New Designs for Electric & Hybrid Packaging and Industrial Blow Molding Machines

Introduced at K 2022, Bekum’s 21 models in the new EBLOW 8 Series and XBLOW designs include all-electric packaging machines from small to large, plus industrial units with a novel two-stage clamp in servohydraulic or hybrid versions.

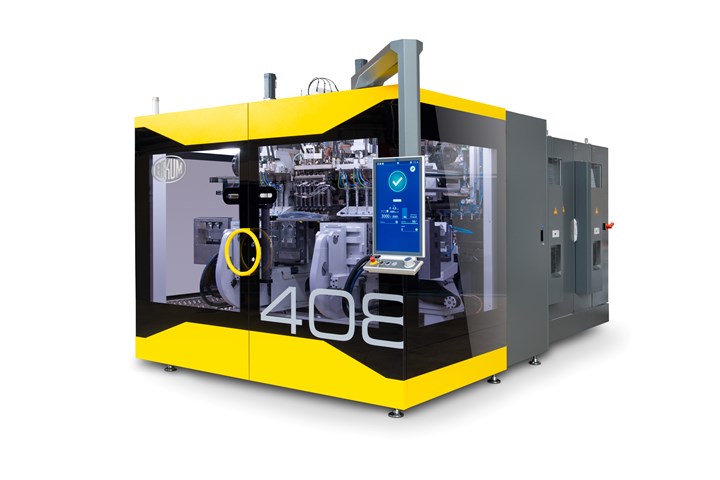

Bekum’s EBLOW 408D, shown at K 2022, is part of the extensive new 8-Series of all-electric shuttle machines with energy-efficient extruders, spiral-mandrel heads and new BC 8.0 controls. (Photos: Bekum)

At the recent K 2022 show in Düsseldorf, Bekum stood out for the largest number of new blow molding models introduced. These included 17 all-electric shuttles for packaging in a wide range of sizes, plus four industrial machines featuring a new, patented hybrid clamp design. All these new extrusion blow molders are composed of standard modules to offer both flexibility and short delivery times. They share Bekum’s new energy-optimized HiPEx 36D extruders, new spiral-mandrel extrusion heads, and new BC 8.0 controls with 24-in. display and a dashboard for visualization of throughput values and energy consumption. The controls are also described as “Industry 4.0-capable,” with features such as remote digital troubleshooting and artificial-intelligence (AI) product-quality monitoring.

More details are now available on these machines, which were previewed briefly in September’s Keeping Up.

All-Electric Packaging Machines

The all-electric shuttles constitute Bekum’s new flagship 8 series with a sleek design that was shown in prototype form at K 2019. These continuous-extrusion machines fall into two groups: small machines for pharmaceutical, cosmetics and consumer packaging; and machines for larger packaging such as canisters especially. The small machines are the EBLOW 208, 308 and 408 in single- and double-sided models with Bekum’s C-frame clamp in 6 to 12 metric tons and integrated top calibration force of 1.5 m.t. Mold carriage strokes are from 280 to 520 mm. Maximum container capacity is 2 × 1 L, 3 × 1 L and 4 × 1 L, respectively.

The machines are designed for quick changeovers, starting with two front door that open for easy access to the head and mold, plus sufficient ground clearance beneath the lower connecting beam of the front gates to allow a forklift’s wheel arms to retract; quick-release levers on the rear clamping platen; and optional double-sided mechanical quick-change system from a well-known supplier.

Energy-saving servodrives feed their braking energy back to the extruder drive, helping these models achieve specific energy consumption less than 0.29 kWh/kg of resin processed, meeting or exceeding the most efficient machinery class 10 under Euromap 46.1, according to Bekum.

Additionally, these small machines are designed for delivery as one complete unit in a standard shipping container — which Bekum calls the “Pack and Go” concept.

The larger packaging machines in the all-electric 8 Series — EBLOW 508, 608, 708, 808, 1008 and 1208. All are available as double-station machines; the EBLOW 508, 608 and 708 are also available with single stations. Clamp capacities are 20 to 50 m.t. and carriage strokes are 520 to 1280 mm. These machines can produce up to 3 × 10 L or 4 × 5 L containers.

