Molded-In Fabrics Give New Look and Feel To Electronic Enclosures

Inclosia Solutions, a unit of Dow Chemical Co., claims to have found a better way to integrate denim, suede, leather, fur, lace, velvet and other fabrics into the surfaces of enclosures for portable devices like cell phones, laptop computers, and pocket calculators.

Inclosia Solutions, a unit of Dow Chemical Co., claims to have found a better way to integrate denim, suede, leather, fur, lace, velvet and other fabrics into the surfaces of enclosures for portable devices like cell phones, laptop computers, and pocket calculators. The product-development company says its EXO system, a variant of two-shot overmolding, is more efficient and cost-effective than conventional one-shot insert molding for mating fabrics to enclosures molded of polycarbonate, ABS, and PC/ABS.

“Performance features are no longer the sole differentiator in electronics purchasing,” says Tom Tarnowski, Inclosia Solutions’ global business manager. He argues that the visual and tactile appeal, enhanced by molded-in fabrics, is increasingly important to marketing of consumer electronics. OEMs can exploit fabric decoration to define and strengthen the brand identity of their newest products. Costs are relatively low, since the same tool can be used to incorporate many fabric and color combinations.

Overmolding refined

Fabrics have long been insert molded into parts such as automotive floor panels, door liners, and seat components. The usual approach is to insert fabric or carpet in the tool and then back it up by injecting plastic behind it. But fabric-plastic moldings generally don’t achieve quality standards required for consumer enclosures, often showing wear and fraying at the edges. Also, it is critical in electronic enclosures that the fabric be isolated from the interior, since encroachment can cause short-circuits or compromise compliance with UL flame-resistance requirements.

Tarnowski says the EXO process addresses those deficits. It begins by creating fabric blanks or preforms. These are reinforced with laminated film and adhesive backings that minimize fabric degradation, wrinkling, or misalignment during overmolding. The fabric blanks can be used either as flat inserts or can be thermoformed into 3D shapes for more complex applications.

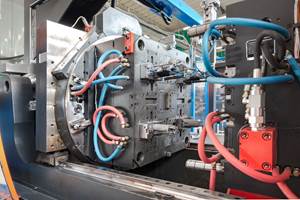

Next, the preforms are loaded robotically into a standard two-shot molding system. The first shot is typically a rigid material that provides a solid backing for the fabric. The second shot overmolds the edges of the preform to seal the perimeter of the fabric (preventing wear at exposed points) and to incorporate molded-in anchors that more firmly fix the fabric in place. This second shot can be of a different (softer) material and/or color. It also opens the door to improved functionality, says Tarnowski. For example, overmolded layers can act as gaskets to provide a water-tight seal.

Inclosia Solutions has set up design and engineering bureaus in the U.S. and the Netherlands, and it plans to add a third in Asia shortly. The company offers electronics OEMs a one-stop source for design, material selection, tooling, prototyping, assembly, and production. For this purpose, Inclosia Solutions has formed a collaborative alliance with Eimo Oyj in Lahti, Finland, a designer and molder of enclosures for telecommunications.

Related Content

Electric Injection Molding Machine Line Expands

Boy will debut three new models in its Electric series of machines, which feature a redesigned and more compact drive and inverter technology.

Read MoreArburg Open House Emphasizes Turnkey Capabilities

Held at the company’s U.S. headquarters in Rocky Hill, Connecticut, the event featured seven exhibits, including systems that were designed, sourced and built in the U.S.

Read MoreTederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More