Making Safety Profitable

Worker safety and health are every molder’s responsibility, but the approach taken by Mack Molding Co., Arlington, Vt., helped it gain significant production and revenue returns.

Worker safety and health are every molder’s responsibility, but the approach taken by Mack Molding Co., Arlington, Vt., helped it gain significant production and revenue returns. Mack’s safety efforts also earned it the state’s highest safety honor last year, the Governor’s Workplace Safety Award. “It is given by the state of Vermont in recognition of an employer’s commitment to excellence in workplace safety and health,” said Kevin Dailey, director of human resources.

Health makes wealth

One of the most dramatic examples of the success of its safety program is the “uptime” of its employees. Each of its three custom injection molding plants in Vermont set records for consecutive days without a lost-time injury. Mack’s Arlington headquarters plant reached 179 days; its East Arlington plant achieved 209 days; and its Cavendish facility hit 365 days. Having its labor force healthy and able to work keeps Mack’s manufacturing operations on schedule while trimming worker compensation costs.

The cost per man-hour for worker compensation claims at the Vermont facilities fell 84% from an average of $1.24/hr per employee in 1999 to an average of just 20¢/hr per employee from 2003 to 2006, says Dailey.

Mack generated $277 million in sales at the end of June 2006, operating with 1850 employees and 121 injection presses. Mack has a total of seven manufacturing plants and three distribution and remanufacturing facilities globally.

A culture of safety

Mack said it was proactive regarding safety and took several steps over the past five years to enhance its Loss Prevention and Safety program. Its biggest move was to hire a full-time occupational health nurse and a part-time occupational health physician to serve the three Vermont facilities. The company established safety committees that meet and review policy and procedures quarterly. Mack even set up a medical emergency response plan, which includes 38 employee volunteers who are American Red Cross certified to perform standard first aid.

Mack’s safety program is organized around regulatory compliance programs and issues. Members of the plant manager’s staff at each facility create programs designed for each department. The programs cover a range of issues such as lockout and tagout, forklift safety, and personal protective equipment.

“A significant improvement in worker safety is realized by having on-site services of a physician and an occupational health nurse, who help to develop and maintain the safety programs,” says Dailey. The on-site nurse, Kathy Hall, is a vital contributor to the safety program at each plant. She helps minimize workplace hazards by conducting tests to assess health risks. Given the new attention that industry and safety agencies are paying to workplace ergonomics, Hall reviews the physical requirements of all job descriptions and started a job-rotation program for the more physically demanding positions.

Mack says worker wellness is also an important part of safety. It has installed fitness facilities at all of its plants, and the on-site nurse also carries out blood-pressure, hearing, and vision screenings and administers flu shots. “Our employees are our most valuable asset, and when they are healthy they positively influence our bottom line and our ability to compete,” says Dailey.

Mack also hosts a variety of events and awards to recognize the effort required of each employee to maintain safety in the plant. Events include sit-down luncheons served by management, and raffles for DVD players, gas grills, or gift cards.

Related Content

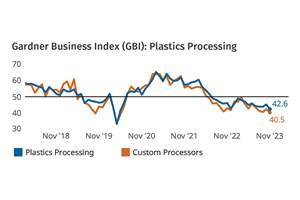

Plastics Processing Activity Contracted in July

Plastics processing GBI contracted for the third month in a row.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MorePlastics Processing Activity Drops in November

The drop in plastics activity appears to be driven by a return to accelerated contraction for three closely connected components — new orders, production and backlog.

Read MoreProcessing Activity Dips in May

Plastics processing took a downturn in May, the first appreciable dip since November 2023.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More