to its performance. The only prudent way to determine a reasonable schedule for filter maintenance is to monitor the condition of the return-air filter on a daily basis over a period of time. Then develop a filter maintenance schedule that fits your application.

Air Blower (fig. 6): The air blower moves the drying air through the drying-air circuit. The dryer’s blower must move a large enough volume of air through the drying-air circuit to overcome the heat losses in the dryer, air-delivery tubing, and the sidewalls of the drying hopper.

The dryer’s blower must also move a large enough volume of air to heat the incoming PET material from its initial temperature (usually ambient) to the desired drying temperature of 300 F to 350 F. The blower must also be able develop enough pressure to force the requisite volume of airflow through the drying hopper, which could be as high as 20 to 30 in. of water column when a heavy loading of regrind and fines is being dried.

Desiccant (fig. 6): The desiccant is the heart of the dehumidifying dryer. It is the substance that removes the moisture from the drying air that is returning from the drying hopper. This moisture needs to be removed from the return air in order to reduce the air’s dewpoint back into the range of -30 F to -40 F.

The most common type of desiccant used in dehumidifying-air polymer dryers is molecular-sieve desiccant made from a synthetic zeolite material. The molecular sieve will filter out molecules from the drying air that are smaller than the desiccant’s pores.

Manufacturers of PET bottles used for soft drinks and water are concerned with the acetaldehyde (AA) levels in the PET preforms they are producing because AA will change the flavor of the bottled drink. Virgin PET normally has AA levels in the range of 1 to 3 ppm, while reground PET may have an AA level of 10 to 15 ppm or more. Dryers used for PET bottle production usually employ a 13X desiccant, which adsorbs both AA and water molecules from the dryer’s return-air circuit.

Air heaters (Fig. 6): Typical PET drying temperatures are in the range of 300 F to 350 F. Either electrical or natural-gas heaters can be employed in a PET dryer. Electrical heaters are less complex and less costly than gas heaters, but their downside is the skyrocketing cost of electricity. Depending on your location, the cost of electricity can be several times more than natural gas.

If you are considering the purchase of a gas-heated dryer for PET, be careful to specify indirect heat exchangers in the both the drying-air and regeneration-air circuit heaters. An indirect heat exchanger in the drying-air circuit separates the combustion air from the drying air, which will guarantee no combustion exhaust gases will come into contact with and contaminate the PET being dried.

An indirect heat exchanger in the regeneration-air circuit is also important. It separates the combustion air from the regeneration air, which will guarantee that no combustion exhaust gases will come into contact with your dryer’s desiccant.

Regeneration Air Circuit (Fig. 6): The regeneration-air circuit of a PET dryer utilizes ambient plant air in a single-pass circuit to purge the adsorbed moisture from the desiccant out to the atmosphere.

Inlet Air Filter: Regeneration air is drawn in from the atmosphere and first filtered of any possible contaminants prior to contacting the desiccant.

Regeneration air blower: The regeneration blower moves the air through the single-pass regeneration-air circuit. A sufficient volume of airflow is required to elevate the desiccant’s temperature in order to heat the desiccant and purge its adsorbed moisture.

Regeneration air heaters: Heating the desiccant to a high temperature is necessary for regeneration. These heaters must have enough heating capacity to raise the temperature of the regeneration air to the factory-set regeneration temperature in order achieve complete desiccant regeneration.

Regeneration Moisture Exhaust: As the temperature of the desiccant is increased it will begin releasing its adsorbed moisture. The released moisture will be purged to the atmosphere through the moisture exhaust port.

Desiccant Cooling circuit: The desiccant’s temperature on completion of the regeneration cycle is elevated and its residual moisture content is at a very low level. The desiccant must be cooled prior to being moved into the process-air stream (Fig. 7).

If hot desiccant is moved into the on-stream position it will not adsorb moisture from the air returning from the drying hopper. The moisture present in the air returning from the hopper will pass right through the hot desiccant, resulting in high-dewpoint air being recirculated into the drying hopper.

Typically, a small. controlled volume of air from the drying-air circuit is bled through the desiccant in the cooling position. Some older designs of dryers use ambient air to cool the desiccant after regeneration, which results in preloading the desiccant with some ambient moisture as the desiccant’s temperature is reduced during cooling.

The benefit of cooling the hot, freshly regenerated desiccant with a slipstream from the drying-air circuit is that the desiccant is being cooled with the moderately dry air from the dryer’s return-air circuit, rather than ambient plant air, which may have a very high moisture content, depending on local weather conditions.

Related Content

Finding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read More'Smart,' Moisture-Based Drying Technology Enhanced

At NPE2024, Novatec relaunches DryerGenie with a goal to putting an end to drying based on time.

Read MoreNovatec Putting the ‘Smart’ In Resin Drying, Conveying

NPE2024: Machine builder gets ‘ludicrous’ by rewriting the rules for material drying and conveying.

Read MoreSoftware Helps Processors Make Better Business Decisions

NPE2024: Tracker Monitoring and Reporting Software supports ISO reporting and material validation, including PCR usage and equipment status monitoring.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More