From K 1998: Injection Molding Highlights

K'98 showed off a wide range of technologies that cut costs by consolidating process steps.

K'98 showed off a wide range of technologies that cut costs by consolidating process steps. One of the most unusual was in-line compounding and molding of filled PP with a Berstorff twin-screw extruder mounted piggyback on a Krauss-Maffei press (see PT, Dec. '98, p. 13). Other examples were paint replacement by molded-in films, minimizing assembly through two-component molding, in-mold labeling that eliminates secondary steps, and a new way to make auto intake manifolds without welding or lost cores.

The show also featured its share of new machinery in both hydraulic and all-electric configurations. Besides a multitude of general-purpose machines, specialized equipment of all stripes appeared too, including models for PET preforms, CDs, and micro parts.

No-paint decorating

Several new and updated methods for insert molding with decorative or functional films appeared at the show. Among these was a method for producing paintless exterior car-body components. As reported last month (p. 13), "Paintless Film Molding," or PFM, involves injection-compression molding a backing substrate onto a thermoformed weatherable film with colored and clear-coat layers. A complex automation system that employs an articulated-arm robot automatically places the film in the tool. PFM is a joint development of BASF, Engel, and two German suppliers of film and coatings.

Another in-mold film technique was demonstrated by Battenfeld on a machine with three injection units, two of them tiny vertical units mounted on either side of the stationary platen. Bumpers were produced with a printed and thermoformed polycarbonate film from Bayer that was back-molded with PBT. The two auxiliary injectors added a TPU seal strip on one side and a clear PC lens for the turning lights on the other.

For lids and other shallow-draw parts, Tradesco created a simple in-mold labeling (IML) system. It takes printed labels from a magazine and transfers them into the tool for overmolding. The mold-mounted label-transfer arm is driven by the opening and closing of the clamp and a spline/bearing assembly. No extra controls are needed for this mechanical system. Labels are stored in quick-change cartridges.

Dr. Boy GmbH also showed an in-mold labeling system: It had a servo robot to feed printed films into the mold on a 33-ton Boy press.

Mold once, mold twice

Multi-component molding appeared in the booth of every major machinery manufacturer--including Ferromatik Milacron, Battenfeld, Demag, Engel, and Netstal (see September show preview, p. 58). Systems that co-mold liquid silicone rubber and a thermoplastic were demonstrated by Battenfeld and Demag (represented here by Van Dorn Demag). New small machines for multi-component molding were shown by Arburg (55 tons) and Boy (30 tons).

Another two-component technology came from Ewikon, which showed its "coaxial-needle" hot-runner valve gates. Consisting of a center needle surrounded by a second hollow needle, this device injects both melts at the same point (see schematic). During injection, the hollow needle opens first to allow injection of the first component. Once it closes, the center needle opens for the second component and then shuts off to seal the gate. With different sequencing, the system can also be used for parts in which one layer encapsulates another--including parts with foamed cores.

Strong electric showing

K'98 provided evidence that all-electric machines are on the upswing. Milacron introduced a new high-speed electric model, and Battenfeld announced its all-electric MicroSystem for tiny parts. Other debuts included the following:

Toshiba introduced its first line of all-electrics ranging from 40 to 275 tons. The 40-tonner will be the first one available here. These presses borrow high-performance AC servo-motor and control technology from Toshiba's machine-tool business.

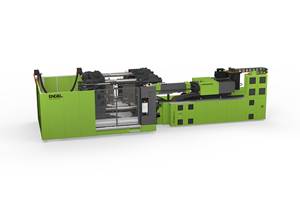

Engel extended the electric machine concept with a tiebarless model. This 110-ton machine employs five servo motors to handle the various machine movements simultaneously. Dry-cycle time is reported to be 8.5 sec. Automatic closed-loop control of clamp force is achieved by adjusting nuts behind the platen.

Ube has built a 935-ton all-electric model, the world's largest, in concert with Niigata. To power such a large press, AC servo motors are paired in a twin synchronous drive. Early this year, Ube will add a 730-ton model, and a 1430-tonner is in the works.

Nissei showed four kinds of electric molding machines: a 7.7-ton model on casters, a CD machine, a 170-ton representative of its Elject ES line, and a 44-ton Elject model with the company's Triplemelt precision injection technology.

Meanwhile, Demag showed off its new hybrid technology using decentralized hydraulic and electric drives. Called "Elexis," this new machine has separate hydraulic piston pumps on the clamp and injector, each pump driven by an AC frequency motor. The screw can have either electric or hydraulic drive (see PT, Dec. '98, p. 11).

PET preforms go vertical

The show also abounded with new PET preform machines, including two vertical-clamp models and a new 96-cavity system.

Krauss-Maffei ran its new 193-ton KM V-24 PETform vertical machine at the show with a new side-entry takeout robot and preform-cooling system from Wittmann. The vertical configuration reportedly helps maintain mold alignment and uniform heat distribution in the hot-runner system. But most of all, it aids ejection. Preforms drop onto the robot's gripper arm without the need for vacuum. After molding, the preforms go into the rotating-drum cooling station, where they remain for three cycles. The PETform system comes with 24 or 48 cavities.

Another new vertical-clamp PET machine was introduced by Arburg. Shown on a 110-ton Jubilee machine with an electric screw drive, the 16-cavity system was said to make about 4 shots per min for a total of more than 90,000 preforms a day. A stripper plate transfers preforms to a cooled take-out platen.

