Molders Go ‘Rapid’ for Prototyping and Manufacturing

Three forward-thinking custom molders have taken steps to streamline their manufacturing, expand new product development, and add to their customer base—and all in a more cost-effective manner than ever before.

Three forward-thinking custom molders have taken steps to streamline their manufacturing, expand new product development, and add to their customer base—and all in a more cost-effective manner than ever before. What’s their secret? These three have invested in a category of technology commonly called “rapid prototyping” (RP) and also coming to be known as “additive manufacturing” (AM) because it can be used for short-run manufacturing of production parts. By going in-house with this technology, these molders exemplify what may become a new way of doing business for many others in the future.

Two of the three are injection molders that also operate their own RP/AM operations: Minneapolis-based Spectrum Plastics Group and Thogus Products, Avon Lake, Ohio. In Spectrum’s case, capability for RP/AM and for building injection molds with this technology (“rapid tooling”) were enhanced through its acquisitions in 2008 of Dynacept in Brewster, N.Y., which specializes in RP, quick-turn molding or manufacturing (QTM), and the new Dynaclass Quick-Turn tooling system; as well as Protogenic of Westmister, Colo., a prototyping service bureau. Last year, the Dynacept QTM operation was moved to Spectrum’s Ansonia, Conn., facility, a full-service injection molder and tool builder, while the rapid prototyping operation was combined with that of Protogenic in Colorado.

Meanwhile, Thogus saw a heightened demand for RP/AM after it acquired its first Stratasys FDM (fused-deposition modeling) system a few years ago. In 2011, company president Matt Hlavin launched a separate RP/AM company, rp+m, housed within the Thogus facility.

Among the key markets served by both these companies is healthcare and medical devices. Tim Erwin, senior technical advisor at Spectrum’s Ansonia facility, pegs this market sector at about 30% of the company’s business, while aerospace/defense is about 50%, followed by a smaller business segment described as “precision industry,” which ranges from automotive to lighting.

Thogus also serves consumer products, electronics, industrial, food and beverage, lawn and garden, and plumbing markets. But, the medical market is significant enough to be housed in a newly launched subsidiary, Jalex Medical. Hlavin expects this business to grow to over 60% in the next five years, and he sees AM as having significant potential in medical device development.

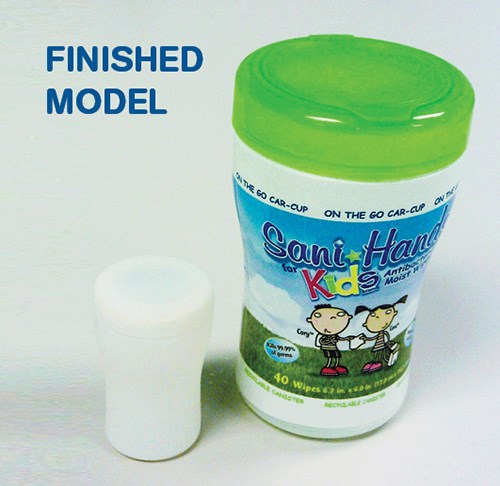

The third molder, Currier Plastics of Auburn, N.Y., is a custom injection molder and blow molder, primarily of packaging, and a new kid on the block in terms of in-house RP. The company acquired significant experience with the technology during its initial foray into proprietary product development, going through 10 digitally printed prototypes to arrive at the final design of its PerfectSit lumbar-support seating device (see Jan. ’12 feature article).

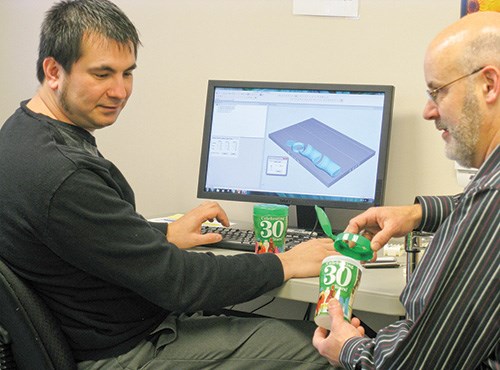

That first experience with RP—through an outside service bureau—was enough to sell Currier on buying its own unit. Since its acquisition last year of an Objet 30 3D digital printer (sold by Stratasys LLC, Minneapolis, following its recent merger with Israel’s Objet Ltd.), Currier has already added several notches to its belt in terms of both experience and business expansion.

