Keep Molds Running Longer

New low-friction, high-hardness coatings and upgraded deposition technologies are expanding the range of surface treatments to help tooling stand up to tougher molding challenges.

Hard chrome and electroless nickel plating remain the two most popular surface treatments used to protect molds and mold components from wear and corrosion. However, highly engineered coating technologies continue to evolve in response to more complex tooling geometries with tighter dimensional requirements, the need to avoid galling between tool components, and the aim of improving polymer flow and part release.

Many types of mold coatings based on a range of metals have been available for the last two decades, and at least five more have appeared in recent years. Growing use of high-performance resins containing higher percentages of glass and mineral fillers, metal powders, wood fibers, flame retardants, and other potentially abrasive or corrosive materials are making these higher-end coatings worth a second look. They can impart at least 10% higher resistance to wear and corrosion while raising release performance by a similar amount. The thin metal films can also reduce maintenance and extend tool life.

Sources of mold troubles

Tool corrosion can be caused by water leaks contacting untreated mold surfaces, seeping through micro-cracks, or condensing in the mold (perhaps due to chillers running too cold), as well as spillage from ill-fitting o-rings and pipe fittings, or from hoses during hook-up, says Mike McCabe, marketing manager for Bekaert, a supplier of mold coatings. In addition, chlorine- or bromine-containing resins and additives can become corrosive due to overheating. Inadequate venting also causes accelerated corrosion by causing trapped gases to score tooling components.

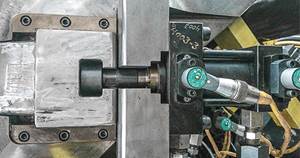

Contact surfaces that are of highest concern include A & B plates, ejector plates, support-column rails, gates, leader pins, hot runners, surfaces directly opposite a gate, and cavity-and-core sets. Moving pieces may present problems of galling or abrasive wear—such as valve gates, shut-off nozzles, threaded cores, ejector pins, core pulls, and slides. “The life of parts like slides and ejector pins is becoming a bigger issue. Molders are realizing that the proper coating for these components helps them achieve productivity gains and higher quality parts,” says Dwayne Douglas, product manager for mold and dies at Balzers, another coating supplier. These concerns have led to development of materials with low surface energy, low friction, and/or lubricious surface characteristics.

Tried and true

Hard chrome and electroless nickel are old standbys that are likely to remain major players for some time to come. Hard chrome has 72 Rockwell C hardness (HRC) and is applied at 130 F. It is a proven defender against wear, even from plastic compounds containing up to 40% glass. It has an 0.2 coefficient of friction (COF) against steel, and though chrome plating does not always deposit uniformly, it builds thicknesses up to about 0.0005 in. However, plating non-uniformity and the presence of micro-cracks can eventually cause the coating to wear down, so vigilant inspection and maintenance are required.

Electroless nickel has 50 HRC hardness, lower than chrome, and a higher coefficient of friction of about 0.45. It is applied hotter, too, at about 185 F. But it coats uniformly in thin deposits up to 0.0003 in. It is used on components with more critical dimensional tolerances and for precisely sizing cores and cavities, as well as for dimensional build-up under flash chrome coatings. Chrome chiefly brings wear protection while nickel delivers corrosion resistance. Newer engineered coatings are designed to give the mold maker the best of both worlds, and in some cases added lubricity, too.

Engineered coatings

There are seven categories of mold coatings: thin intermetallic, PTFE-infused metallic, metallic/PTFE co-depositions, metallic plating, surface-hardening treatments, thin-film hard coatings, and impregnated polymers. The various types can be applied to the metal substrate using a chemical bath in an electrolytic or electroless process (with or without anodes), or via vacuum chamber using physical vapor deposition (PVD), chemical vapor deposition (CVD), or plasma-assisted CVD (PACVD). Application temperatures can range from ambient to 1850 F or more. Coating thicknesses can be more or less uniform, depending on the process, and range generally from less than 0.5 micron to 8 microns.