All models have C-frame clamps; those from 20 to 50 m.t. use a new electromechanical, double-crank e-Twin-Toggle system. This unique design reportedly produces almost no wear-inducing friction for exceptionally long service life. Automatic mold-thickness adjustment is standard. Dry-cycle times are 1.8 to 3.7 sec. Calibration force is 2 or 4 m.t. Fast-acting, precise application of force during pinch-off can provide perfect pinch-off seams, important for clean trimming, especially with demanding materials like PP, PC and PET, Bekum states. Braking energy of the carriage movement is fed back into the system. Overall energy efficiency reportedly meets Euromap 46.1 class 10, as with the smaller EBLOW machines.

Functions such as the bobbing extruder platform, takeout devices, calibration and punching are all electromechanically driven, though hydraulic drive is optional for calibration, punching and mold actions. Wall-thickness control can be either electromechanical or hydraulic.

Supply and return of cooling water to the mold is from the bottom of the mold in the standard version. Molds are mounted on the platens with mechanical couplings and mold changes reportedly can be completed in less than 15 min per side.

A linear transport system for part removal at the rear of the machine is standard. Models 508, 608 and 708, which are particularly suited to canister production, can be optionally equipped with three-station removal and a bottom calibration station.

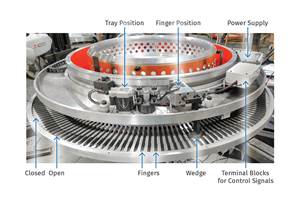

Bekum’s XBLOW hybrid industrial machines (accumulator head or continuous extrusion) are distinguished by their new two-stage servohydraulic or hybrid-electric clamps with two diagonal tiebars and the special ability to be set from the operator panel for a wide range of mold thicknesses (patent pending).

Industrial Models Sport New Clamp Design

Also based on the external design of the EBLOW 8 Series are four new industrial machines in the new XBLOW series — XBLOW 50, 100, 200 and 300 — of 40 to 300 m.t., which can have either accumulator heads or continuous extrusion. They are designed for canisters, IBC, drums, water tanks and technical parts up to 1000 L or larger.

These hybrid machines use electrically driven HiPEx extruders and servohydraulic accumulator heads. The heart of this series is the new clamp design (patent pending) with two diagonal tiebars and a two-stage action that comes in two versions. In the standard servohydraulic version, high-speed platen traverse movements are actuated by a long-stroke hydraulic cylinder, while a larger, short-stroke (5-10 mm) hydraulic cylinder provides closing force.

Alternatively, a hybrid electric version substitutes an electric toggle driven by a servomotor and a ballscrew for the long-stroke hydraulic cylinder. Bekum sources say there is little difference in energy consumption between the fully hydraulic and hybrid clamp versions, but the hybrid clamp offers greater precision and therefore can operate at higher speeds.

In either version, the clamp’s closing position can be set on the BC 8.0 control, as can the mold thickness, which is variable over a large range (patent pending)—something Bekum says is not available on other electrically set clamps for large blow molders.

Molds can be easily and quickly changed from the side by means of quick-change platens and centering devices, Bekum notes. Machines can be equipped with bottom calibration, blowing and blow-pin spreading, as well as horizontal or vertical parison-transfer devices. In addition, Bekum can supply complete systems for products such as 220 L ring drums with molds, robots, post-processing or post-cooling stations and material handling from a single source.

Another addition to Bekum’s industrial line is the all-electric EBLOW 38 shuttle (40 m.t., 720-800 mm stroke), an upgrade of the older EBLOW 37, sharing the updated C-clamp design and other major features of the 8 Series packaging machines. Positioned as Bekum’s smallest industrial machine, it’s available with single or double stations and is suited to molding canisters up to 30 L. Three-station removal and a bottom calibration station are options.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreNew Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreRead Next

How Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More