Spectrum Plastics Group

Addressing Spectrum’s decision to acquire two RP/AM companies, director of marketing Tim Nakari says, “We have been asked to provide more value to the product development and production process than just supplying parts. Our customers need a partner in product development who can provide design feedback, physical prototypes, and a number of “bridge” production solutions prior to full-scale tooling and molding, so that’s the service we chose to provide.

“The second reason is the clear differentiation this additional offering provides,” Nakari continues. “Our combination of both Quick-Turn tooling and production-level tooling, and our capability for merging the two, makes what we do as unique as it is compelling.”

Quick-Turn tooling was so named because it offers shorter lead times than multicavity production tooling but offers sufficient quality to be used as a “bridge” tool for limited production until the production tool is built. Nakari says it provides lower part quantity than a production mold, but higher quality than typical rapid tooling.

Spectrum’s Tim Erwin explains that the company’s original business plan was to roll divergent plastics companies into one complete “spectrum” of services from product design advice and guidance through production services—molding, decoration, assembly, packaging, ship-to-stock. “One tool in our toolbox is the RP business. We aren’t and never intended to be a major supplier of RP services. We offer RP as part of a total package.”

According to Erwin, many businesses have made the mistake of trimming back on engineering and now need assistance in the basics—most notably in plastic part design and material guidance. “Many concepts come to us devoid of any common and well-developed plastics design principles. Usually, after getting over a rough patch of patiently explaining why the product is not moldable or producible, we can offer to steer the customer closer to something it can actually mold and manufacture.”

Typically, this involves a fee, but not always. Customers that partner up with a full-service supplier can have this cost rolled into the program. Erwin adds, “This is a very touchy area, and you can get duped pretty easily if you’re not on your toes. Customers love ‘free stuff,’ and some try to get you to offer design-change suggestions up front so they can get apples-to-apples quotes from a number of suppliers. However, if you can avoid these pitfalls, integrated RP is a powerful sales tool in quoting a complete package of engineering services through production.”

Challenges cited by Nakari include educating Spectrum’s client base and its own sales and program-management teams about its RP capabilities and about how Spectrum’s Quick-Turn tooling and Dynaclass system differ from other rapid-tooling services. A series of sell sheets, a capability matrix presentation, and an iPad application were all created to bridge this education gap.

Erwin emphasizes the value of RP in the design process, particularly when dealing with customers who may not have much clue as to what their parts will look like. The RP parts give them a first look. “RP is great for appearance models and even better for landing a contract. We have visited prospective customers where we’ve reviewed their designs, offered suggestions, and are meeting their team face to face for the first time. Whipping out a set of stereolithography 3D models (yes, for free!) for them to be able to see and touch their product is a great way to land a deal. In-house RP makes this easy and doesn’t really cost that much.”

Many customers use RP parts for product testing and the Spectrum team will provide careful guidance, as RP parts don’t really replicate the properties of injection molded parts. Inappropriate testing could condemn an otherwise sound design, cautions Erwin.

Spectrum also uses RP, usually stereolithography (SLA), for fixture designs (assembly, ultrasonic welding, heat staking) to get a leg up so that they are 95% ready when the first parts come off the molds. “I’m able to reduce my fixture build time from weeks down to a few hours, adding finishing touches and really compressing a product development cycle,” Erwin notes.

Nakari says the decision whether to injection mold or use RP/AM depends on the customer’s needs and the intended end use. Material is typically the first deciding criterion. “If a specific material, such as PEEK or another implantable medical resin or a specific engineered plastic is required, then Quick-Turn tooling and molding is likely the logical choice. Unless the quantity requirements are so low that CNC machining is a viable option. So we look at quantity as the second factor in determining the best solution.” He adds that if material is a flexible factor at this stage of development, Spectrum will consider other RP methods such as SLA, 3D printing, SLS, or casting either silicone or urethane, taking into consideration cost, mechanical properties, and cosmetics.