Husky showed a pair of preform machinery developments: The company has a new smaller model of its Index rotating-platen machine. The 99-ton IN 90 takes either two or four sets of mold cores. It's intended for molders with lower production volumes than the 48-cavity IN 250 or 96 cavity IN 400. Also new from Husky is a post-mold cooling system that reportedly shaves 15% off the cooling times achieved by Husky's previous robotic cooling system. Called CoolJet, the system has a water-cooled takeoff plate with a newly optimized coolant flow.

Netstal showed a 96-cavity PET preform system based on a 660-ton SynErgy toggle press. It has an electric screw motor, overhead parts-removal robot mounted on the clamp, and three-position cooling block over the clamp. The total clamp cycle is said to be only 2.7 sec (lock-up to lock-up). It reportedly molds half-liter water-bottle preforms (21 g) in 9.5 sec. A Coke-style contoured half-liter would require a 13-14 sec cycle. Because the machine uses a two-stage injection unit, it can be converted to a multi-layer 48-cavity machine.

Three-platen shorty

Battenfeld has cut about 15% off the length of its HM Series three-platen hydromechanical machines, which range from 660 to 4950 tons. Company spokesmen say the machines are now comparable in footprint to many two-platen machines.

Larger toggles, smaller hydraulics

This year, Demag will extend both ends of its size range. The largest toggle clamps will expand from the current 1650 tons up to 2200 tons. And the smallest hydraulic model will shrink from 27.5 tons down to 16.5 tons.

Bigger shots

Arburg's new 570 C Jubilee machine of 220 tons can be outfitted with a 30-oz shot capacity, up from the company's previous maximum of 15 oz. Another option is electric screw drive.

Fancier controls

Arburg also updated its toggle machines by adding the high-end Selogica controller. They are now called the Allrounder 221 K series, available in 27.5 and 38.5 tons.

Larger tiebarless

Engel rolled out a 660-ton tiebarless model, which molded tv enclosures with gas assist at the show.

New toggles

Sandretto introduced the "Series Nine"--eight toggle machines from 75 to 550 tons with shot capacities of 8.5 to 366 cu in. and injection pressures to 38,500 psi.

Gas-assist press

A molding machine dedicated to the gas-assist process was introduced by Gas Injection Ltd. of the U.K. The machines have low clamp forces and large platen areas and shot sizes. A gas nozzle with an integrated shut-off valve is standard. Gas-control equipment is housed in the machine frame, and gas connections are built into both platens. Current sizes are 22 to 660 tons, and a 1320-tonner is in the works.

Smart cards

Arburg showed a smart-card production line designed to make 800 cards/hr in a single-cavity tool supplied by Axxicon. Called "Smartliner 800," the system features integrated parts handling and laser marking.

Disc systems.

A 55-ton all-electric CD machine was shown by Milacron, while Nissei introduced an all-electric 44-tonner for CDs and DVDs. It was shown with a compact replication system that fits into 1 square meter.

Krauss-Maffei showed a revamped CD injection-compression machine with a shortened injection unit and enlarged barrel diameter. For DVDs, Krauss-Maffei has developed a uv bonder as an alternative to the company's hot-melt bonder. This development will allow the company to introduce a complete DVD-9 line this year.

Micro molding

Boy showed its 12-ton machine with a needle injection unit capable of shot volumes as small as 2 cc. Smaller shots are in development. As further testimony to the interest in micro molding, Battenfeld showed off a 5.5-ton system with three-stage injection, and Milacron added a 0.11-g auxiliary micro injector to a 95-ton press (see PT, Aug. '98, p. 41 and Sept. '98, p. 59).

LIM plus gas

Engel added gas assist to a 55-ton LSR machine in order to make a sprueless medical catheter in a two-cavity cold-runner thermoset mold. Meanwhile, Arburg has added its high-end Selogica controller to its LSR systems. The controller is said to simplify operation by handling set-up of the LSR pump.

Simulation gets a new dimension

Addressing the need to better simulate flow into thick parts like electronic connectors, two companies introduced what are described as the first "true 3-D" flow-simulation packages. Moldflow's new MF/Flow 3D software builds a 3-D mesh out of tetrahedral solid elements (PT, Dec. '98, p. 11). Plastics & Computer introduced FaSolid PC software that relies on hexahedral or brick-shaped solid elements.

Robots lend a hand

Husky's new Moduline top-entry robot has 110-lb payload capacity and a long stripping axis, suiting it to deep-draw parts. It was shown in an in-line configuration, depositing parts at the end of the machine rather than the side. The result is a narrow work cell.

Another new robot was shown by Italy's Sytrama, which recently became part of AEC Sterling Corp. The company's RSV 202 robot uses a new linear motor to drastically reduce the number of moving parts.

Related Content

Energy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

Read MoreNew Designs for Electric & Hybrid Packaging and Industrial Blow Molding Machines

Introduced at K 2022, Bekum’s 21 models in the new EBLOW 8 Series and XBLOW designs include all-electric packaging machines from small to large, plus industrial units with a novel two-stage clamp in servohydraulic or hybrid versions.

Read MoreSingle-Inlet Air Ring

Easy to maintain an operate, it’s integrated in the blown film line through just one cooling air supply line.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More