Some of the more recent coating developments start with chrome or nickel and combine them into a composite, alloy, co-deposit, or “matrix” with particles of diamond, boron, titanium, cobalt, phosphorus, tungsten, or PTFE. Nowadays, different types of coating materials may be employed in the same mold to yield special performance properties such as thermal conductivity or heat dissipation. Some of these metal films are used to harden the surface of softer heat-conductive metals such as beryllium-copper. In some cases molds made from lower performing steels can be made to perform like a higher-end tool steel.

These advanced coatings are developed through proprietary bath chemistries and new vacuum-chamber technologies that use PVD, CVD, and PACVD. “Application technology is driving the development of tool coatings that are more durable at reduced thicknesses, bring improved lubricity to aid release of extremely tight-tolerance parts, or protect better against erosion and corrosion,” says David Bell, CEO of Phygen, a coating service supplier with an advanced, patented process.

The proper selection of a coating is based chiefly on how much surface hardness is required, the level of wear resistance and lubricity, whether the mold has a smooth or textured surface, and the type of resin or compound being molded. Coating application temperature and layer thickness are also issues, as higher deposit temperature or a build-up of coating material can affect substrate dimensions. Several companies have developed new coatings to tackle these new requirements. At least one supplier has developed a new ion-implantation technology that can deposit a hard metal coating onto surfaces as light and soft as paper without damage.

Ion implantation today

Ion implantation has been available as a tool surface treatment for two decades. The latest version is the Ionic Plasma Deposition (IPD) process from Ionic Fusion. The company’s four-year-old IPD process impregnates and coats the tooling surface with metal using controlled energy from a plasma source at a lower temperature, eliminating peeling or flaking, says v.p. Vincent Sciortino. The process is capable of implanting most metals—from aluminum and chromium to titanium and zirconium—into a wide range of substrates. The process can be optimized for the substrate composition and the amount of wear, corrosion resistance, or lubricity required.

The process takes place in a digitally controlled vacuum chamber containing a source of the metal to be implanted. The tool component is first cleansed in an ultrasonic bath, then placed in a fixture in the chamber. A vacuum is drawn to remove contaminants, water vapor, and oxygen. A plasma (ionized vapor) is created to enable ion bonding to the substrate. The plasma ionizes the source material and guides it into the substrate at high energy. These ions can be combined with reactive gases to create hard, lubricious nitrides and oxides. Ionic Fusion can create a coating from sub-micron to 5-micron thickness. A 3- to 5-micron coating is typically sufficient for most applications, says Sciortino.

Impregnation of the substrate can take place at low temperature (around 158 F) where required. This allows deposition of harder alloys into softer metal substrates such as beryllium-copper without distortion of the tool dimensions or grain structure.

The IPD process can implant a range of alloys atom by atom in the surface of the tool, delivering a spectrum of performance enhancements including higher abrasion and corrosion resistance, oxidation resistance, and improved heat dissipation.

Ionic Fusion typically uses zirconium nitride for sliding wear applications due to its low COF and high durability. Zirconium nitride impregnation can raise tool steel’s surface hardness to an equivalent of 85 HRC. The sliding COF is less than 0.16 (versus 0.7 to 0.8 for and untreated steel) when both surfaces are treated with zirconium nitride, says Sciortino. Multi-layer deposition of different metals can be engineered to improve wear and corrosion resistance as well. The lubricity and hardness of the coating may enable faster molding cycles, says Sciortino. Moldmakers can purchase an IPD machine and a license for the process or contract with Ionic Fusion to treat their parts.

New, thin & tough

Several new coating technologies are now commercially available. A three-year old PVD process delivers a chromium nitride coating that is less brittle than conventional hard coats and provides high adhesion, hardness, toughness, and a relatively low COF. Developed by specialty coating maker Phygen, the proprietary technology uses patented arc-plasma accelerators to create a higher plasma density with intensive low-energy ion bombardment under tightly controlled conditions. It produces a high-performance coating that boasts more uniform grain structure and extremely high adhesion to the substrate, according to CEO Bell.