Thogus Products

With the formation of its two new companies, rp+m and Jalex Medical, Thogus is continuously evolving and redefining itself. Acquiring in-house RP/AM capabilities had been on the radar for some time, according to marketing manager Dana Foster. “Our president, Matt Hlavin, followed Stratasys for 10 years (stratasys.com) and saw the value AM would add for our customers. We wanted to be more than just one more molder among 8000 in the U.S., not to mention the rest of the world. Not only were we able to provide quotes, but we were able to show up at our customer with a quote and their part in our hand. Our customer would be able to touch and feel their part before spending money on tooling. It also enables us to show easily whether there are issues with a part design or how a part should be redesigned for manufacturability.

“It was an easy decision to purchase our first Stratasys FDM machine in 2009. Growing beyond that was driven by customers who were willing to pay for the service and our ability to use the process in-house. As an injection molder, we were quickly able to produce holding fixtures for quality inspection and assembly, as well as components for robot end-of-arm-tooling.”

Currently Thogus’ rp+m company has six Stratasys FDM machines and one Objet Connex500 inkjet-style 3D printer. From the start, the company also saw the value of equipping itself with every material that Stratasys offers—ABS, PC, PC/ABS, Ultem polyetherimide (PEI), and polyphenylsulfone (PPSU)—so that it would be able to handle the concept ideation, functional prototyping, prototype tooling, end-of-arm tooling, and final production for clients.

Is demand for AM creeping up on RP? Engineering manager Patrick Gannon says the parts made on the Stratasys FDM units by rp+m for Thogus clients are primarily AM production parts. For rp+m’s outside (non-Thogus) customers, Gannon expects an even split this year between prototype and production parts, whereas last year it was about 65% RP/35% AM. “We’re working on projects this year developing new materials to allow the use of AM parts for the aerospace industry.”

As for the limitations of RP/AM, Gannon notes, “Our biggest challenge has been extending the materials we can process to include some of the more highly engineered types we run in molding. However, we have grown from this challenge to go above and beyond the materials offered by Stratasys and helped develop new materials.” In fact, rp+m received an Ohio Third Frontier Grant in conjunction with the Univ. of Dayton Research Institute, PolyOne Corp., Stratasys, and GE Aviation to continue developing new materials for AM.

Whether or not a part is suitable for for AM includes part size, quantity, quality required, timeline, and material requirements. “Unfortunately, there is no easy formula to make that determination. If a customer comes to us for molding low quantities, we always do an analysis on whether RP/AM or injection molding will be more economical for them,” explains Gannon.

Meanwhile, Thogus is quite intent on growing its AM capabilities. Says Foster, “In the future, we see ourselves having more AM machines than injection molding presses. As a strategic partner in NAMII (National Additive Manufacturing Innovation Institute), we are excited to be a part of new processes and materials that are developed in the future.”

Currier Plastics

Coming to appreciate the value of in-house RP took barely any time at Currier Plastics. Last April, it acquired an Objet30 desktop 3D printer, which can make prototypes with materials that simulate ABS and PP. According to Max Leone, v.p. of business development, a key driver behind that purchase was the firm’s growing use of external RP services. Lead times with service bureaus was always an issue, and there were a lot of variables, such as finishing, that could not be controlled. Lastly, one of their external sources that had provided high-quality prototypes was sold to another concern, after which the quality of prototypes declined significantly enough to be noticed by Currier’s perspective customers.

