Injection Molding Troubleshooter: Get the Most from Flow Simulation

Flow-simulation software is one of the most powerful tools ever developed for improving injection molded part quality.

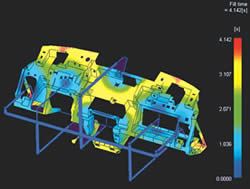

Flow-simulation software is one of the most powerful tools ever developed for improving injection molded part quality. But ever since flow simulation was first commercialized in 1975, molders have been pondering the best way to use it. Many have questioned its usefulness or doubted its accuracy. Those who doubt the accuracy of flow simulation typically have found poor correlation between the computer model and real-world molding results. This may be the result of either misapplying the software or of unrealistically high expectations for its accuracy.

Some people believe in the software’s accuracy but simply question its usefulness. Molders’ common refrain is they do not have the human or financial resources to dedicate to using the software. Or they cannot fit a rigorous mold analysis into their tooling schedules. Their attitude is: “We have a skilled group of engineers and moldmakers. We know what we’re doing, so why spend the money?”

The answer is that as mold-analysis consultants, we see success stories everywhere—from the moldmaker who can save his customer $7500 by eliminating a single hot drop on an auto fascia mold, to the molder who can feel confident in quoting accurate cycle times, to the OEM who can bring his products to market faster by eliminating trial and error. But there are a few pitfalls users should avoid on the road to effective use of mold analysis.

No analysis can be successful without the following three ingredients:

- A well-defined set of goals. This will help determine which analysis software is used to handle the task.

- An experienced analyst that thoroughly understands modeling implications and limitations of the software.

- Excellent communication among all players in a project—product designer, mold designer, molder, material supplier, and flow analyst.

Get Good Information

Too often the client requesting the mold analysis doesn’t provide all the information required by the engineer who performs the analysis. More than a mold or part design is needed—a proper analysis also is based on a developed set of processing conditions. It is helpful to know the molder’s processing habits so that the analyst can try to work within those parameters. For example, if the analyst uses one set of process temperatures and the molder uses other temperatures that he’s more familiar with, the molding results may not match the analyst’s.

The client should inform the analyst about all the nuances in the part, mold, and process. Data that are often missing include how much coolant flow is available to the mold, where a gate can or cannot go, and typical process temperatures used to mold a particular resin. Cooling information is often a particular sore point because mold designers often leave the mold’s cooling layout until the last stages of tool development. Not specifying details like restrictions on gate placement can lead to false assumptions by the analyst. If the client decides afterward to “correct” the gating, he or she may not realize that the analyst’s predictions of moldability may be largely invalidated.

In addition, the client should make certain that the mold builder actually follows the recommendations of the flow analyst. Too often a mold builder may conduct a flow analysis because the client requests it—but then ignores the analyst’s conclusions. Likewise, the filling speeds, process temperatures, and cooling conditions used to predict moldability must be followed when the finished mold reaches the press—or no one should be surprised if the parts do not come out as predicted.

Material Data are Key

Inaccurate material data are a major source of inaccurate flow analyses. An extensive list of appropriately characterized resins has been developed for flow analysis. Even though a major percentage of flow-analysis projects are done using data from these standard resin formulations, clients may shortchange themselves if the analyst substitutes data on a “similar” resin for the one they are molding. New or custo mized materials should be tested expressly for the purpose of a flow analysis.

Clients also don’t always realize that the materials data required for flow calculations are not found on standard data sheets. They can only come from specialized testing. Melt flow index (MFI), for example, is a poor indicator of flow behavior at the much higher shear rates used in actual molding.

Realistic Expectations

Clients need to be aware of what the analysis will and won’t provide. There seems to be a widespread belief that because the analysis is being done on a computer that all of the results will be correct. Another common assumption is that if the analysis does not show what the client was expecting, then the analysis is dead wrong.

The client must realize that this is a simulation. Therefore, there are approximations and simplifying assumptions made by the software that make it impossible to achieve 100% accuracy. However, if all the real-world processing conditions, mold-design details, and material characteristics perfectly match the inputs to the analysis, then one can expect very accurate results. Even if the analysis results are not 100% perfect, one of the most powerful uses of the software is to observe the trends in results based on changing from one scenario to another.

Use the Right Tools

Adding to the confusion or misuse of flow analysis is the proliferation of different software tools, each designed to achieve different goals. Choosing the wrong type of simulation software can lead to disappointment, production delays, mold rework, and overall higher costs.

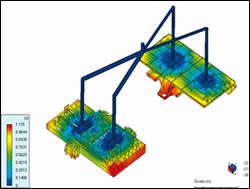

Some of the most common questions answered by simulation software are: Will the part fill? Where will the weld lines be? Where should I place the gates, and what sizes should they be? What size of molding machine is appropriate? Is my cooling design adequate, and what will my cycle time be? How much shrinkage and warpage can I expect?

However, not every software program can answer all those questions—or not with the same degree of exactitude. Some flow simulations are designed for a fast approximation based on minimal data, while others take longer and require more detailed inputs but give more precise information.

Earlier generations of simulation software were appropriate only for “thin-shell” parts like housings and panels. These programs could not realistically model thicker parts. Nowadays, there is software optimized for each type of part.

Justify the Economics

Once you are convinced that the software is technically viable and can be a great source of help in developing a mold, it makes sense to understand the savings that can be realized versus the costs of purchasing the software or outsourcing analysis work. The exact savings can vary greatly from mold to mold, but the following factors should be considered.

What does it cost to pull a mold from production for rework? What are the costs associated with not hitting the quoted cycle time, generating excessive scrap, or filling an order late because of any of those factors? These are all things that can help justify an analysis.

CAE Services Corp. in Batavia, Ill., claims to be the largest consulting firm using Moldflow simulation technology in the U.S. The firm currently conducts 250 to 300 analyses a year, and has done nearly 5000 analyses all told. Mark Solberg is v.p. of sales and marketing, and Tim Lankisch is engineering manager. Contact them at 630-761-9898.

Related Content

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreBreaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More