This FortiPhy UltraEndurance coating is a low-friction coating for hard-to-maintain textured tool surfaces. It reportedly improves mold filling and part release. The coating can be applied as thin as 0.00015 in. in a modified line-of-sight process that permits coating deeper holes or very small and detailed areas (with masking). The coating is a fine-grained and dense nano-crystalline structure, with a coefficient of friction of less than 0.1. It is chemically and thermally stable in air at up to 1550 F. The coating reportedly also provides corrosion resistance similar to that of stainless steel, while its micro-hardness exceeds that of conventional PVD chromium nitride (CRN) coatings, according to Bell. He adds that other PVD technologies can leave less uniform coatings and voids.

The coating is applied at 950 F, which is suitable for tool steels such as H-13 and D-2 types. Phygen also has a lower-temperature coating process (700 F) for other substrates.

Phygen recently developed two new multi-layered titanium-aluminum and titanium nitride coatings (VeriPhy and CertiPhy) that are said to deliver excellent release properties but are not as abrasion resistant as the FortiPhy coating. These two coatings were developed initially for die-casting molds but now have been applied to injection molding tools as well.

Meanwhile, Balzers rolled out a new titanium-aluminum nitride tool coating for processing glass-reinforced resins and for protecting low-hardness (40 HRC) steels with textured surfaces. Available for about three years, its newest coating, called Balinit Lumena, brings high wear protection even under high mechanical stress and has a COF from 0.30 to 0.35, according to Dwayne Douglas. This coating is applied 8 to 10 microns thick and has a high maximum service temperature of 1650 F. Balzers offers several types of titanium-based coatings, including the well-known titanium nitride (TiN).

Poly-Plating is developing a nickel-boron coating with higher hardness than its standard Poly-Ond nickel-PTFE coating, says company president Edwin Ondrick Sr. “The use of boron would raise the hardness by 10 points to about 80 Rockwell,” says Ondrick. That would suit it to use with glass-filled materials or customers seeking the greatest tool longevity. At present it is too early to determine the optimal process temperature, coating thickness, and final properties, says Ondrick.

Diamond—A mold’s best friend

Diamonds are the hardest substances in nature, so it is no surprise that they play a role in today’s protective mold coatings. An example is Armoloy’s XADC diamond-chromium coating, which provides surface hardness of 98 HRC. A coating 0.0001 to 0.0003 in. thick is applied in a chemical bath at temperatures under 200 F, eliminating concerns of annealing and substrate distortion, says Michael Bejbl, president. The coating is a combination of Armoloy’s TDC chromium coating with the addition of spherical diamond particles. The surface film adheres strongly to most metals except aluminum, magnesium, and titanium and performs at up to 1400 F. Its corrosion resistance exceeds that of 440C stainless steel, and its COF is 20% lower than Armoloy’s standard thin, dense chromium (TDC), says Bejbl.

Bekaert’s Dylyn diamond-like coating (DLC) is made by replacing some carbon-hydrogen chains with silicon-oxygen chains. Bekaert purchased the technology in 2000 from Advanced Refractory Technologies to improve its line of diamond-like coatings. “There is some variety among diamond-like coatings, with the adhesive layer being a main difference,” says Bekaert’s McCabe. “You must have an adhesive layer for the coating to adhere to the substrate. Without this layer, stresses in the coating will build up and cause it to pop off.” McCabe says Dylyn’s adhesive layer creates a smooth, conformal DLC able to replicate the tool surface exactly. The amorphous structure of diamond-like coatings delivers corrosion protection, he adds.

Engineered mold coatings can speed mold filling and ease release, as shown in these results for WS2 tungsten disulfide coating from Micro Surface Corp.

Two or three years ago, Bekaert also developed DLC-A, a coating for beryllium-copper, which does not readily form bonds with carbon. “This coating brings surface hardening to beryllium-copper,” says McCabe.

DLCs are typically 2 microns thick, with a hardness from 80 to 90 HRC and a coefficient of friction from 0.05 down to 0.12. DLCs are used in many sliding mold components like ejector pins, unscrewing cores, and sleeves, especially in medical and food-contact applications where lubricants cannot be sprayed onto the mold, says McCabe.