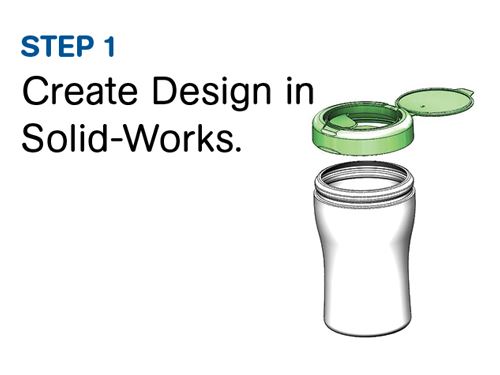

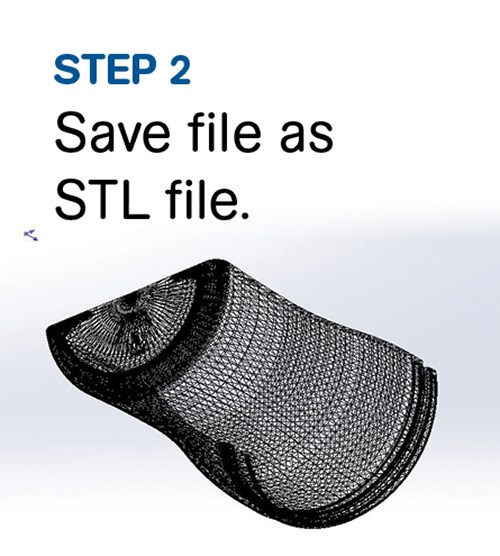

According to Gary Kieffer, v.p. of new product development, Currier spent a couple of years searching for a digital 3D printer that would best meet its needs. “As both an injection molder and blow molder of packages, we wanted to prove to our customers our product design capabilities with a 3D fit-form-function prototype that can be verified before making a costly steel mold.”

The Objet30 unit can make parts within an envelope of 300 x 200 x 150 mm. Currier uses Durus White, a PP-like material that addresses a broad range of applications requiring PP’s appearance, flexibility, strength, and toughness. Currier also use Vero White, an opaque, rigid, ABS-like material that offers toughness, dimensional stability, and greater detail visualization.

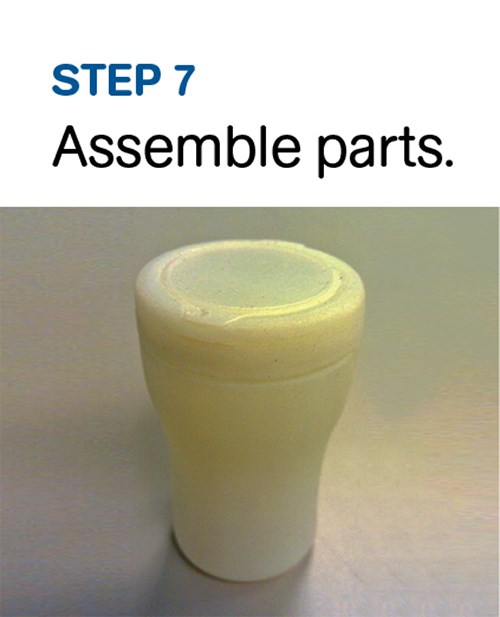

Says Larry Jedik, designer/CAD engineer, “We make different size bottles for personal-care lotions. With the Objet30, if a bottle is too large, we make it in two pieces, which we then assemble. It all depends on the size and shape of the bottle. This unit allows us to print a 3D prototype up to 6.5-7.0 in. We have used a cardboard box to simulate the exact footprint of what we can create on Objet30, which we present to customers to show the dimensional limitations.

According to Currier sources, the RP unit essentially paid for itself when it helped the firm win the contract for a revised model of a hotel amenity package. Says Leone, “We made the modification to the package design—a blow molded bottle with an injection-molded closure—on CAD, sent it to the Objet30 printer, and, two hours later we were able to hand the customer a prototype of the revised product. Key in the redesign was our ability to design a closure that fit well into the container.”

Within the first eight months, the Objet 30 was used to validate designs for 24 different packages, either injection or blow molded. But the number of actual prototypes produced during this time was much higher, as Currier typically makes as many as five duplicates or variations of a design. Says Kieffer, “The beauty of this capability is that once a design has been approved, we can provide multiple 3D parts for our customers’ internal use and to give to their customers, as well as duplicates for our business-development manager and our injection molding or blow molding tool makers.”

To date, Currier uses this unit to validate design geometry and build a prototype in hours or a day. Soon, Currier plans to use the 3D printer to make part fixtures for automatic quality inspection.

Related Content

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

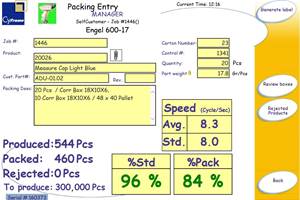

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MorePolyJohn Turns to Blow Molding, Doubles Its Productivity

Leading maker of portable sanitation products knew thermoforming, sheet extrusion, rotomolding and injection molding. Then it found the missing link to higher productivity and new markets: blow molding.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More