One of Balzers’ newest coatings is a diamond-like carbon designed for use with highly abrasive plastics or for moving mold parts. Its Balinit Triton coating, commercially available for about four years, combines hardness above 60 HRC with a COF of 0.10 to 0.20. It provides good abrasion and corrosion resistance, even with a minimal quantity of lubrication, says Douglas. Maximum service temperature is 650 F. Typical coating thickness is between 0.5 and 4 microns and the coatings do not alter sharp edges or mirror finishes when applied, he says. The coatings require no finishing, Douglas notes.

One of the newer coatings in Bales’ line is Dia-Clust diamond-chrome. It consists of nanometer-size, spherical diamond particles in a chromium matrix. It has a hardness greater than 85 HRC and is applied at 130 F, so it can coat prehardened, heat-treated, or nitrided steel and aluminum, beryllium-copper, brass, and stainless steel, according to president Steven J. Bales. He says diamond-chrome is easily strippable, has good lubricity (0.15 COF) and anti-galling properties, and can be applied at any thickness from 20 millionths of an inch to 0.001 in., so it can coat complex mold details.

Chrome coatings advance

Armoloy developed its new Bi-Protec metal film for highly corrosive environments with the potential for severe wear. The co-deposited coating is a combination of electroless nickel and hard chrome. It is deposited in a chemical bath at 180 F to a thicknesses from 0.0002 to 0.004 in. Coating thickness is said to be uniform to ±0.000050 in.

Another new plating in development is a nickel-cobalt coating from Nutmeg Chrome, though few details were available at press time. (Bales Mold Service also has a nickel-cobalt coating called NiHard, which boasts 62 HRC, 0.24 COF, good corrosion and abrasion resistance, and uniform deposition on fine details.)

New roads to higher lubricity

In 2004, Bales introduced Nibore, a co-deposited nickel and boron nitride metal film that combines the uniform coverage of electroless nickel with the lubricity of boron nitride. The coating is applied in an autocatalytic process, therefore no anode is required, saving the time to build the anode. It is applied at 185 F and yields a 67 HRC and a COF of 0.05. Nibore is suited to zero-draft parts or others that are difficult to eject. The film also has high wear and corrosion resistance and can withstand temperatures up to 1250 F without degrading. “This surpasses the 550 F maximum for all PTFE coatings,” says Steven Bales.

Bales Mold Service is developing additional co-deposited films, such as silicon and carbide or nickel and silicon, that would yield higher surface hardness.

Micro Surface Corp. says it will unveil a new release coating that combines the hardness of its WS2 tungsten disulfide coating with the corrosion-fighting kick of its Nicklon-Plus co-deposited nickel/PTFE coating. The result will deliver very low COF for easy release. The new coating also will go on thinner than the WS2 coating or the firm’s Nicklon-Plus (both about 0.5 micron) but deliver similar properties, says Ed Fabiszak, president. Nicklon-Plus and WS2 coatings are deposited in a chamber at around 200 F using a plasma assist.

A new plasma-assisted PVD titanium coating being developed by Balzers is applied at temperatures below 600 F, making it suitable for use with softer tool steels.

Forestek Plating offers a special version of its TFE-Lok PTFE coating whereby PTFE particles are infiltrated into titanium nitride instead of into hard chrome. The standard hard-chrome version heats the chrome plating to expand the pores and then infiltrates cryogenically cooled PTFE particles under high pressure at around 325 F. The hard-chrome version of TFE-Lok coating brings a 0.04 COF and 58-70 HRC. It is applied at 0.0002 to 0.003 in. The version using titanium delivers even higher hardness, but the application temperature is higher and the thickness greater, says Tom Forestek, president.

Related Content

The Impact of Hydraulics on Tool Design -- Part 1 of 2

Get a better understanding of their use, proper sizing, and how the tool design and setup in the machine can impact failures in manufacturing.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreMedical Molder, Moldmaker Embraces Continuous Improvement

True to the adjective in its name, Dynamic Group has been characterized by constant change, activity and progress over its nearly five decades as a medical molder and moldmaker.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More